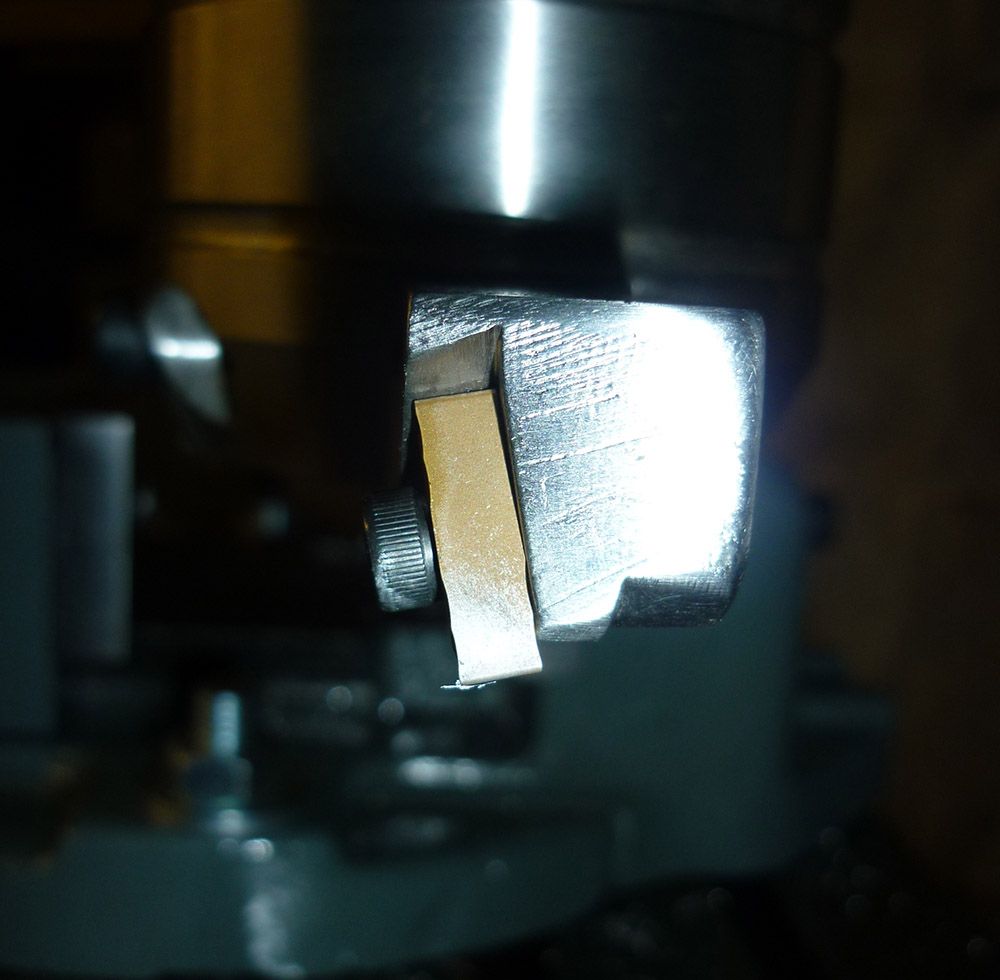

Well i decided to try the inserts ,using M4 high tensile caphead screws. I reduced the diameter very very slightly so that the screw would pass through the insert which happens to be 3.81mm for some reason. I managed to drill and tap for the screw accurately and when screwed down appears rock solid. I had to guess the lean back on the toolholder for clearance for the insert. The bar is an old 20mm Sq. lathe tool shank.

Some photos showing the flycutter adapted onto a morse taper 4 stub arbor the actual fly head is pretty heavy and around 3" x 3" steel. I read that a higher mass head puts less stress on the head bearings. It appears to work great with no shaking .juddering or noise. I made two keys to mate with the flats on the arbor .

I tried auto feed at first the aluminium block didnt seem to like the slow feed (i unfortunately at the moment cant really change the feed speed as i dont have the set of change wheels for the mill.)

I tried a slower speed and quite fast hand feed and this is the result. Not quite mirror finish but almost. This is my first attempt at flycutting and i dont know if i have the correct inserts .Maybe sharper polished ones specifically for aluminium would give a better finish. The suburban tools type specify tnmg 243 inserts but im not sure what they are . The ones i used are made by walter and seen above ,i think they have a 0.4mm radius, maybe a larger radius gives a nicer finish ,i dont know.

Edited By mark smith 20 on 21/09/2017 20:20:37

mark smith 20.