Posted by John D 15/10/2022 21:51:34

Does anyone know if it might be possible to obtain the elevation gears for the Myford

VMC anywhere? I suppose best bet is knowing which machines it was the same as

(at least in respect of the gearing for Z axis). Mine has some roughness when

lowering the knee and, although better on raising, still not perfect. You hear a

click click click on when lowering. Everything has been cleaned but i cannot

see any way of adjusting the gears.

Wondering if they are all like this?

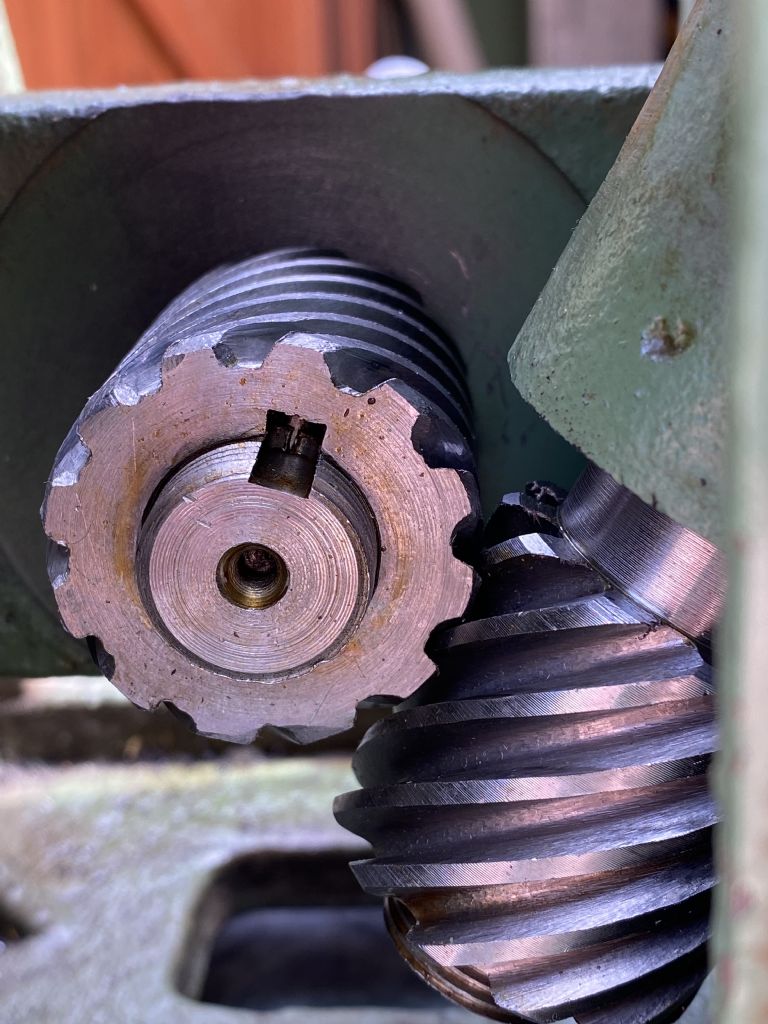

Photo of gears cleaned up and with the retaining washer and nut removed.

All greased up with fresh grease but no different.

————————————————————————————————–

Those gears look about normal and are much the same on my Warco

2 AF mill ,the backlash on my machine is shown as 0.0015 " on the

index dial so you look to have excessive backlash on your machine.

