Posted by Raymond Anderson on 24/01/2016 18:35:05:

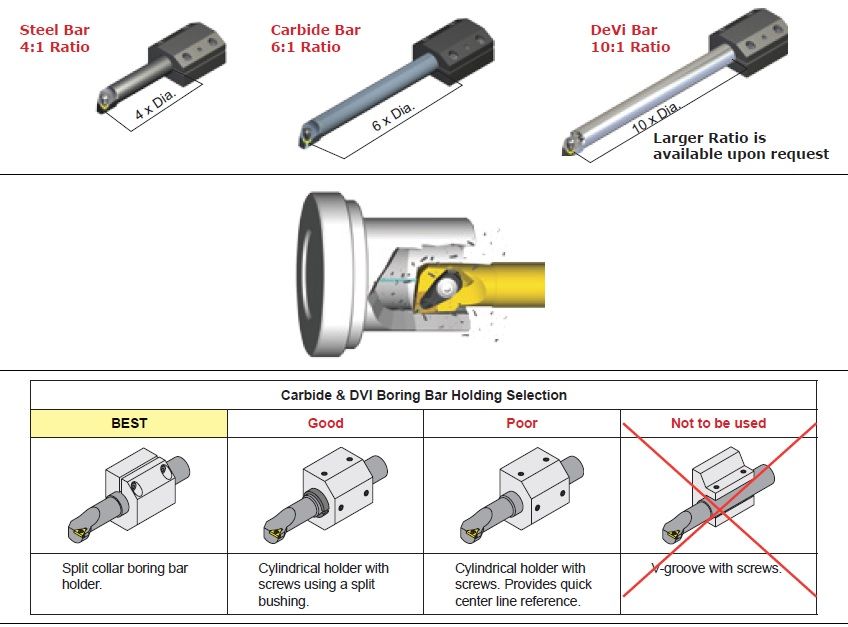

Hi Muzzer, On the basis that me brother [who is a foreman turner ] pointed it out to me, and I think he knows a bit more about it than me.  Re, the flats on Carbide bars,. I cant answer that, but Sandvik ,Walter,. Arno, et al, all say NO screws should bear directly on a "CARBIDE " bar and prior to knowing about that I broke a Carbide bar by having the screws directly on the bar [ broke right at the middle screw ] That was an expensive lesson that I have no intention of repeating. A lathe is no different from a milling machine in respect of Rigidity, the more the better. If you were to try the normal style over the sleeve / toolblock style then you would see the difference. [It would probably make no difference to what most of us make ] but the difference is apparent.

Re, the flats on Carbide bars,. I cant answer that, but Sandvik ,Walter,. Arno, et al, all say NO screws should bear directly on a "CARBIDE " bar and prior to knowing about that I broke a Carbide bar by having the screws directly on the bar [ broke right at the middle screw ] That was an expensive lesson that I have no intention of repeating. A lathe is no different from a milling machine in respect of Rigidity, the more the better. If you were to try the normal style over the sleeve / toolblock style then you would see the difference. [It would probably make no difference to what most of us make ] but the difference is apparent.

That's funny. When I look at the brochure for the carbide shank boring bars I bought recently, the sleeves they sell for them have grub screws to hold the bar in place. Perhaps your brother should write to them to tell them where they are going wrong? When he's at it, he should also get in touch with Simtek who also don't seem to know what they are doing.

If it really is necessary to avoid contact with the set screw, I would use a "packing piece". I often do this if I'm concerned about damaging the top of the tool. Much less palaver than making up a vast system of sleeves and holders?

Merry

Raymond Anderson.