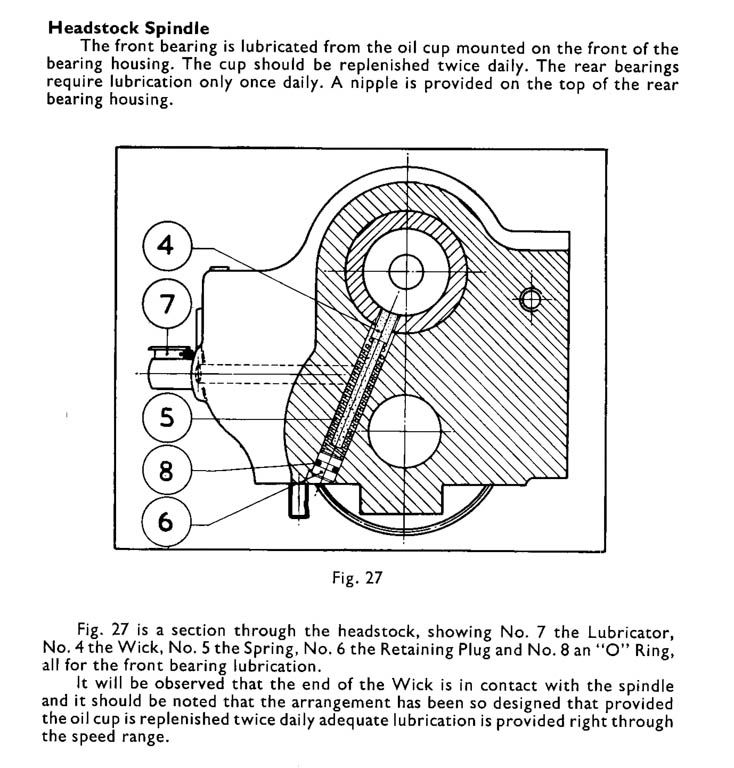

I was concerned that the oil consumption of the front headstock bearing of my lathe was negligible and certainly would not require topping up twice per day however much I used the lathe. I removed the spindle and took out the felt wick which was in perfect condition when compared with the new one I had purchased. The spindle was also in perfect condition and the bronze bearing still had most of the original scraping marks present. Absolutely miniscule wear (if any) after many years of use.

I put the new wick in (after soaking it in oil for a few hours) pushed it down and secured it temporarily with a large dress making pin to ensure the spindle cleared the end of the wick whilst assembling it. I carefully assembled the spindle and set up the bearing s as described in the Myford hand book – twice as I am ashamed to say the first time I forgot to put the belt back!

The bearing still only uses a minimal quantity of oil which I guess is correct as the compressed felt that the wick is made from clearly does not transmit oil readily. This is probably why Myford chose this method of lubrication control as opposed to the uncontrolled total loss system of the old ML7.

I use Three-in One in my head stock as it is a high quality thin lubricating oil. If any one wants to buy 32 grade hydraulic oil ( =Nutto H32) try your local garden machinery repair company, The one near me has a bulk tank and supplies it at a very reasonable price when you take along a suitable container. Myford charge the earth for a straight forward grade 32 hydraulic oil.

Lambton.