Hi guys

I thought I would update on this, and hopefully save you some drinking time.

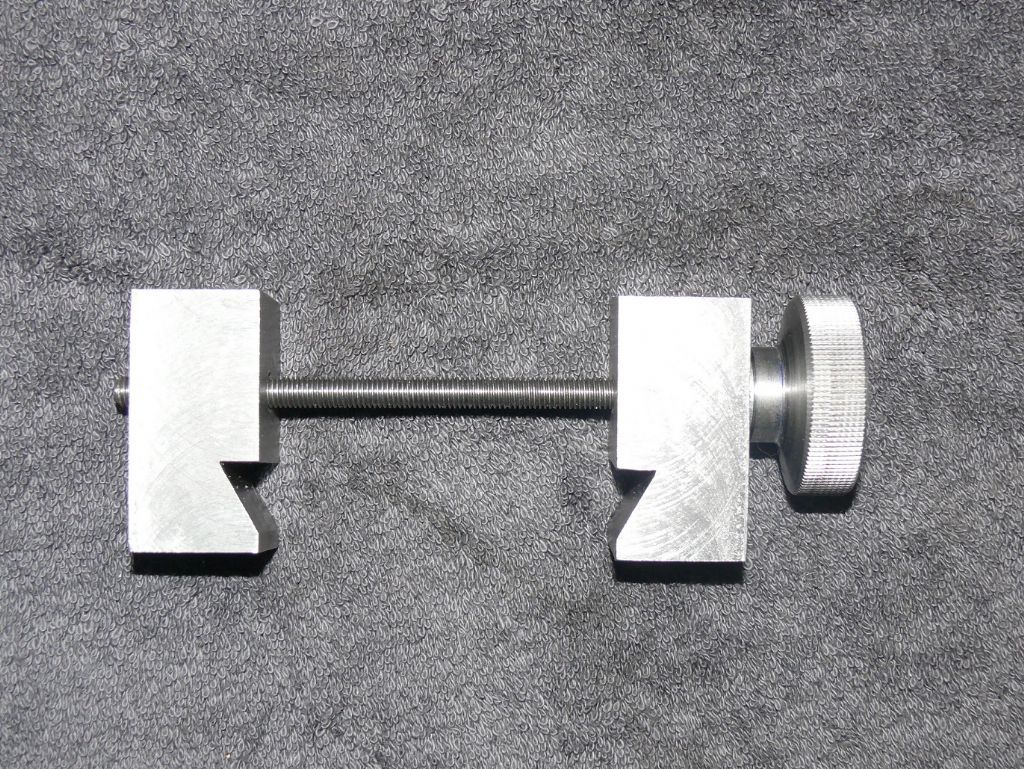

So, the clamp thing (in my opinion) waste of time. The Plastic printing guy (eBay – great guy and knows his stuff) doesn't think it will work but did provide an option with magnets BUT with his clock embedded.

Im not keen on a 30mm clock or buying another when I have a few old ones around.

