Hi Steve

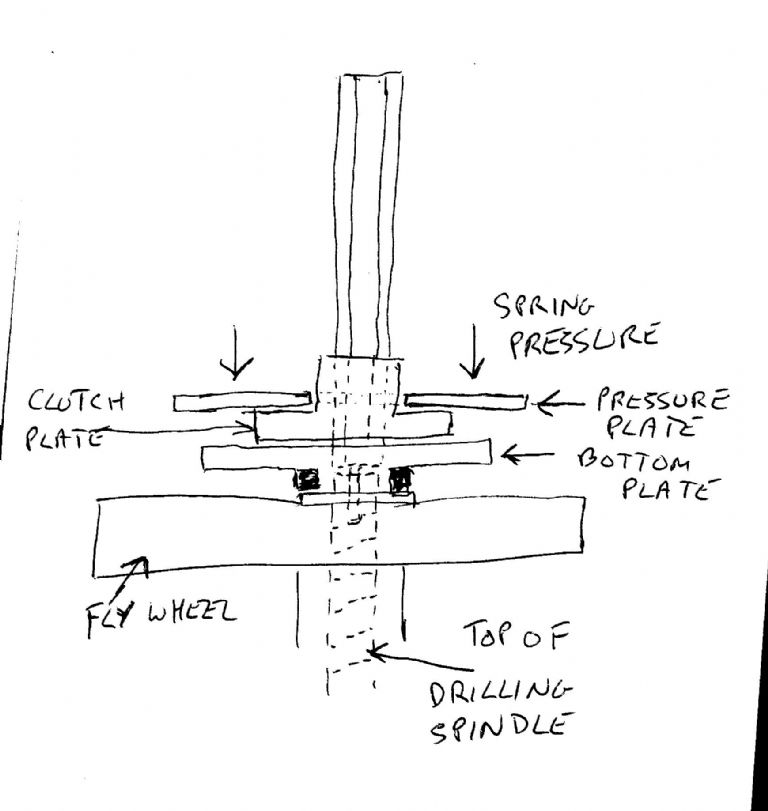

The pipe on which everything hangs is a peice of one inch water pipe. This machine ws designed to be shipped in bits and then assembled by the purchaser using whatever length of pipe he thought correct. So if you wanted it to drill something a metre long, all you have to do is change the peice of pipe.

It is designed to be used either as a bench drill or can be mounted on a post as many were.

There is no ratchet and pawl mechanism with this one and nothing is missing. The feed screw is a bit tight, as I said, I haven’t cleaned it up at all since purchase.

the paint is about %45 but there is very little rust on it. Most of the gunk you can see is saw dust. I have just finished building a bed for my daughter and quite a lot of the workshop is still delightfully coated in dust.

It does not autofeed. You turn the wheel with your right hand and adjust the feed wheel which is the round bit at the top. You get about 2 1/2 inches of feed.

The whole thing can be taken apart quite easily though you may have to send off to the nineteen century for a spanner to fit the bolt heads.

Yes, I am in Australia, Melbourne.

Cleaning it up would take about half a day and several days of waiting for the paint to dry at which time you will have a handsome and functional vintage post mounted drill.

Steve Wan.