Michael makes an excellent point about skateboard rollers. Readily available, proper bearings, more than up to the load and all the pesky details sorted so they just work.

Size isn't an issue if you narrow the seat bit slightly so the back portion sits inside the frame. Plenty of room for wheels then.

Your drive system appears to show the motor at the bottom with the screw working in compression. Wrong way round as it will try to buckle giving a bending / whipping effect that will send nut friction through the roof. The screw must be hung from a bearing at the top so its in tension. Bearing needs to be fairly free and the nut in a pivot so it all takes up its natural position. Look at the old style car "plug in the sills" side-jack. Engineering standards are applied crudity really but they lift half a ton with no great trouble.

The original EasyRizer used a simple Allthread screw of similar dimensions to what you are using and was frequently demonstrated with a Honda Gold Wing perched on it running up and down under drive from a fairly ordinary, albeit good make, battery screwdriver. If yours has so much friction that it won't lift a person you have some serious fundamental design issues.

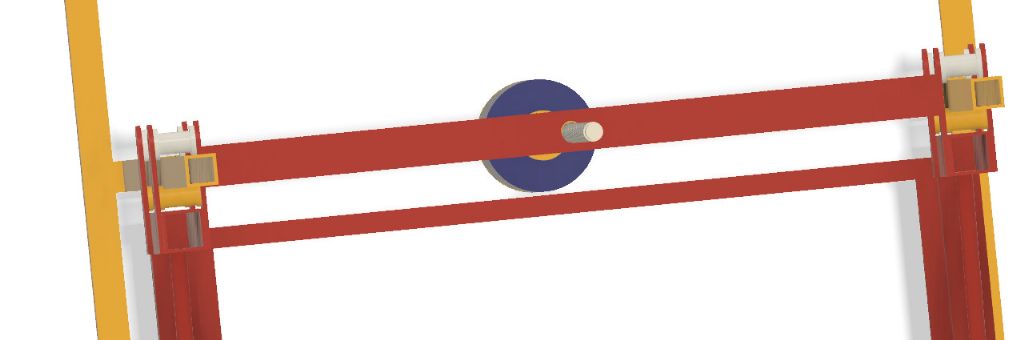

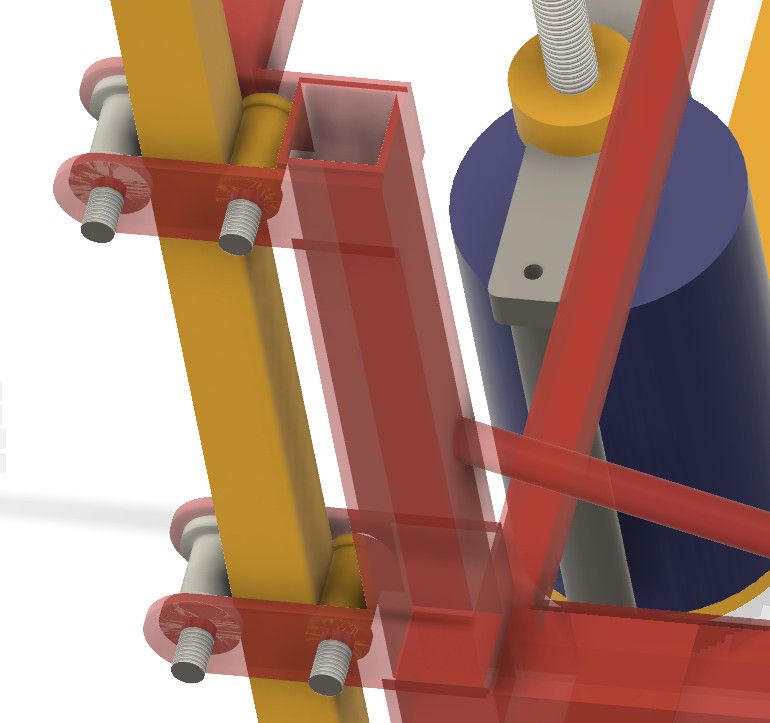

I'd scrap the "door frame" and go for a single column with two triangulated braces back to the rear foot extensions. Picture shows the guide roller end of a hydraulic lifter rated for something over half a ton on a platform similar to, but rather larger than a person seat. Perhaps approaching double the effective overhang. Weight limits set by the hydraulic pressure and base details not column & guides.

Main tube is 2" by 3", axle pins are about 3/4" diameter on approximately 5 1/4" by 4" centre. Rollers are about 1 1/4" diameter with a 2" (ish) flange on one end. The other flange is free running. No significant side to side wobble when loaded although flanges just barely don't touch the main tube. I imagine there is reason for one flange on the roller and one loose. All steel. Made to rusty industrial "keeps on going" standards. The actual lift is between the lift guide tube and the platform. A top hung screw would work just fine. That one has a simple vertical hydraulic cylinder in a tube which connects the top of the hydraulic rod to the guides and platform. Tube also protects the rod when extended. For a screw version simple overlapping covers would seem more than adequate to keep things out of the works

Always remember being told many years ago when struggling to make one of my genius ( aka stoopid) ideas work "When your are in hole stop digging and copy something." Advice I was young and hung ho enough to ignore at the cost of a weeks worth of spare time to end up with less than stellar, albeit more or less functional, results.

Clive

Edited By Clive Foster on 03/08/2019 15:43:46

Edited By Clive Foster on 03/08/2019 15:45:23

Sam Longley 1.