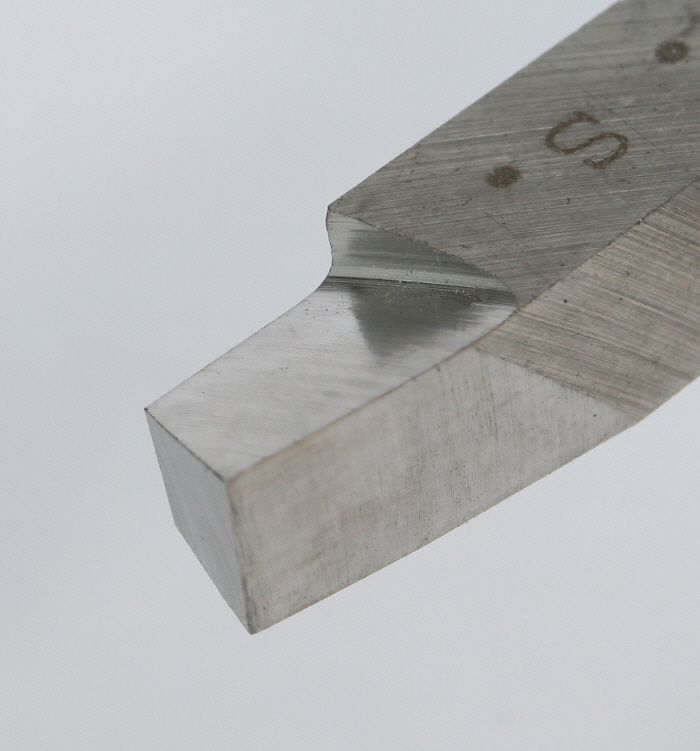

Your piece of steel looks, to me, to be torn, rather than cut cleanly.

This suggests to me possible causes, whether in isolation or in combination. A tool that is not sharp; tool off centre height; or wrong cutting speed for the material.

You might do better to use a High Speed Tool, which can be ground on an average grey carborundum wheel.

Not clear from the photo that your brazed carbide tool is really sharp.

Grind the HSS to give 5 degrees clearance on all faces, front, side and top (otherwise known as "rake" ) For these purposes, The exact angle probably does not matter too much as long as it is somewhere between 5 and 10 degrees.

One thing which has not been mentioned, is one of my hobby horses, setting the cutting edge exactly on centre height. Too high and the tool rubs rather than cutting, too low and the clearance angles are wrong.

A quick check on the tool, being at centre height is that when facing, there should be no "pip" at the centre. If there is, the tool is not at centre height. Shim it until there is no "pip".

My advice would then be to make up a simple centre height gauge.

PM me with an E mail address, and I'll send a picture of the one that I made, and constantly use.

Once you have confidence that the tool is sharp and on centre height, you can begin to look at the ".What is itesium?" that you are trying to cut.

Also, what is your cutting speed? For Mild Steel, most folk would be aiming for about 100 feet / minute.

So for 1 inch diameter, the speed should not exceed 380 rpm. If in doubt, go slower.

Don't rush the feed. Difficult to estimate, but try to aim for about 0.004" / rev.

Don't be so slow that the tool rubs, rather than cutting. This generates heat which softens the tool so that it looses its edge, and becomes blunt. And so the vicious circle continues!

For this you have to learn how to turn the traverse wheel at a constant sped. This will require both hands, smoothly changing over the drive from one hand to the other.

You could use the power feed, via the Leadscrew, but that is a complication far too far for you at this stage, I suspect.

Also, putting a small radius on the cutting edge of the tool would improve the finish. But DON'T try this yet, or you might make the tool rub.

You have taken the first steps; just build on these. You need to to learn to walk before running!

These more advanced techniques can come after mastering the basics. We are all on a learning curve. None of us know everything!

HTH

Howard

Steviegtr.

Steviegtr.