Posted by James Alford on 12/11/2020 17:34:54:

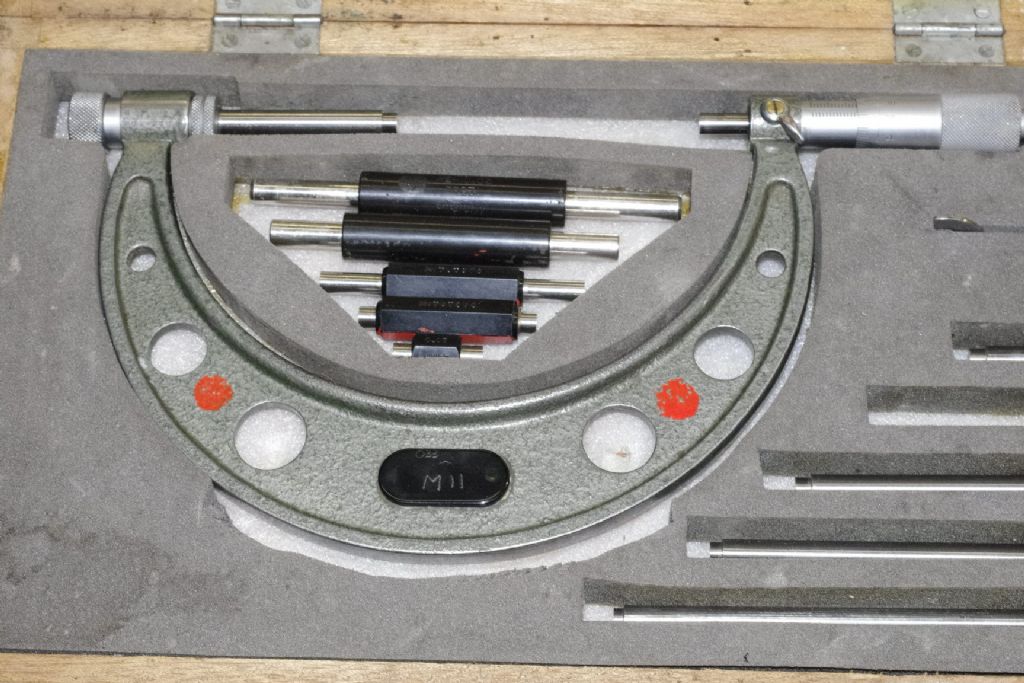

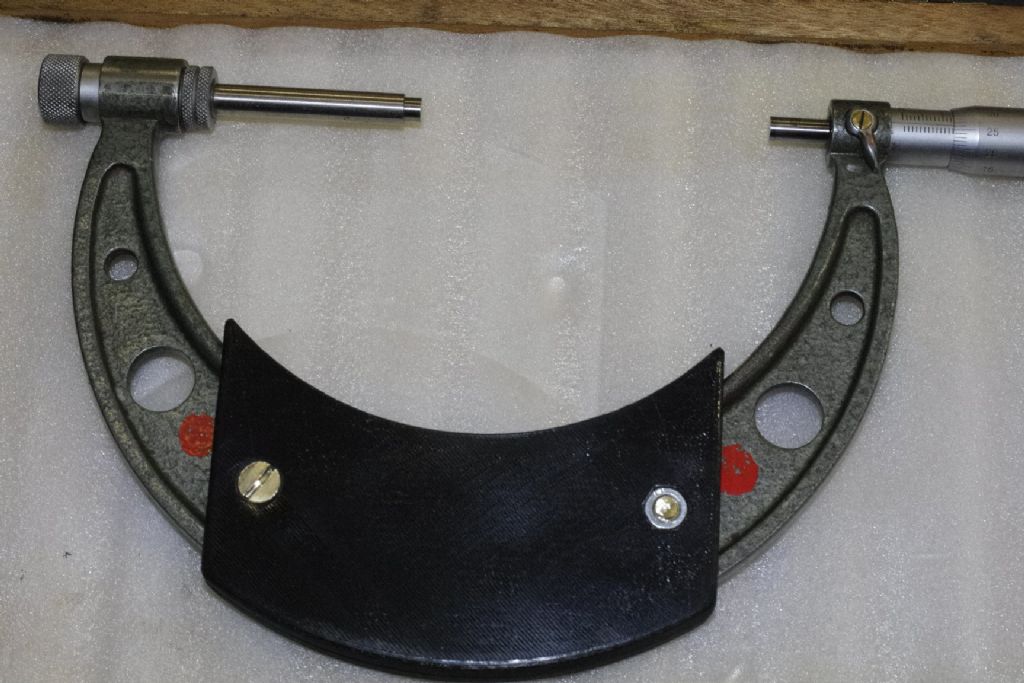

I have bought some second hand 2", 3" and 4" micrometers. Is there any way to check that they "zero" correctly without using a block of known size?

…

Not really, but it's revealing to compare the three micrometers by measuring some ordinary blocks in various combinations. Setting Zero to read zero is usually a simple adjustment, but second-hand micrometers are liable to be worn or damaged beyond hope of achieving their original specification. For instance, the thread is likely to be worn over the range it was most used over, so a 4" micrometer might be accurate from 0" to 2", but carp from 2" to 4". Another unfixable problem is a bent frame due to dropping.

A short length of bright mild steel strip sawn into blocks makes a reasonable test set. Although BMS isn't particularly accurate, it's consistently the same size over short lengths, which is all that's needed to confirm micrometers get the same answer. If all three micrometers are in close agreement, hurrah! If they disagree with each other then at least two are duds, possibly all of them.

Does the accuracy of a micrometer matter? Good question.

If accuracy is actually important then buying an uncalibrated second-hand micrometer is daft. The build quality and original specification of the very best make was only valid when the item was new. Since then history has been at it. There's a huge difference between a little used carefully kept instrument and the same model, clapped out by heavy use, tossed into a toolbox and first applied as a G-Clamp in 1955. The proud owner doesn't know what he has unless the instrument is calibrated. And even then he's unlikely to use it at the correct temperature.

Fortunately most home workshops achieve fit by comparing rather than measuring. We rarely measure critical dimensions, email them to a friend, and expect him to make a fitting part by return. Instead, our other tools are compared with the micrometer and the actual dimension is almost irrelevant. Not necessary to know a shaft is precisely 0.7499" only that a bush bored to fit will slide on. A digital caliper works well as a comparator and old-fashioned spring calipers are remarkably effective too. Micrometers used as comparators don't need to be calibrated or in good condition. Nor do they need to be properly calibrated for most ordinary work like telling the difference between 10mm and ⅜" diameter brass rod.

If I were to mill a steel block to a random size in the range 24 to 25mm by 15 to 16mm by 9 to 10mm and ask a 100 members to measure it, I would expect hundreds of different answers! They'd all be nearly right, but scattered around the true value. Worse if the block were about 1250 mm long – too big for most instruments. I don't have any means of accurately measuring such a block myself, but we could all produce a close copy by comparison. Copying within 0.02mm (a thou) is fairly easy. Better than that gets exponentially more difficult, but it can be done. The pros probably wouldn't do it that way because trustworthy calibrated equipment gets the job done much faster and more reliably. If only high-end measuring was affordable…

Dave

old mart.