What an interesting Christmas. And I partly mean that in the terms of the Chinese curse (May you have an interesting life).

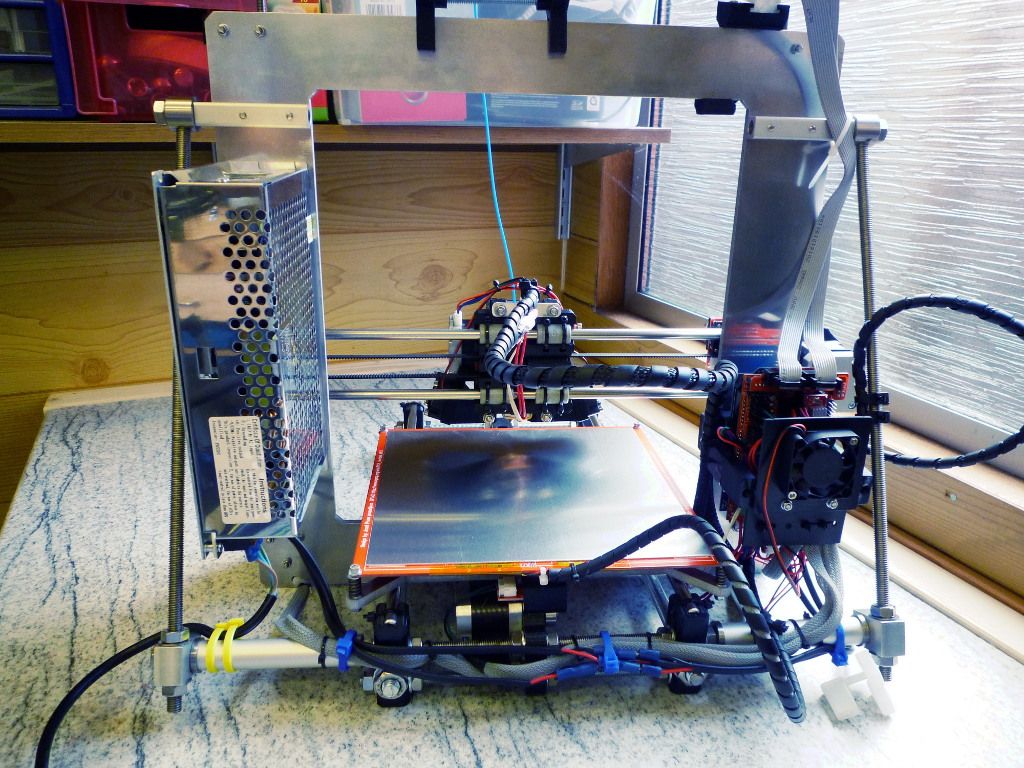

Building the Factory 3D printer was quite challenging. Actually it's not particularly hard – If you have no more than two thumbs and half a brain you can do it. But it's a sensitive thing.

In my case I got it working on Boxing day and printed some of my own designs (toothbrush holders are useful despite the jeers of at least one of the forum members!).

Then it all fell apart. I wanted to print a green lizard soap dish for the shower (I know it's not exactly Brunell is it?). I changed the filament for a green on (who has black lizards, eh?). And it just stopped working. The board decided that the hot end was at 83 degrees and the bed at 65. regardless of if there was power to heater or even if the thermistor was connected.

Mike (Mr Factory 3D) sent me a replacement board by return (plus some spares – I would recommend a spare hot end, barrels and nozzles).

Got that, the temperature now read correctly (phew!).

But now the models go mad. The head suddenly jumps to the wrong place and, worse, the extruder runs backwards effectively jamming the hot end which is a bloody nuisance to sort out.

More help from Mike. Tune up the current in the motor drivers. Realise that you've mucked up the bed alignment so recalibrate.

Print one of the many models which have been misbehaving. It works.

Print one of mine. That works too.

Now print a big one. Well, the Jury's out. mainly because it's a 5 hour print and only 2 hours in. But its working.

A few take away's if you get this kit.

For me the main thing is that Mike's support is above and beyond the call of duty. If I'd bought this kit from China it would just never have got working. Well with a LOT more stress, perhaps. If you do decide you want a 3D printer, make sure it's either got some good support behind it or it's not your first.

Secondly, you really need to be very anal about the instructions and if something changes pretty much go back to the start and work your way through.

Thirdly, with this kit, the wiring connections seem to be sensitive. the motor plug and the board socket are different sorts. I will be replacing the motor plugs with the same sort as on the board when I can.

Lastly, it would seem that once it is going, it's going.

I would still recommend this as a build despite the challenges and extra time it's taken me to get it going.

And I'm now making a toothbrush holder for my wife. Which actually has the potential to gain me brownie points – much needed after a Christmas not entirely focused on her!

Iain

Neil Wyatt.

Neil Wyatt.