I've made a few batches of pipe unions for a steam railway where I do volunteer machining. Mostly these are for lubricator distribution systems and airpumps. The 60 degree included cone and seat make sense, but I've found a number of different standards in use, sometimes on the same loco – there are 90 degree, 30 degree and flat-faced 'top hats' as well. Lots of the locos have had multiple operators, often in different countries, and very long histories of repairs and modifications. It's difficult to depart from what you're given to duplicate, because you don't always know the risks you might incur by making the assembly longer or shorter, so attempts to standardise or simplify tend to be sporadic and incomplete.

It does seem to make sense to reduce the cone included taper 1 degree less than the seat, and take the cone just short of a feather-edge to the centre bore – the seat then compresses the cone as the nut's tightened, for a good seal. 30 degrees inc. and a 29 degree cone works best where there's room. LG2 also has a bit more maleability than CZ121 brass.

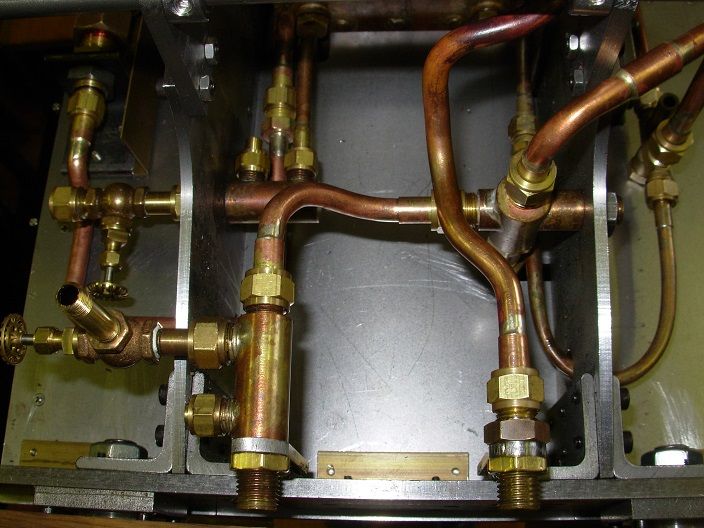

Your pipework's a helluva lot nicer than some of it on the railway  – but then they get to cover a lot of it with casings so passengers and bystanders don't see it.

– but then they get to cover a lot of it with casings so passengers and bystanders don't see it.

Edited By Mick B1 on 09/05/2018 20:51:47

David Wasson.