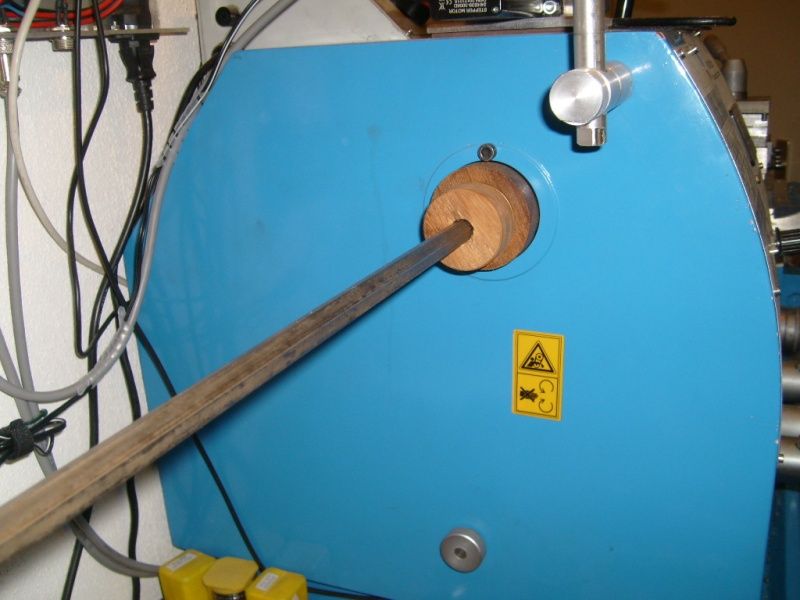

I too went for solid bushes bored to size to support bars hanging out of the spindle.

But mine is a bit more high tech.

A clear out in the plumbing department shortly after doing a batch of long overhang jobs unearthed a brass internally flanged nut whose bore was a little bigger than that of the 1024 spindle. As the S&B 1024 has a native 5C collet fitting spindle nose and I have full sets of 5C in both metric and imperial my habit is to use the collets for slender materials. I made an adapter to go on the hand wheel of my collet drawbar to take standardised nylon or delrin bushes made as needed. Black for imperial, white for metric.

Having made the beast after that batch of slender jobs convinced me that simply shoving a wadded up rag in the end was a bit too bodgy it sees very little use. I just don't seem to get jobs needing lots of slim parts these days so cut first, turn next is fine.

I think the suggestion of using ER collets made by DC31k is probably our gold standard for this sort of thing given that folk like us are generally concerned with relatively modest stick out.

The dangers of single point support where long bars are concerned are well known in industrial practice. There are rules of thumb for manual machines a relatively low speeds. Factory set ups with fast running CNC, Swiss or hard worked capstans tend to be sorted a but more seriously

Clive

Edited By Clive Foster on 07/10/2022 14:07:04

Clive Foster.