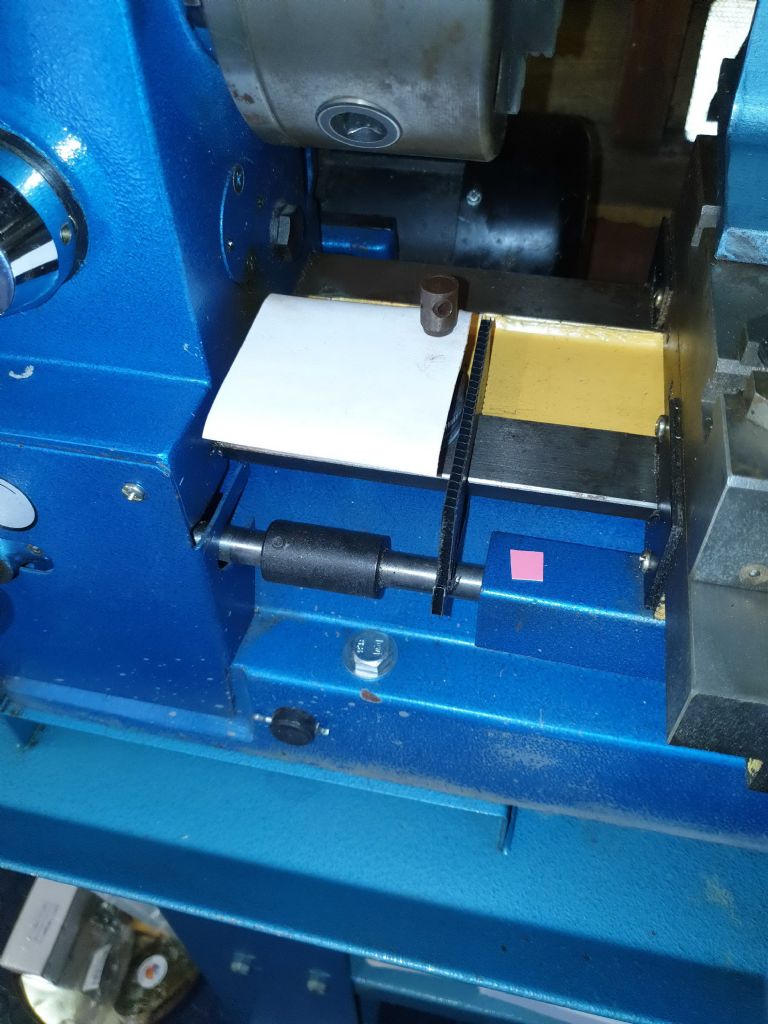

Got me thinking about using a >100mm digital vernier instead of 50mm clock at silly money.

If I have to use magnets, then I can prob make myself easy – right?

Turns out YES. There's a YouTube clip somewhere of a US guy making one with iGaging depth gauge. Can buy in UK for >£50 but Amazon £40 imported from US.

So for magnets.

I did loads of research using couple of magnet sites. Nothing perfect.

