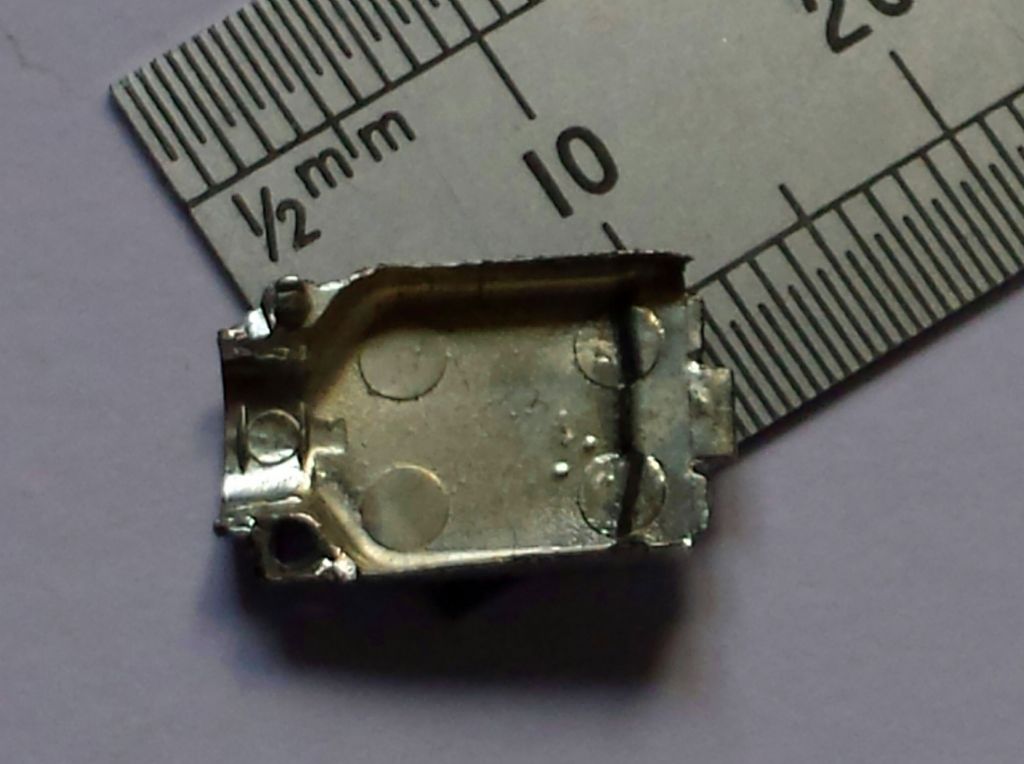

Not really an electrical connector but a Micro HDMI plug on the end of a lead for 'camera to monitor' cable. (Its about the same size as a micro USB on a phone)

The cable is supplied with moulded on plugs and I cut off the outer moulding to investigate shortening the connector because with the camera mounted in its special housing there was insufficient room for this straight plug.

Other connectors of this type usually have a sheet metal folded cover, this one though has two small diecast parts forming a clamshell arrangement. What surprised me though was that the two halves had been soft soldered together, The diecast metal had a whiter than usual appearance so I initially thought it might be tin plated.

The biggest surprise though is that whilst it is plated (layer of copper underneath) the base metal itself solders as easily with 60/40 as any normal electronic component!

In the bottom picture you can see where I have filed away a small area then heated it with soldering iron, the solder wetted the surface instantly.

Any ideas what the metal might be?

Just out of interest, the cable wired to this 20 way connector has 6 twisted wire pairs each individually screened, plus a couple of single wires, and all in a diameter of 2.2mm!

Ian P

Russell Eberhardt.

Russell Eberhardt.

Its great advantage is that it is ridiculously CHEAP!

Its great advantage is that it is ridiculously CHEAP!