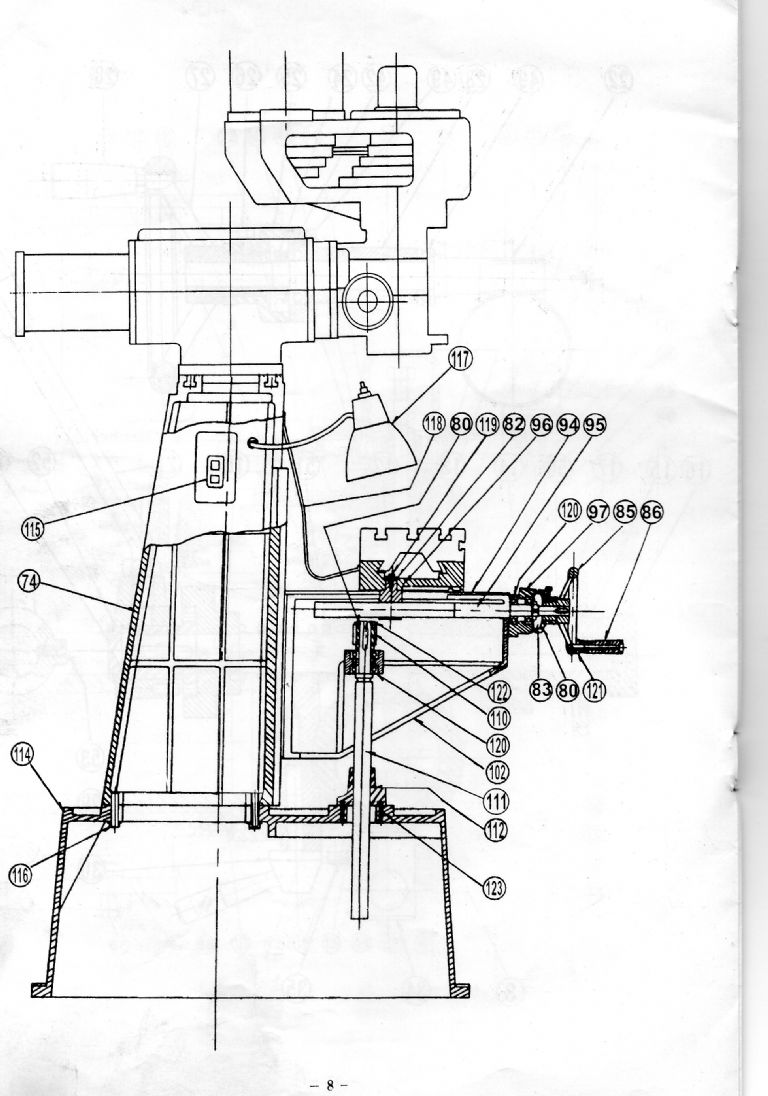

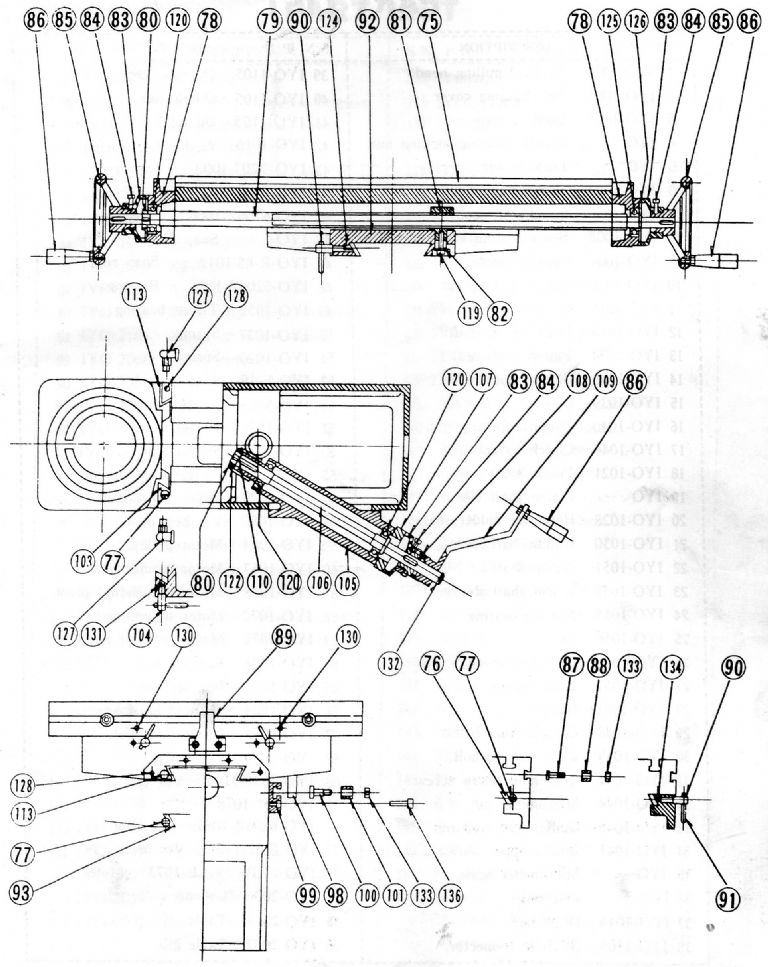

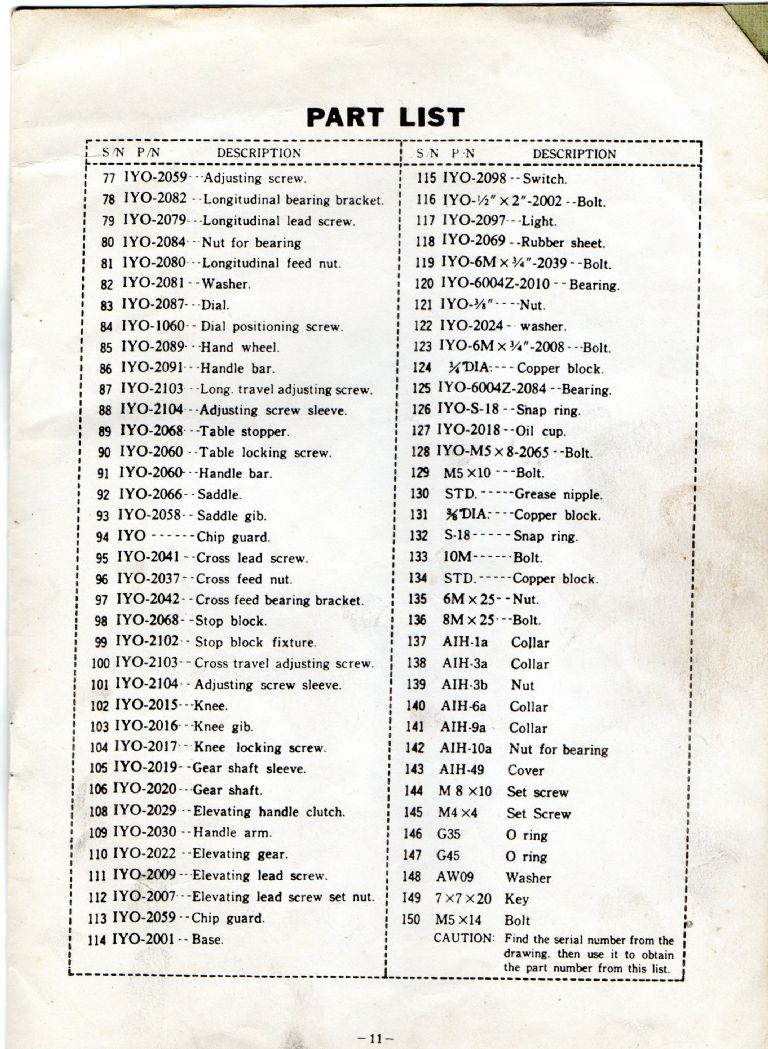

As far as adjustment goes the knee and gear shaft sleeve as depicted

in the following images are 2 separate parts 102 and 105 ,i expect the adjustment

for the backlash is made on assembly after which the these parts are filled

and eventually painted over to look as one piece.

You can soon tell if this is so as if you feel up inside the casting you may

find the holes or bolts protruding.

Even if you find a supply of new gears they may fit exactly the same if

the adjustment was out from new.

It may well be possible to adjust the mesh unfortunately it would mean

digging through the filler and paint to find the bolts to dismantle and

adjust.

When i got my A2f from Warco these 2 gears were very rough in operation,

i mixed some green label fine Timesaver abrasive in with the grease and

after a short time they were as smooth as silk ,this abrasive is non imbedding

and can be left on as it eventually becomes inert , i use this grease on these

gears "Rocol 18302 Tufgear Universal Open Gear" it is more suitable.

You could turn off about 1/8" off the top of lead screw gear and refit it with

a 1/8" washer underneath likewise also with the input gear to

establish a new contact point on the gears.

John

Edited By John P on 16/10/2022 12:07:02

John D.