George

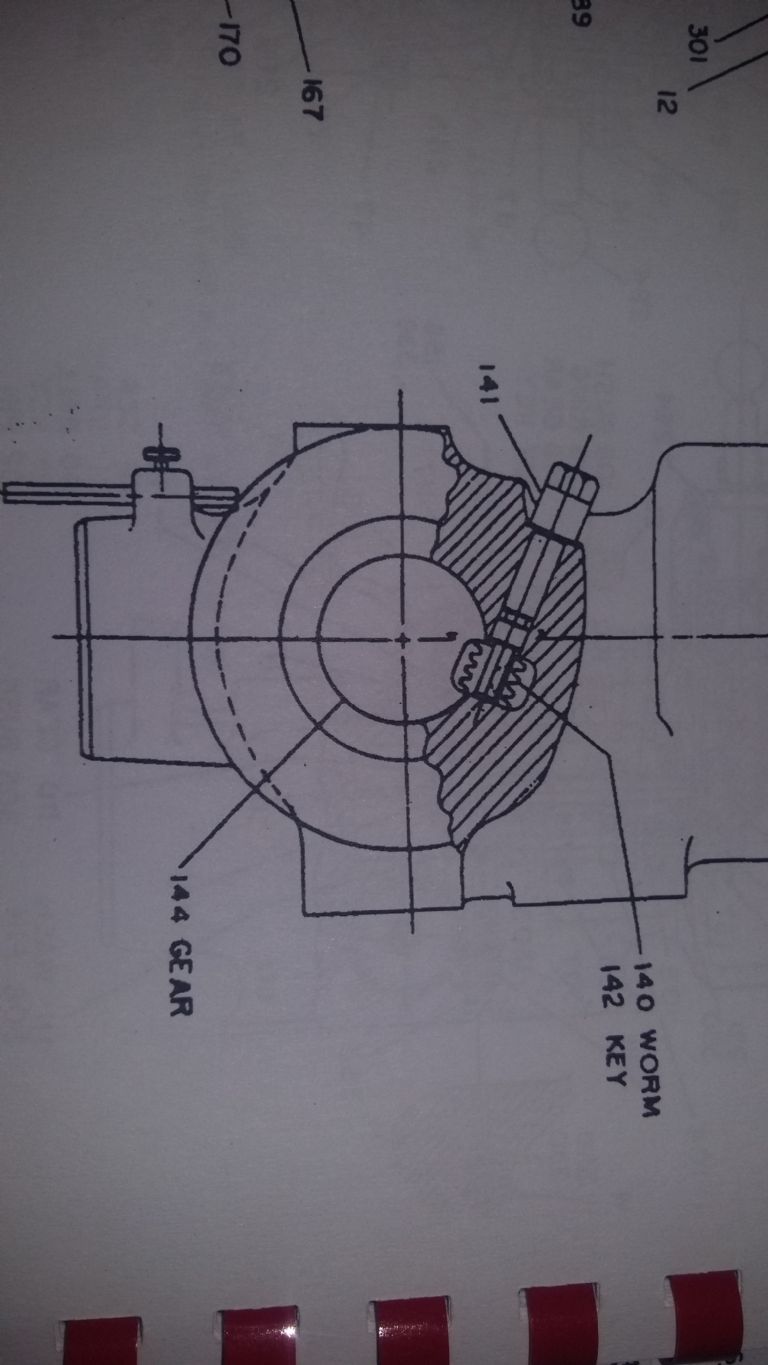

Glad the manual was of some use. Best to replace worm wheel and worm as a pair. In my, and many other folks, view that worm and wheel is seriously overloaded. Given how rarely most heads are rotated its surprising how many worms and wheels are in poor to dangerous shape. If I were doing serious work in that area I'd bore the hole for the worm carrier shaft right through and re-design the shaft assembly so the worm is supported on both sides. Mine is in decent enough condition but still doesn't give that nice warm "everything really under control" feeling when operated. Of course my 2J2 varispeed head is both weightier to start with and even more top heavy than the step pulley version you have.

I'l get back to you with an updated drawing on the feed screw with keyway positions included soon. Need to finish up a couple of shop re-arrangement jobs so I can get it out again!

Pretty much first reference I've ever seen to the Pick Feed Unit . It appears to have been part of a hydraulic Y axis drive device. Possibly for tracer or similar applications. Some discussion here :- **LINK** .

Link to Bridgeport patent for the device dated 1965 **LINK**. A quick skim thought suggest that it appears to adequately explain the basic operation of the device but not really clear as to actual use. Suggestions at the beginning are somewhat vague. Careful reading of the patent might provide you with enough information to get it working but judging by the Practical Machinist Forum link there is a fair bit of other gubbins needed to get it going. A brief mention at http://www.lathes.co.uk suggests that it adds automatic return and next cut application control to the Bridgeport hydraulic copying unit so it needs the rest of the hydraulic copier to function.

Clive.

Edited By Clive Foster on 19/12/2017 19:42:39

Clive Foster.