Does seem odd.

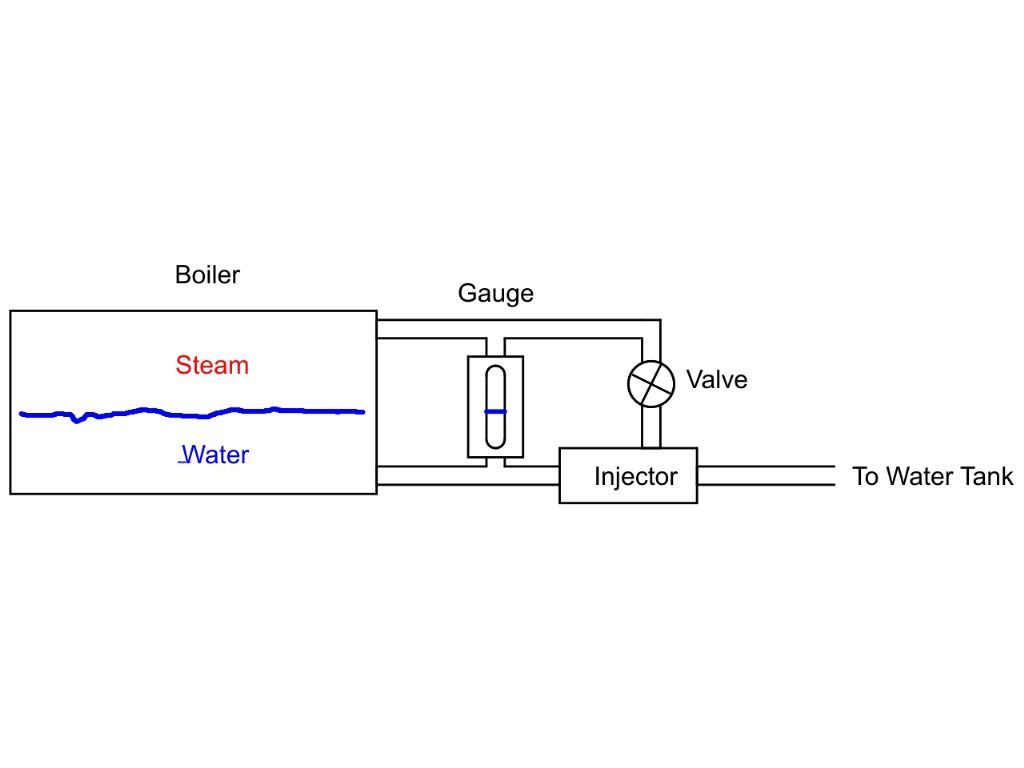

I can understand why the gauge would use independent steam and water connections; and why the connections should be direct – as explained. In fact all the designs and engines I have seen – full-size and miniature – follow those two principles.

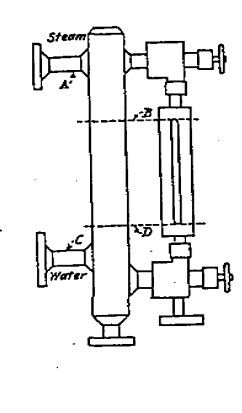

However there is no obvious reason why the water and steam connections cannot be linked, unless such designs have given rise to odd problems of their own. It would be very unusual, but some full-size boilers, especially in very large plant installations had such a column as part of an automatic shut-off that operates if the glass breaks.

I have consulted The Good Book… aka Handbook For Railway Steam Locomotive Enginemen, (typesetting was cheaper in them thar days) pub. British Transport Commission, 1957.

This shows the normal gauges with glass and three test-cocks, but also shows a type with a pipe behind the glass, and with two test-cocks in that. A note, "Copper Firebox Backplate", on the cross-section of fitting and mounting, suggests GWR. Crucially, this pattern also has a ball-valve in the water fitting below the glass, so I assume this too, is an automatic shut-off, though the text does not say so.

If anything a parallel water column might ease oscillations in the glass as the water in the boiler sloshes about, but on its own, not part of a safety device, would make no difference at all to the gauge-glass' action. In which case it's a needless complication.

I can't help thinking the restriction in the Code is more "not invented here guv'", than serving any real purpose.

Nigel Graham 2.