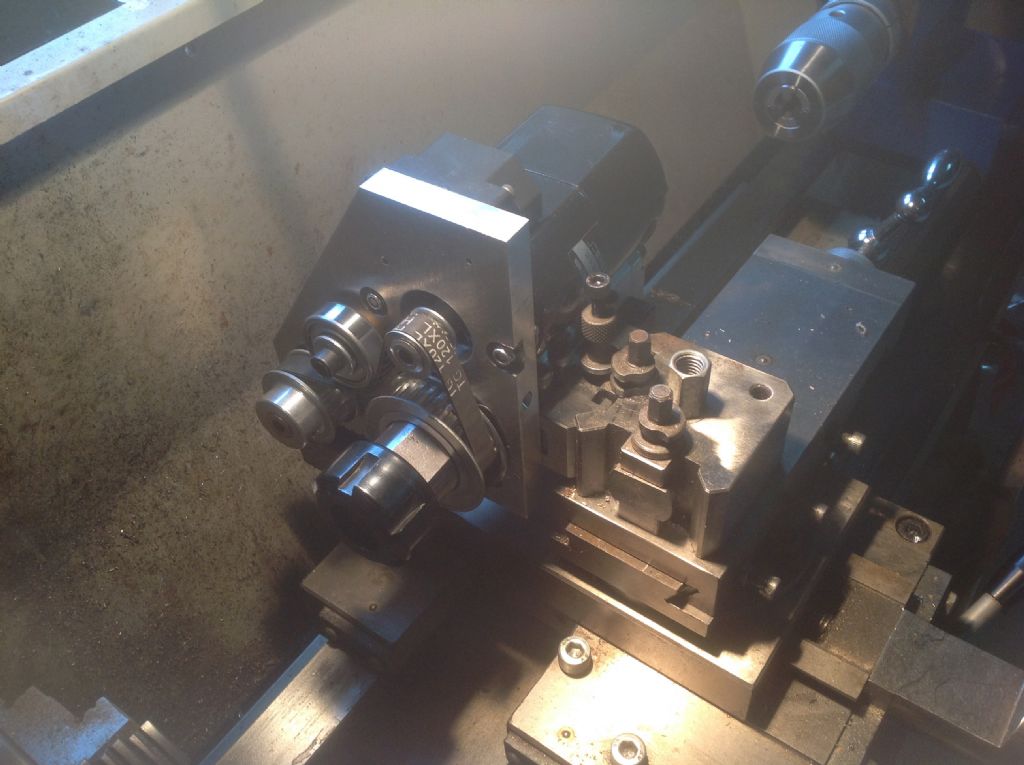

Not done a lot I can post, finished up tonight doing 10 bungs for some hydraulic gear they can't buy.

On the carriage here, just need the hex and thread [ 30 x 1.5 ] on tomorrow.

