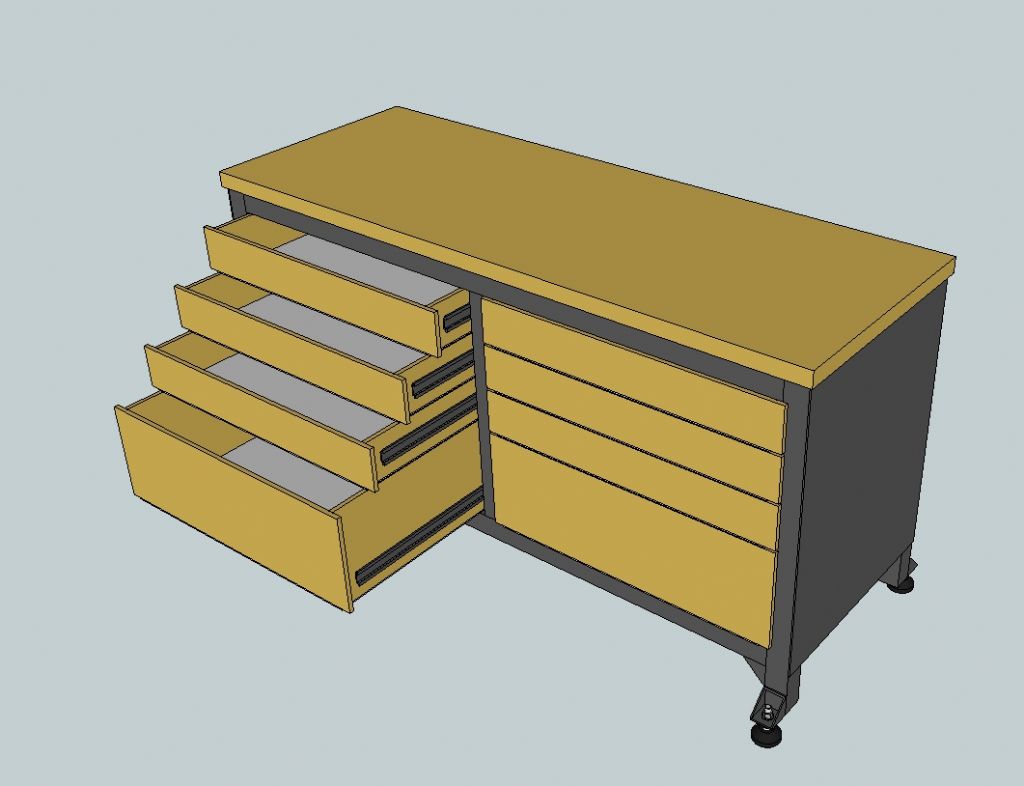

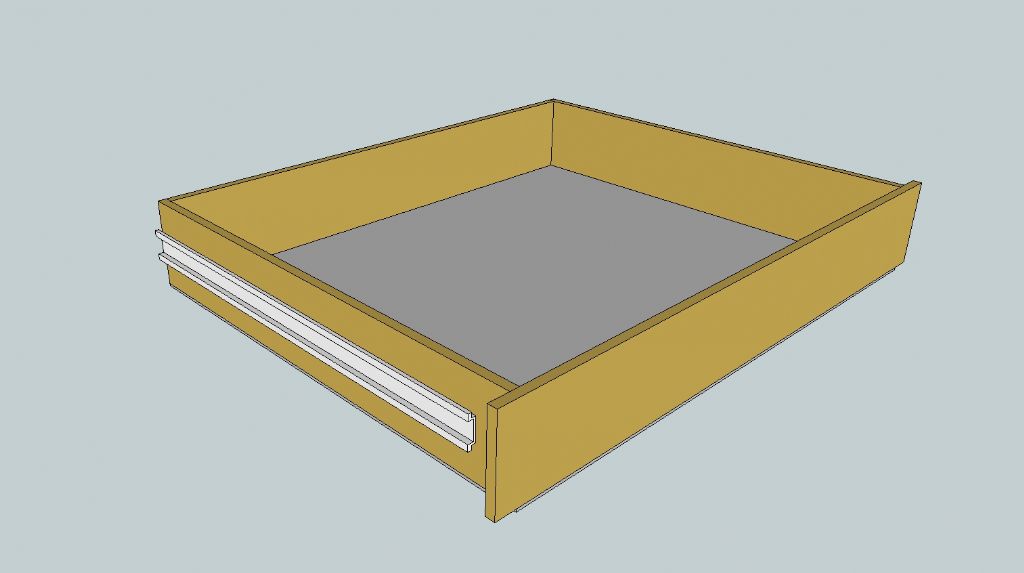

For workshop purposes you should always use full extension, full load, runners so the whole of the drawer is directly accessible. Many of the kitchen drawer kits are only partial extension so you need to fiddle stuff at the back out past what's in front or even partially unload the drawer first. That gets old real fast. Even those with full extension runners may not have full load capacity at full extension. Need to distribute things to keep the weight towards the back. Specifications also assume the load is evenly distributed. Plonking a small rotary table or decent size chuck in the front corner many be more than the structure or runners can cope with.

If you plan to store larger, heavier items such as chucks, faceplates rotary tables or vices et al consider making the relevant drawers open side with only a minimal lip for the runners. Easier to get a good grip without the sides in the way. Less lift needed to clear the sides too which can also help handling. Often worth packing up the bottom so as to give a straight slide off with no lift. Pretty much mandatory to do this with the common horizontal / vertical rotary table as the handle and dial assembly projects below the base so you either have to lift the base or cut a slot. Slot is not a good idea in practice! Tried it and rapidly re-engieered to pack up the base.

If one side of the cabinet is going to be up against a wall carefully consider what is going in that last bay as loading and unloading will have to be done semi-sideways with no elbow room on the wall side. Good place for sideless drawers or plates of holes for things like drill chucks, collets, et al.

Clive.

Joseph Noci 1.