After doing the ELS on the 14D, I finally re-started on a project that began more than 15 years ago – A Spot Welder…

re-started as I finally need such a capability to make some simple galvanized sheet metal 'boxes' that are to be covers for the plastic box that house the electronics for our Wildlife Animal tracking logger, spread around in the Namib desert and scrub – the metal cover protects against the wild sandstorms and as it is spaced away from the plastic box beneath, provides some protection against the hot desert sun…Anyway…

The first plan was to use an 800VA toroid that I had, wound with 3 x 5 turns of 8.5mm diameter copper wire – about 50mm square in total. This worked, gave 1800amps, but the secondary wire still got hot as hades after 10 x2second welds.

The three 8.5mm diameter cables

So scrapped that odea and found an old 150amp Buzz-Box Welder. Stripped the core down and re-assembled so that it was a plain C-Core shape, and then added my windings.

Primary tapped for 220V, 230V, 240V, wound with 3mm diameter Cu wire.

Secondary 2X4 turns of 95sq mm cable wired in parallel – 190sq mm in total…

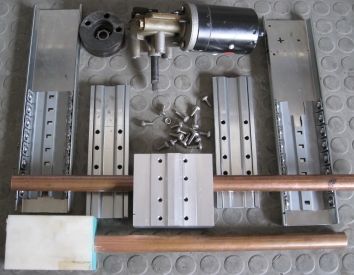

Then started on the vertical slide mechanism for the pincers – used a heavy duty drawer slide, cut to suit:

Feed arms are 22mm diameter solid Cu bar.

First concept was to use a wiper motor with an over-center toggle to drive the upper pincer up and down.

Over center toggle:

Was not happy with that idea – makes it difficult to change pincer stroke and pinch position..

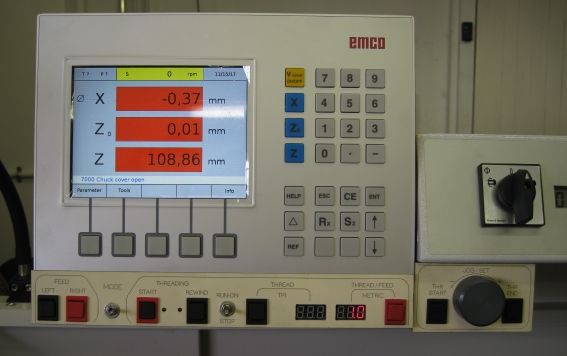

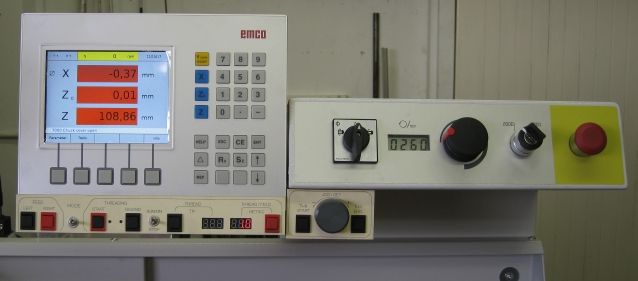

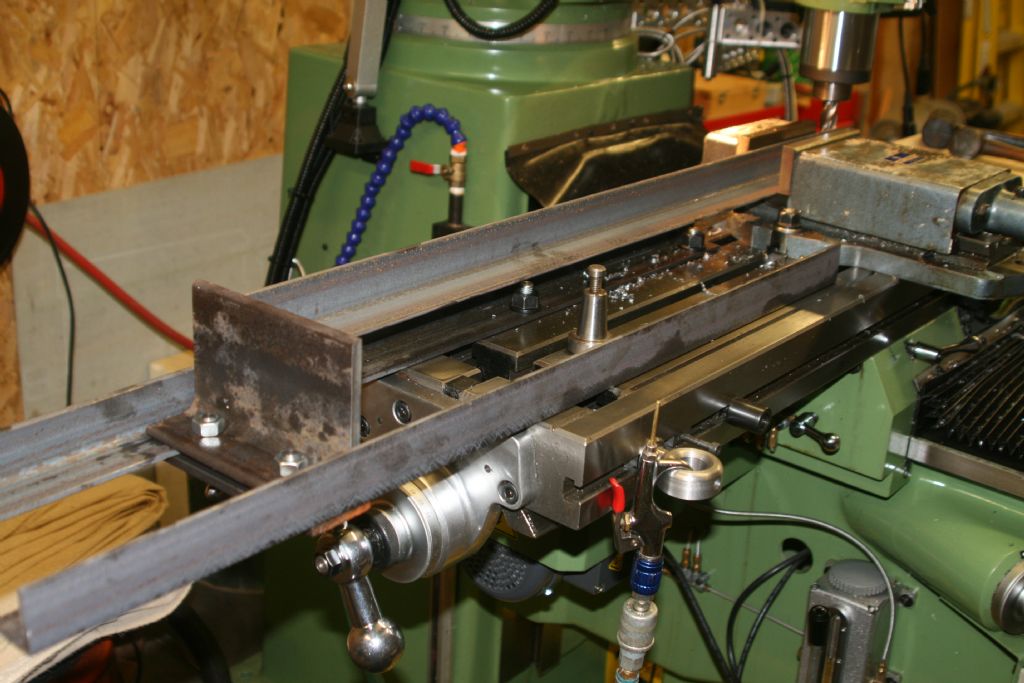

So moved to a Stepper drive with a M16X2mm leadscrew.

Here is the drive and head mounted on the welder frame.

View of the frame – High current sides wired up.

Transformer fitted and wired, with the 4 flexi-cables ( 280sq mm total) in place.

Next is to wire the mains input side, contactors, timer, and to make a pincer contact closure detector – will try to use a 5KHz signal fed onto the secondary – the inductance is very high, so the impedance should not drop the signal level much, but when the pincers make contact the signal should drop to zero – then I know to advance the stepper N turns to develop pinch point pressure, and start the weld…

More to follow..

Joe

Edited By Joseph Noci 1 on 14/12/2017 20:55:55

Another JohnS.