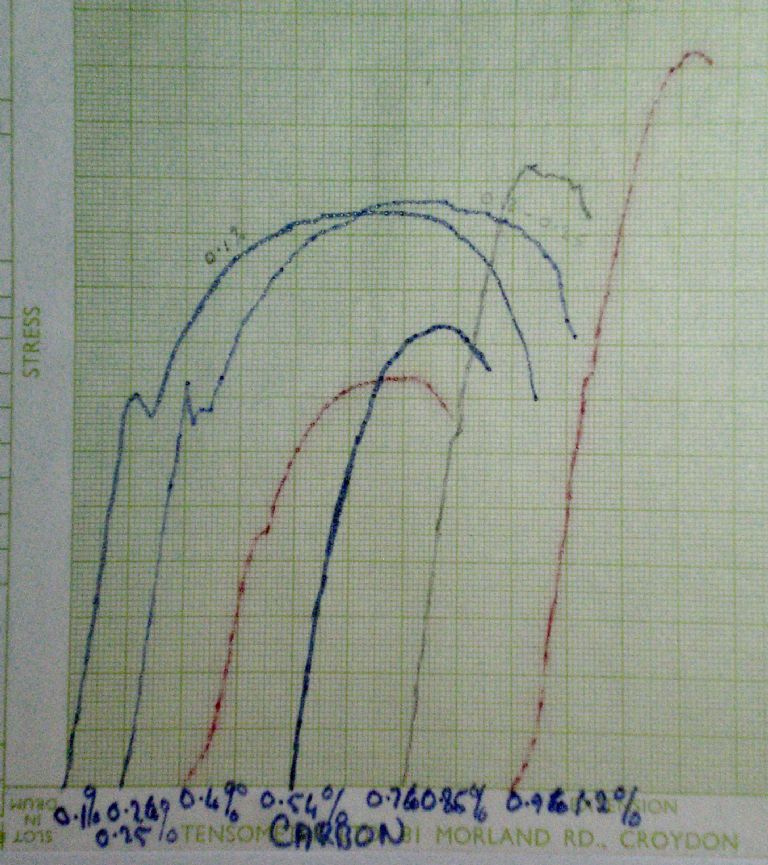

Hi, just another extract from my college days, which should help understand this streching business, and will back up what mgj is saying somewhat. First is a tensometer graph which I did in my lab work, it shows different carbon content steels streched to breaking point. Stress is shown on the vertical and extension is shown on the horizontal. It can be seen that the higher carbon content steels do extend more before the yield point, allbeit by just a small amount.

Proof Stress

Mild and medium carbon steels have a definite yield point, followed immidiatly by a plastic stage, during which the material extends considerably. As the carbon content increases, this plastic stage becomes smaller and the steel enters the ductile stage soon after the yield point. In very high carbon steels both the yield point and the plastic stage disappear, and as the stress in the steel is increased it passes directly from the elastic state into the ductile state.

In materials which have a yield point, it is important that the yield stress is known, for if this stress is exceeded, then parts made of the material will have large permanant extensions. This permanant set is often specified at 0.1%, i.e. one thousandth of a gauge length. Thus on a 2″ gauge length, the permanant set would be

2″ X 1 over 1000 = 0.002″

The stress providing this permanant deformation is discribed as

Proof Stress

Hope this is of interest to someone.

Regards Nick.