As promised last night.

The thermocouple was made from a suitable metal combination for the temperature to be measured. 1mm or 1.5mm diameter mineral insulated thermocouple cable would be used. The assembly would be as follows:

- Cut back the stainless steel cover of the MI cable

- Weld the two wires together to form a bead

- Attach the cable to the pipe by a stainless clip spot welded to the pipe

- Spot weld the bead to the surface of the pipe

- Cover the bead and end of MI cable with ceramic cement

- Cover the bead, end of MI cable and cement with a sheath of thin stainless steel sheet spot welded to the pipe.

Wrap the pipe including thermocouple with suitable insulation.

Other than melting ice was used for the cold junction I know nothing about the signal processing.

This whole assembly is fragile particular when the thermocouple wires are only about 0.005” to 0.010” in diameter. It was expected that some thermocouples would be lost before and during use.

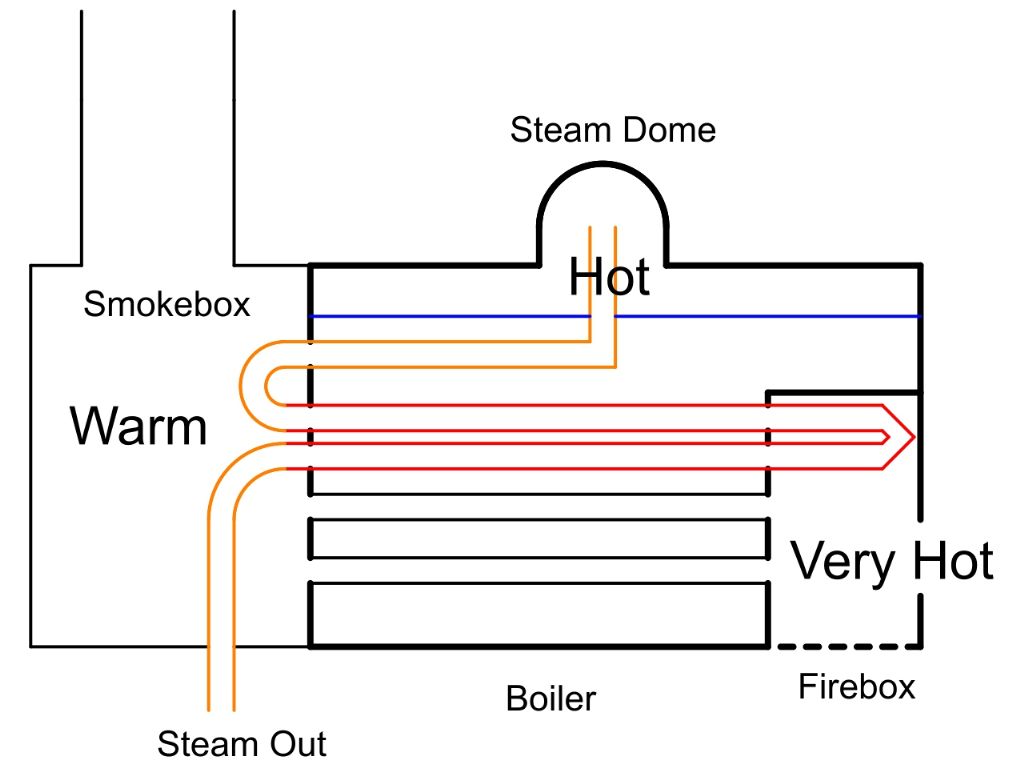

To gain an idea of the errors in the measurement the heat transfer to and from the bead needs to be understood. The temperature distribution from the flowing fluid to the outside air will be something like this:

With the corresponding heat flows:

Cvf Convention from hot moving fluid

Cnr Conduction across the wall of the pipe

Cna1 & Cna2 Conduction along the pipe

Cni Conduction through the cement, sheath and insulation

Cnw Conduction along the thermocouple wires

Cvo Convection from the outside of the insulation to the air

R Radiation from the outside of the insulation.

There are three heat balance equations:

Cvf = Cnr,

Cni = Cvo + R

Cnr + Cna2 ≈ Cna1 + Cnw + Cn1

The first two are trivial, the third shows us what is really happening. The conduction along the thermocouple leads can be minimised by attaching the cable to the pipe. The conduction along the pipe is difficult to get a hold on but Cna1 will be slightly less than Cna2. Therefore if the conduction through the insulation is reduced by increasing the insulation thickness a reduction in heat flow from the fluid to the bead follows and the bead temperature approaches the fluid temperature. Conversely if there is very little or no insulation the bead temperature will be considerably lower than the fluid temperature.

[Some of those still reading this post will say that the above is obvious, put insulation over the pipe and the pipe outside surface temperature approaches the fluid temperature. Yes, but a few postings suggested measuring the pipe temperature by a pyrometer and I can put numbers in the equations, do the sums and quantify the errors.]

The one difficulty with the above is the heat flow along the pipe. It is unknown but could be of significance. Because of this one should put thermocouples along the pipe. Given this and the need to have some redundancy for the couples that will fail you will have more thermocouples than pipe. Typical.

I have been careful to use the term fluid. The above can be used for gases and liquids. Because of the latent heat of evaporation of steam the thermocouple(s) can actually be calibrated in situ: If the boiler is held at a fixed known pressure and the heat to the boiler slowly increased there will be a long period when the pipe will be flowing wet steam. This steam temperature is known from the boiling point for that pressure and can be compared with the thermocouple temperature.

JA

Edited By JA on 08/02/2017 16:15:49

Hopper.