Comparing Loctite 638 and 603 is made unnecessarily difficult by the slightly different formats and contents of the TDS data sheets. How hard would it be for Loctite to use a common format and provide sensible explanations of how to decide which to use when. Methinks ulterior motives for the "superficially same but actually different" style used.

Anyway 638 TDS gives Compressive Shear Strength between same material pins and collars of 4,200 psi for steel and 2,700 psi for aluminium. Pretty much in line with the graph although that actually implies about 2,500 psi by my maths.

603 TDS doesn't give all that information but it does give 3,260 psi for steel pins and collars. Graphs on the one I downloaded imply that bond for aluminium gets up to around 75% of that for steel viz :- 2445 psi.

So its pretty much a wash after a week.

Have to assume that Compressive Shear Strength is actually a meaningful parameter for behaviour out in the real world. I think I can see how its a reliable and reasonably easily measurable test parameter but what it adds up to in the real world I know not. Can do the maths but it still doesn't mean much. Torque on a specified size bar in a specified hole would be so much easier for ordinary folk. We've all sheared bolts in the past so have some sort of feel.

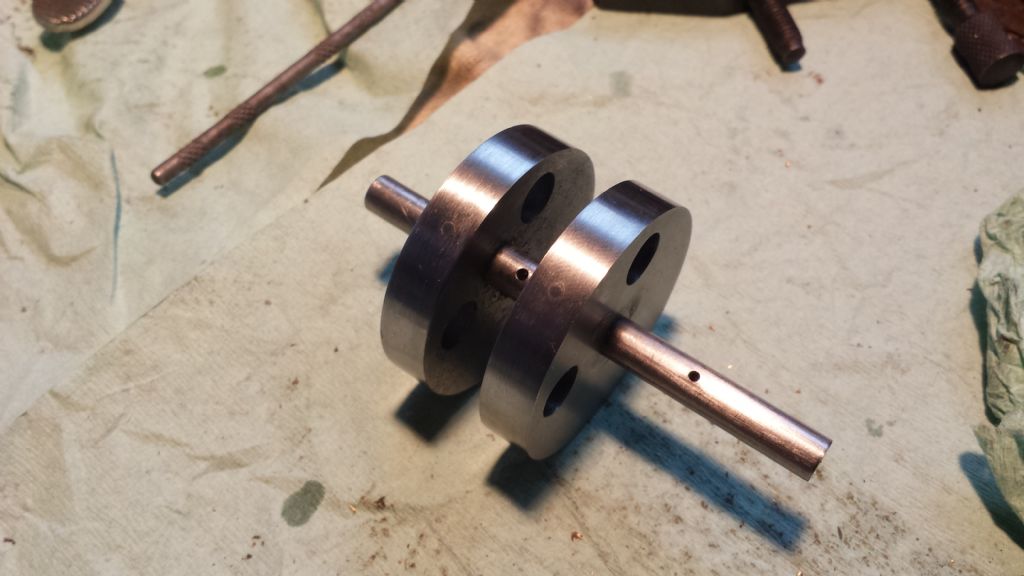

One really annoying thing about Loctite (and other suppliers of similar nostrums) is that its not made clear how quickly headline performance drops off if you don't do things exactly right. Reading between the lines of several less than satisfactory conversations with Loctite tech reps I'd hazard a guess that most casual users are working around the 1,500 psi region even with the uber strong stuff. Still quite a lot as a 1" shaft in a 1" deep hole is "pi" square inches. Implies something over 4,500 lb to push it out even at 1,500 psi if you have full coverage. But it isn't that simple on a real component.

Clive.

Edited By Clive Foster on 13/10/2017 18:04:27

Edited By Clive Foster on 13/10/2017 18:22:55

Robin Graham.