Hi Jason

I dont think i posted twice , one was the page Micheal linked to the " two stage reg page" , the second attempt was to the the company home page because i thought i had gone about it the wrong way , which i had twice! no less !!

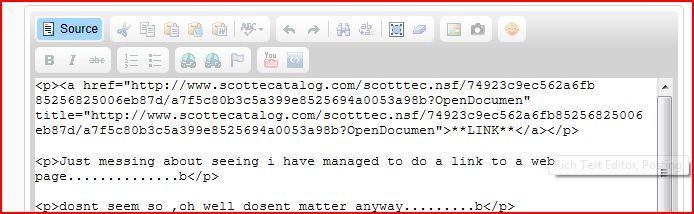

Pretty sure i got it now , must make sure everything matches in the URL box……….b

Well all the links go to the page i was trying to link to now , so will just check the procedure a time or two to see i got i right , just wont hit the post button,…. till. the next time i see something to link to……..b

Edited By bodge on 25/12/2016 13:00:58

Yes i think i got it , i should scrolled the address bar line along a bit to catch those last couple of letters, then pasted to the URL ………….b

Hi Jason not sure how that happened , i guess i must have got something else wrong too ! …..any idea what i got wrong? i"m guessing i must have double tapped some where !……….b

Edited By bodge on 25/12/2016 13:13:37

Edited By bodge on 25/12/2016 13:22:13

Ajohnw.

I do have a vague idea of what to do with it if it is – with a medium sized but.

I do have a vague idea of what to do with it if it is – with a medium sized but.