Broadly speaking, Nigel B's first post is correct.

Some notes:

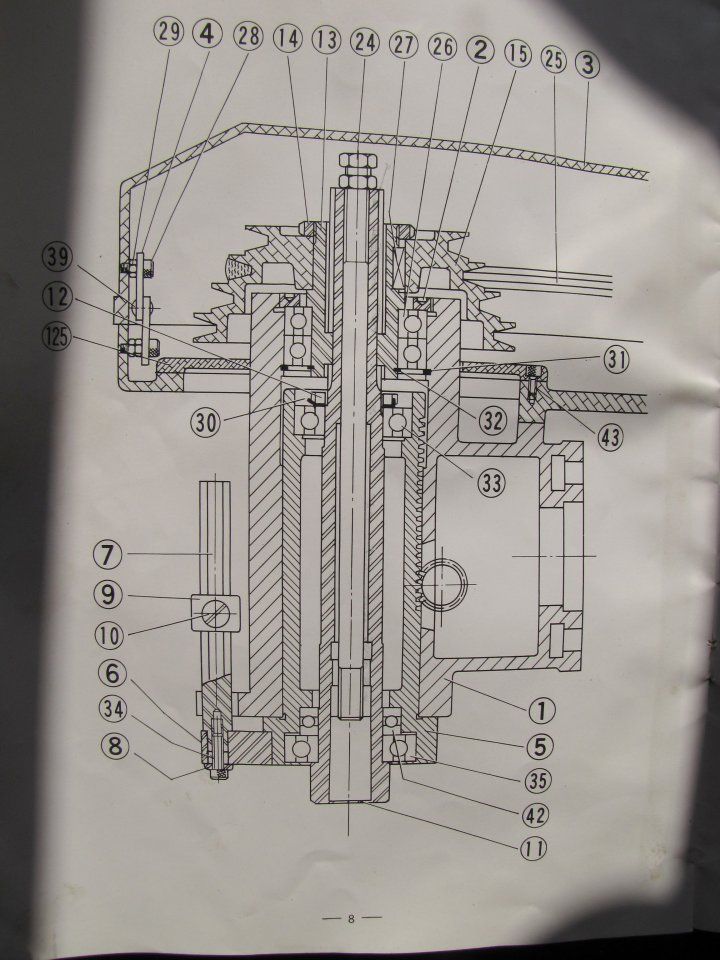

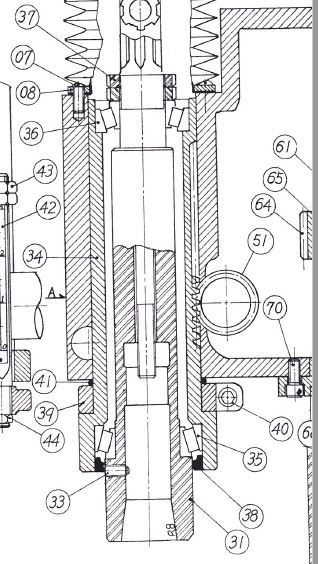

– I am not so sure that the bearing at the working end of your mill is a sealed bearing. It is likely to be some kind of angular contact bearing (ball), or taper roller bearing. Have you got an exploded diagram to guide you – giving you bearing number for the bearing involved?… before you go any further, this is the first thing to check to see what kind of bearing/s are you dealing with.

– Grease/over torque possible problems. How regularly have you been using the mill before changing over to VFD?.. Is the machine old/second hand… and do you have any history about its use before the change to VFD?

– 2000 rpm is not exactly high speed. If it was a sealed bearing, and machine not really used over time, then you may have a grease problem/issue. What was the speed before, and what is it after?…So, what is the percentage increase? have you checked this?