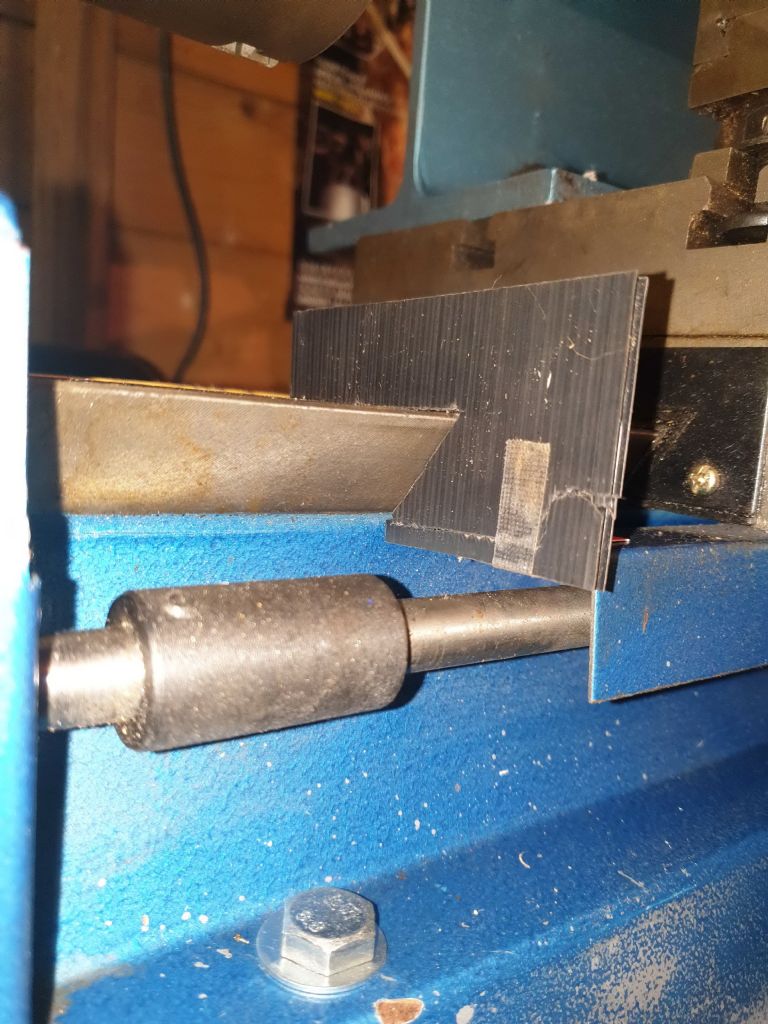

Then, I went back on Amazon and found these (below) because they have a hole which I can attached to Saddle (Oil Guard thingymabob) and I hoped the vernier marking wheel would be sufficient for pulling the gauge. It does perfect.

Magnetpro 8 Pieces Strong Neodymium Rectangular Magnets 20 KG Force 40 x 13.5 x 5 mm with Countersunk Hole and Capsule, Household and Industrial Rare Earth Magnet with Mounting Screws

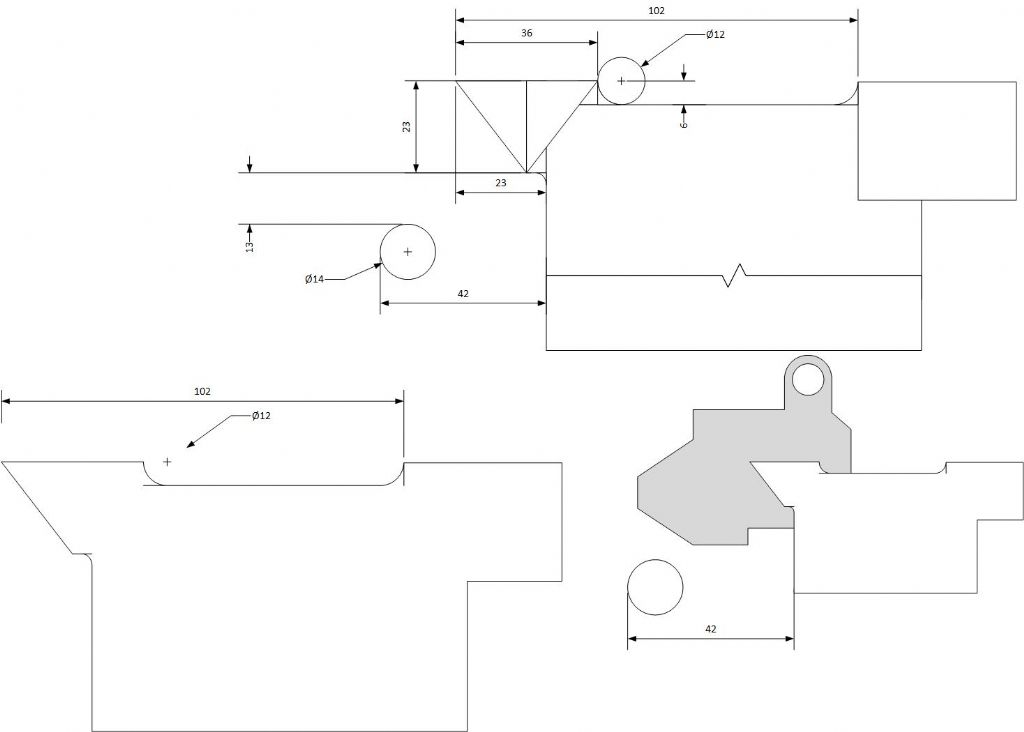

Also, I thought the 5mm height and 40mm length would be OK for under a base-plate: which is a 70mm piece of 40mm angle iron (maybe with some 5mm packing also to avoid any snatching when installing). Note that I'm using 5mm drills in pic for testing the height.

