Thanks all – lots of defence for the "fixed stem" version, but that's what I have and I generally find it a complete hindrance…I get all the angles correct and can't tighten the knobs as the brackets are in the way, so you have to re-arrange everything, and it becomes a mini-project just to get the DTI where I want etc

@Ketan – my probably "60kg pull" version is pretty hopeless, it won't support itself at reasonable extension with a DTI fitted when stuck sideways onto the mill column. It might be 60kg to pull it off vertically, but it rocks sideways far to easily IMHO. Mind you the Noga is only 81kg pull so not a huge difference, and the sideways grip isn't defined

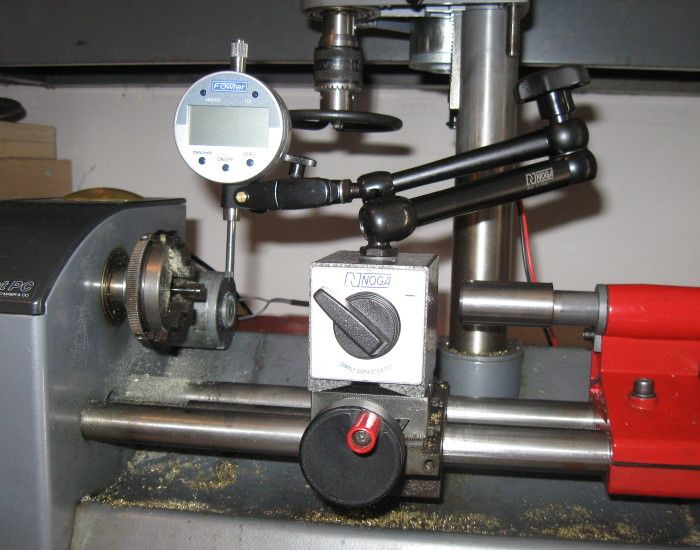

@clivel – those were pretty much my thoughts – it seems that it's as easy to set up the the DTI travel axis at just about any angle in just about any position in say a 9" diameter sphere resting on the top of the mag block as any other position and just as quickly and with a fine adjust when you get there (OK, not every point on the sphere probably, but the articulation of the arms and the holder does seem remarkable)

..and then I noticed a "20% off everything on eBay until 12:00 tonight" email I got today, so decided to pull the trigger on the Noga – only to find the 20% off redemption code has run out of its funding

So still not ordered, just yet – I see they are available in the UK at about 20% more than eBay from the States (so the same price if I get charged VAT on the incoming package)

http://www.mqs.co.uk/noga-dg61003-noga-magnetic-base-type-on-off-switchable-magnet-magnet-size-50x60x55-wxlxh-bottom-arm-length-110mm-top-arm-length-101mm-holder-length-71mm-over-all-length-282mm-force-800n.html

Edited By Martin Millener on 15/06/2015 23:12:58

Ketan Swali.