Small modeling lathe

Small modeling lathe

- This topic has 19 replies, 11 voices, and was last updated 8 July 2019 at 14:34 by

Neil Wyatt.

Neil Wyatt.

Viewing 20 posts - 1 through 20 (of 20 total)

Viewing 20 posts - 1 through 20 (of 20 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Is Green Hammerite really so ‘infra dig ‘ ?

- Octopus … Is there method in this madness ?

- TurboCAD Snaps and Dimensioning?

- Pulley taper – Herbert B drill

- Vee micrometer

- Amadeal AMABL210E Review – Any Requests?

- TuffSaws?

- Woodward/Wilding Gearless clock

- Mardrive component Misplaced motor component

- Readability / clarity in new combined magazine

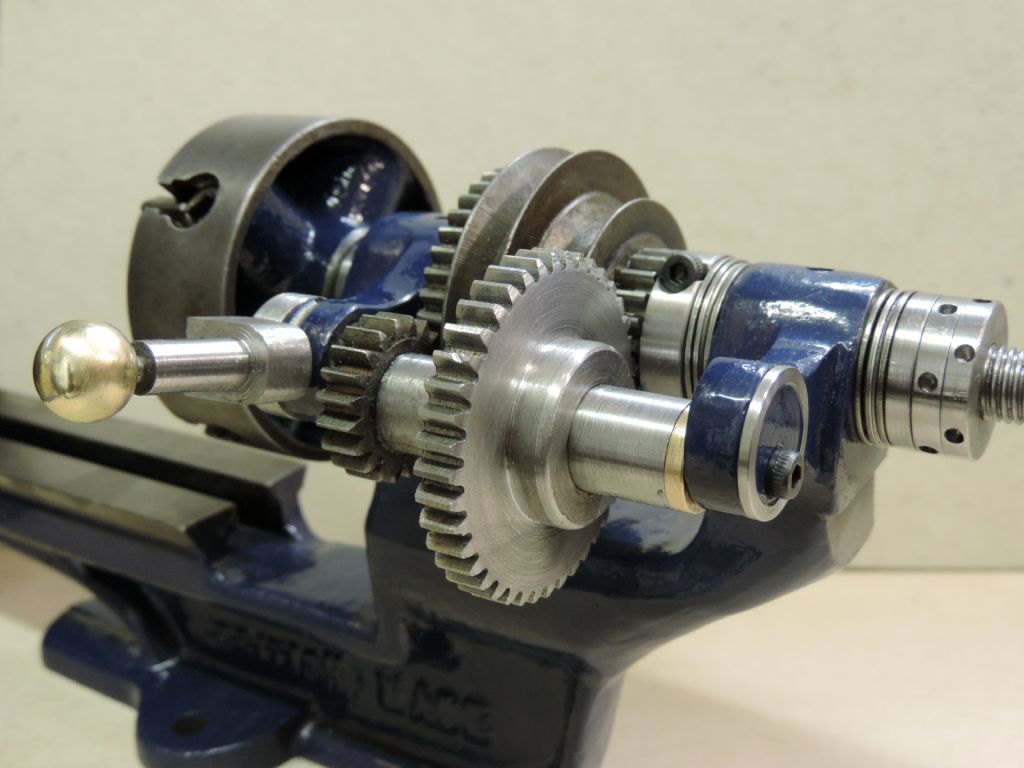

![wp_20190418_004[1].jpg wp_20190418_004[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829240.jpg)