Some time ago I was commissioned to make this brass saddle tank, having gone through the usual steps of receiving drawings, deciding how I would make it, costing it all out, and preparing a quotation. So far so good. The inner and outer wraps were specified as 18g, whilst endplates were 16g. I planned to form the wraps by hand around ply formers and had it all nicely planned in my head. In the event the client bypassed my sources for some 'cheaper' 16g, to be used throughout, and so different methods were called for, not least the acquisition of second-hand industrial 3' rolls !

The first step was to buy necessary bar stock for a lift-off lid, and various fittings including threaded bushes and two removable strainers The lid was turned first ……

The lid was turned first ……

followed by the rest of the fittings …….

comprising threaded connectors for pipework, and twelve for 2BA fixing screws.

The first of the sheet metal parts to be made were the endplates, and in addition I used some 14g (sent in error) to make slightly smaller internal doublers, providing good location ledges for the wrap edges and a strong stepped joint.

The semicircular plates were bandsawed, endplates oversized, but doublers filed to the line. Eight fixing screw bushes were silver soldered into one endplate, and clearance holes provided in the doubler, then the two were soft-soldered together, as were those for the other end. .

.

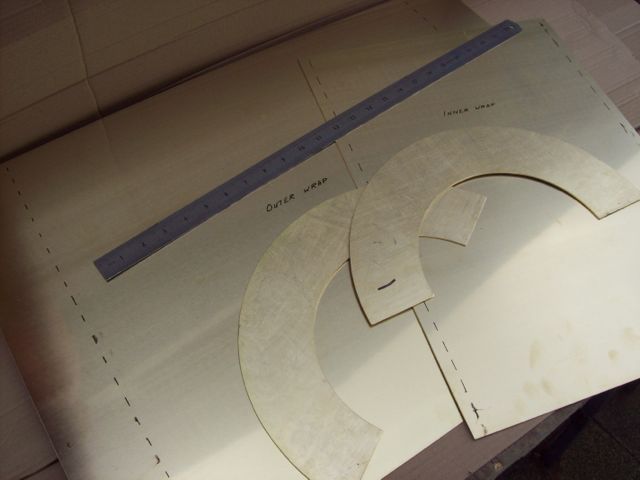

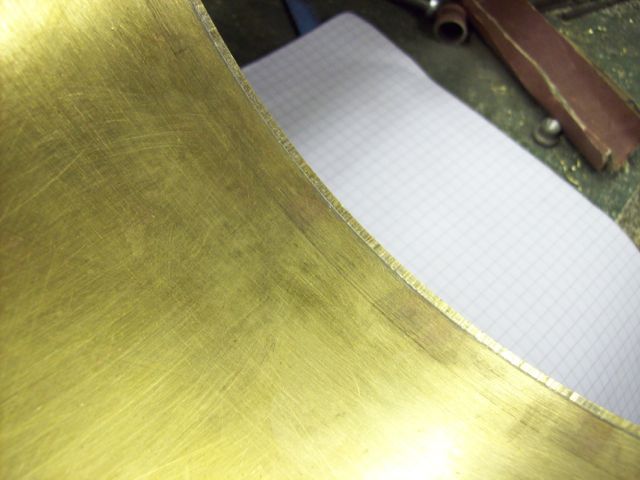

Following that, the inner and outer wraps were marked out and cut (sorry, those two pics are in reverse order) including longitudinal flanges on the inner one. Then I started playing with my newly acquired rolls and soon found that, despite their robust 3" rollers, the bending forces in the brass were sufficient to cause noticeable roll deflection, producing a less tight roll radius in the centre than at the ends. This resulted in a barrel shape and not art all what I wanted. The problem was overcome by wrapping newsprint in varying thcknesses along the roller length in compensation, and after a lot of trial, even more error, and over- and under-compensation, I finally had linear, circular wraps. These were mated with endplates and jigged for soldering.

Believe me, although no clamps are visible above, there were plenty in evidence before the gas flame was applied. In the event the soldering at this point went well.

Edited By JasonB on 12/03/2014 07:40:55

ken king, King Design.