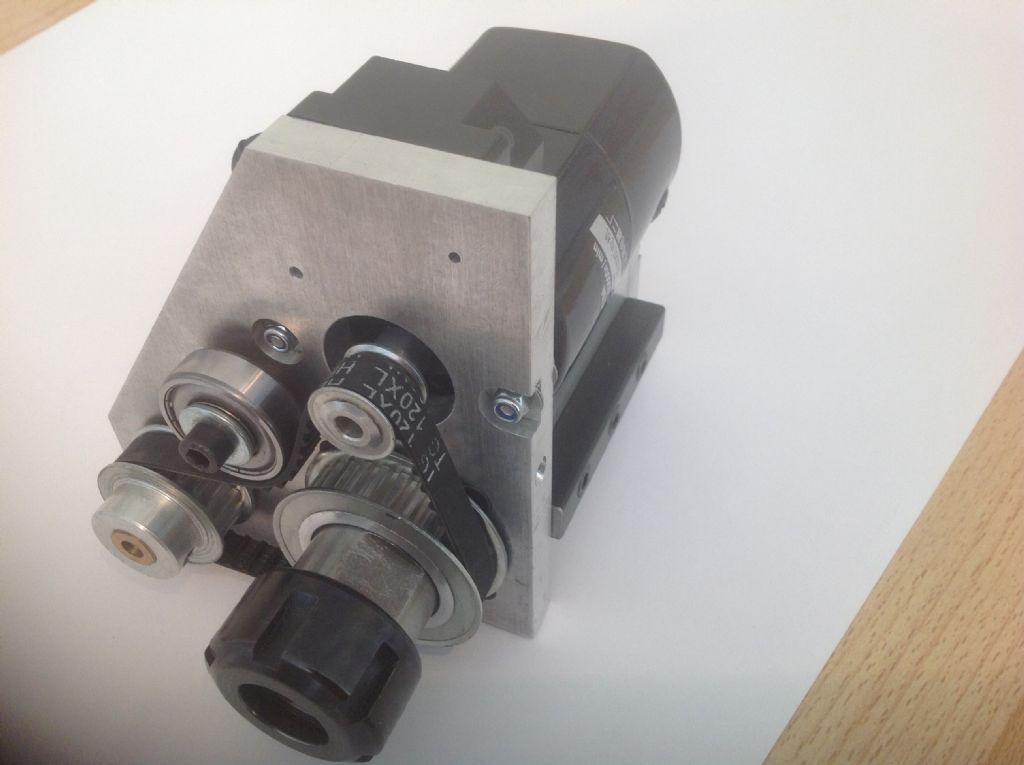

But then spent 10 minutes contemplating if this would fit.

The big one that is, according to my ruler should have 5mm to spare but it looks too big to me.

Oh well, find out tomorrow.

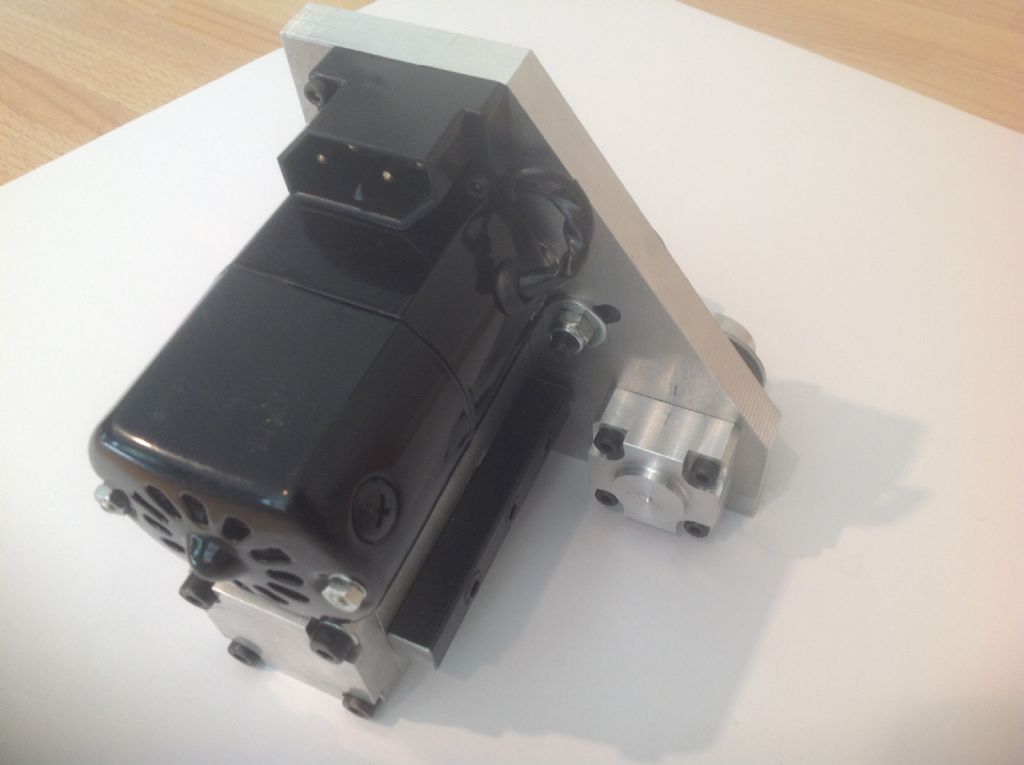

BTW the small armature is a lesson why you should not run motors with low batteries. This is off a fork truck, main drive motor. It's been run with low batteries which drops the volts but still leaves a high amperage and no cooling.

Result is it's let go on some of the hight temp soldered joints and thrown the windings. So a full rewind job and it's on strip, not wire so these have to be formed specially. It's also down on both bearing diameters, my job.

But that quick I'll just load two pallets before it goes on charge will cost them the best end of £1200 by the time the rewinders have finished with the motor.

Edited By John Stevenson on 29/07/2014 22:39:53

John Haine.