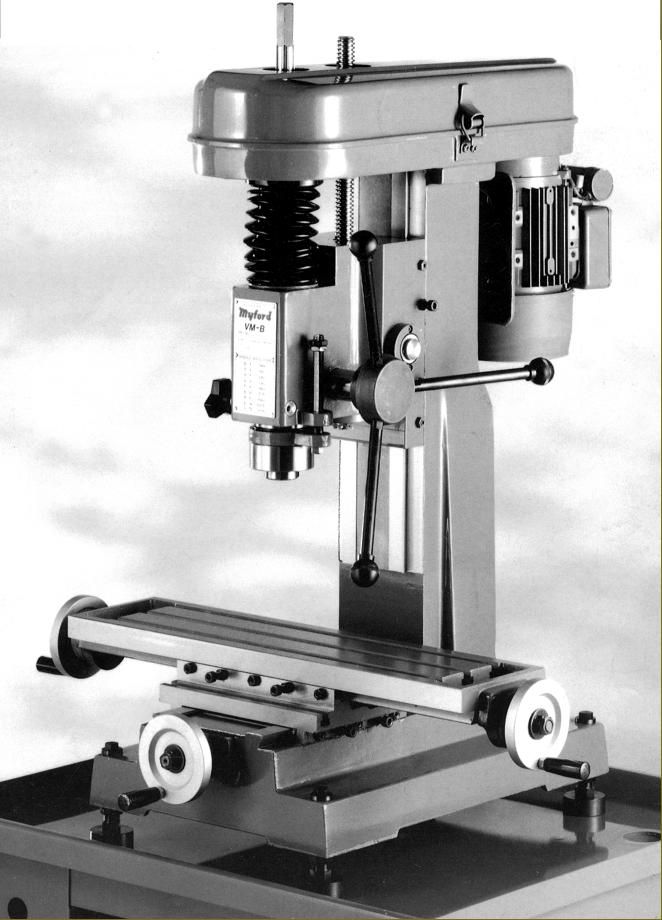

– When you changed to VFD, did you make any mechanical changes?… I don't know your machine. Is there any belt drive to the spindle?… If so, was there any extra tension introduced introduced to the belt after the change over?

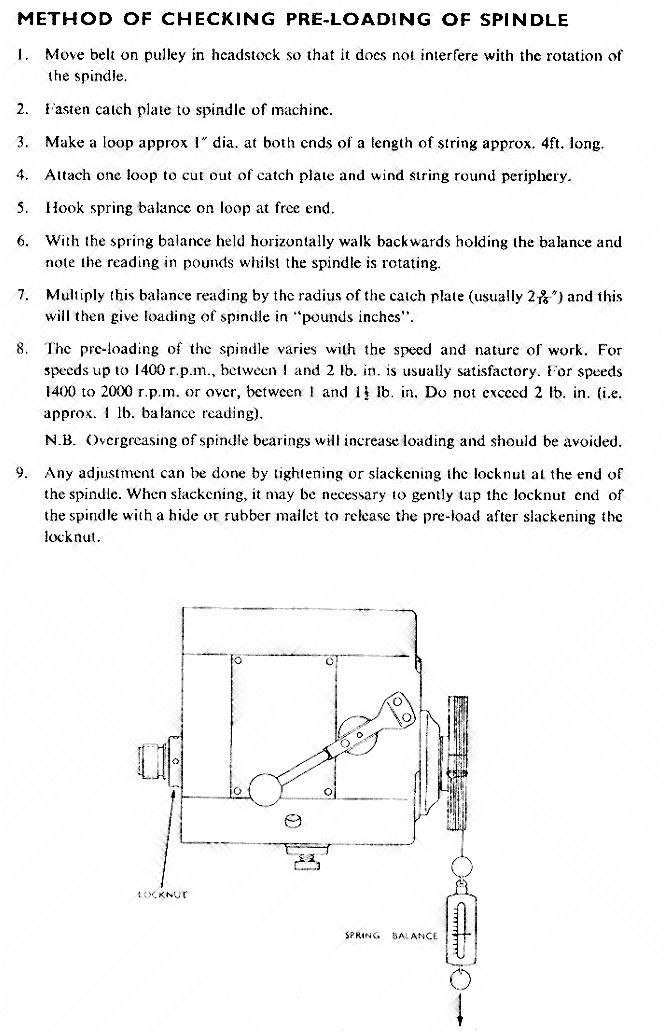

– What is the method of applying pre-load to the bearing? Are there some kind of pre-load nut/s at the top of the spindle which may have been tightened during the change over?

– As Nigel said, less grease is better than more. I would say between 20 to 25% of internal volume… provided it is not a sealed bearing. In your particular case, normal LM grease – Castol NLGI2 or similar is fine. You will be wasting money on special grease which is not really going to do anything special in your particular case. If you were doing 5000 rpm +, maybe more specialised greases would start to come into play.

All said any done, there is no point in disassembling the spindle, until and unless you know what you are dealing with to start off with. The answer can be simple or complex, and as Martin Cargill said, dismantling a spindle assembly should not be taken lightly. Changing the bearings (only as a last resort), re-assembly, torque and running in process there after are another thing altogether.

Ketan at ARC.

John Haine.