Hi Ed,

We have to agree with Jeff that p.acetal is `almost impossible’ to glue or paint. I would add `successfully’.

This applies to various crystalline materials (polymers) such as polypropylene, polyethylene, nylon, polyacetal, etc.

That said, there are situations where these very materials are regularly painted. For example, automotive bumper bars injection moulded in polypropylene are etch-primed before given a top coat.

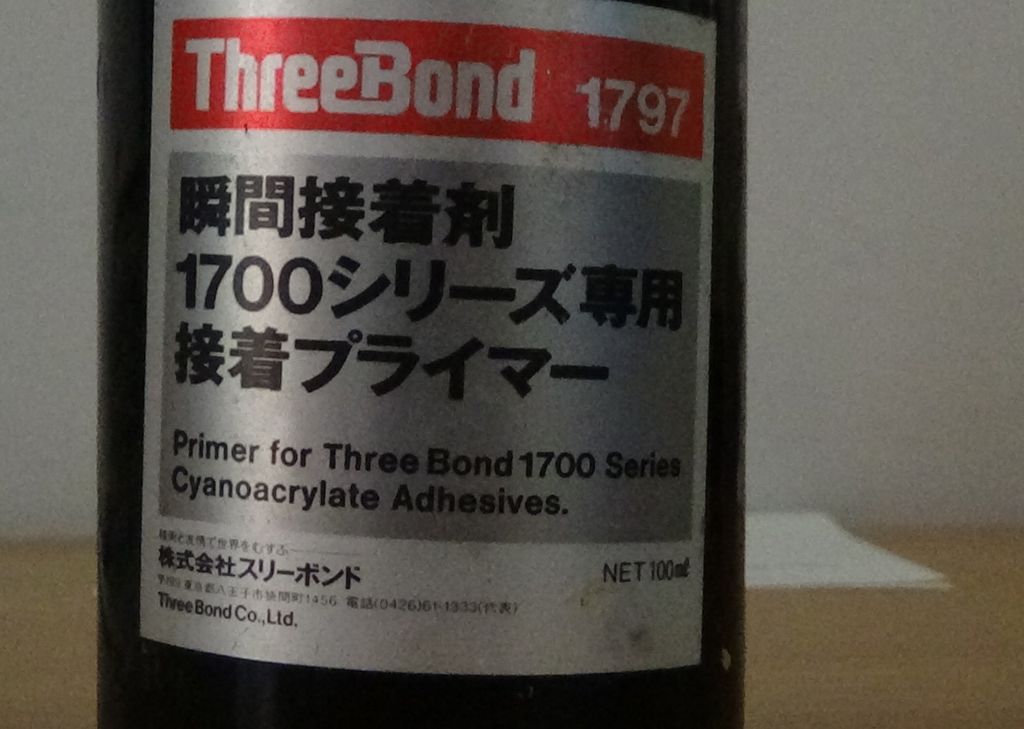

I’m unclear about p.acetal but I have in the past used an oxidising primer called ThreeBond 1797. (See photograph and link below.)

The label shows it to be for cyanoacrylate adhesives, and I’ve used it to prime polypropylene with some success. The bottle holds 100ml, but how much it cost I can’t recall.

**LINK**

Of the amorphous plastics (polymers) which can be glued with less difficulty, rigid PVC, and ABS should be fine, keeping in mind that ABS can exhibit a lower value of friction.

On balance, p.acetal would be my choice since it machines easily; will hold its shape quite well (i.e. low creep); correctly primed, it can be glued.

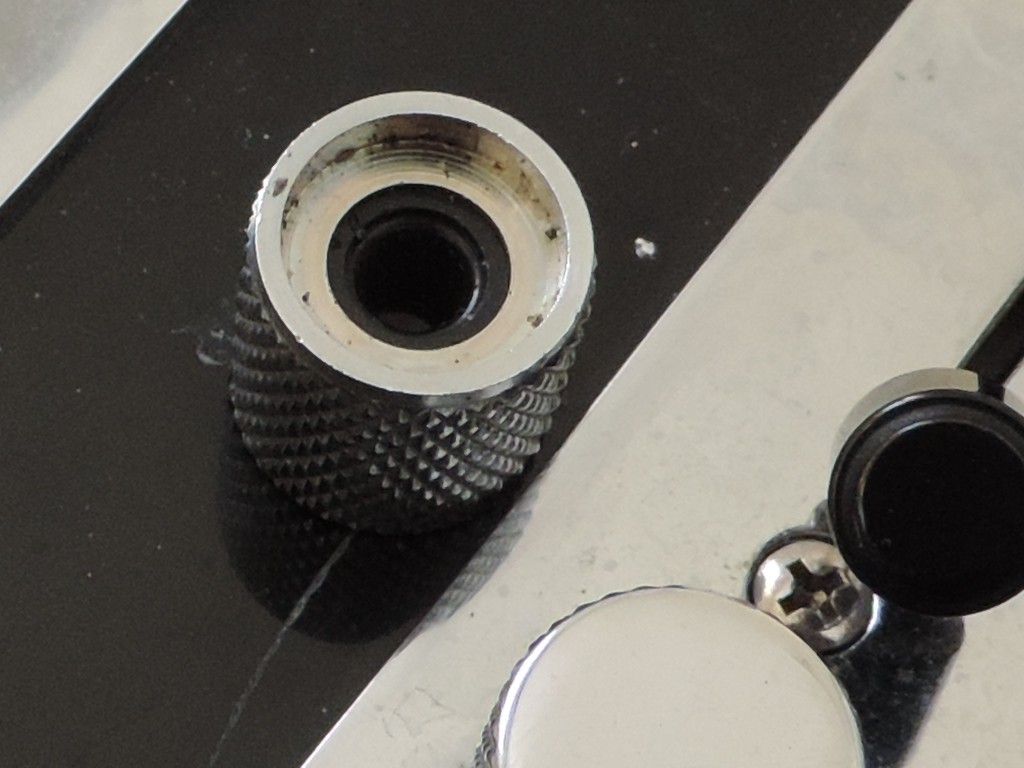

I would however, be tempted to introduce grooves into the OD. These would be of the spline type to resist torque, and circular grooves to resist pull-out.

Polyacetal is however, used for bearings and is rather slippery. Since the task seems critical, maybe you should do a few tests before attending to the real thing.

On a final note (or two), acrylics and polycarbonate (and others especially amorphous polymers) are prone to ESC (environmental stress cracking) so watch out for chemical agents which can introduce this hazard.

I’m also very conscious of the notch sensitivity of materials. Far too many parts fail due to notching (lack of radiusing. Good luck!

Regards,

Sam (aka Dennis)

Edited By Sam Stones on 04/05/2016 01:31:14

Ed Duffner.