Sorry I haven't fitted these yet so cant show a finished pic.

Sorry I haven't fitted these yet so cant show a finished pic.

Turns out I didnt need these specific (8 pack) magnets, but thought I would share that they are very good, so I'm sure I'll find a use for them – one day! I could have bought just 1 of something similar for under the base-plate. With hindsight I would get 1 magnet of similar quality and 5mm height, which is good height for hitting metal on the Saddle oil-guard.

Anyway,

I also found this magnet: Magnetpro 8 Pieces Strong Neodymium Rectangular Magnets 20 KG Force 40 x 13.5 x 5 mm with Countersunk Hole and Capsule, Household and Industrial Rare Earth Magnet with Mounting Screws

Turns out this has an M3 screw. But would this small thing really be strong enough?

Yep. Ive just tried it with steel ruler on my desk and it sticks like shit to a shovel. So, turns out adding an iGaging vernier is a piece of cake.

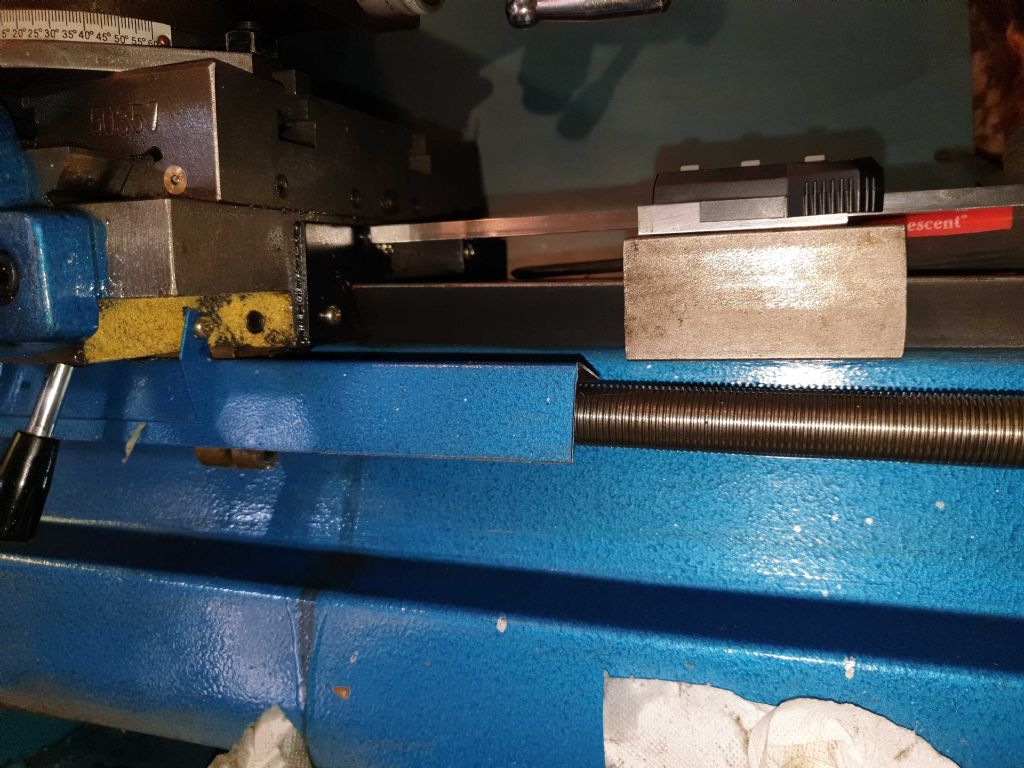

BUT as with all things with this Clarke lathe, its not all good news as it's going to be in the way of the Tailstock.

cheers all

Coming soon – How to make a Gin Still out of a Clarke CL500M

Howard Lewis.