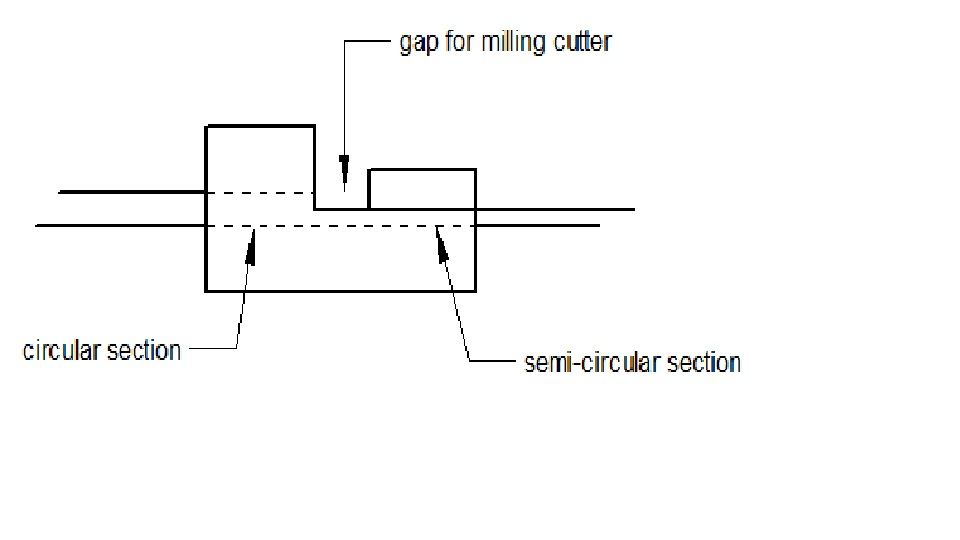

Jig for milling Half Round Beading from round stock

Jig for milling Half Round Beading from round stock

- This topic has 32 replies, 14 voices, and was last updated 2 February 2016 at 20:07 by

Steve Addy.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Boiler Design – issue 4765

- Lathe index tips

- Adding a quill lock to a drill press

- Amadeal lathes – Any good??

- Pipe bending by hand versus pipe bending tools

- Hopeless…Alibre Ass

- My vise isn’t at 90 degrees

- John Robey : Horological Articles downloadable

- Model Engineer Magazine Collection

- Round Bar Bender