Today I returned home from a three day stay in my local hospital during which I had a three hour procedure to have my abdominal wall rebuilt to cure a massive hernia that occurred following surgery to remove my Gal bladder way back in 1986 pre-Keyhole surgery days.

I can't say it was a pleasant experience, especially since the Morphine pain relief made me feel so sick that I decided not to use it and had to bear a couple of days of agony, however The local hospital (Stepping Hill, Stockport) made the whole thing much better than I thought it would be.

The consultant, ( a Polish surgeon) and the nursing staff were absolutely marvellous landlocked after me well. The small ward I was on had only 4 beds so it was relatively quiet and even the food was good.

How can you fault the NHS.

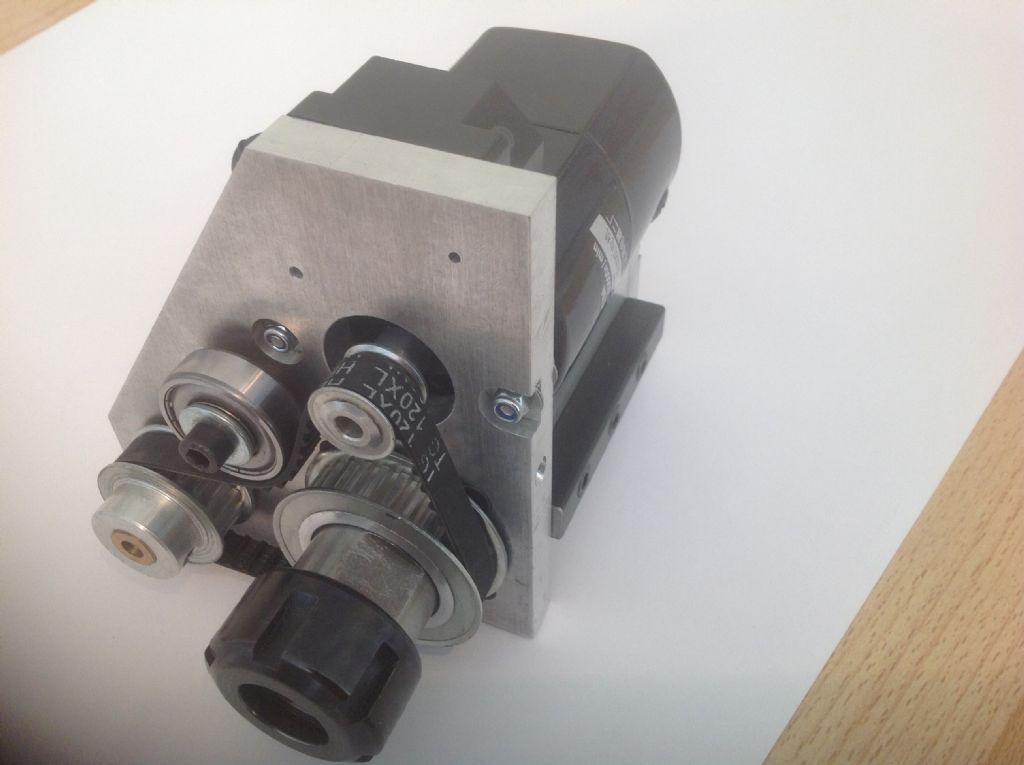

Workshop activities are off for the next couple of weeks but I have got some CNC video stuff to upload onto You Tube that should keep me occupied.

Another JohnS.