If your lathe is a ML3 it will have a Centre Height of 3 .500 inches and be 15" centres.

All threads will be Whitworth form whether BSW or BSF (Gib adjusters may be BA )

the ML 1 and 2 were 3.125" Centre Height. Odd Nos were 15" Centre distance while the evens were 24"

Take a look at Lathes UK pages for Myford ML1,2,3 and 4 lathes, to confirm what follows.

The very earliest, probably 1s and 2s had the Headstock cast integral with the bed. On later ones the Headstock was secured to the bed with four 1/4 BSF studs and nuts.

Be careful not to overtighten the clamp type Mandrel bearings, lest you crack the casting!

With the mandrel running in the cast iron, it is not a high speed machine

Mandrel and Tailstock bores will be 1 MT from memory.

Assuming that no one has changed the spindle, the early ones used a 7/8 x 9 (7/8 BSW ) thread for the Chuck.

This was later changed to 7/8 x 12 tpi.

It is rumoured that some of the vary last machines used 1.125 x 12 tpi, like the Series 7 machines, but without the register..

If you want to use chucks, or backplates for the 7 Series, you need to make up an adaptor, with spanner flats, with the external 1.125 x 12 tpi, Whit form thread and 1.250" register, and an internal thread to suit the 7/8 thread on the Mandrel. Machine the register when the adaptor is on the machine, to ensure that is as concentric as possible.

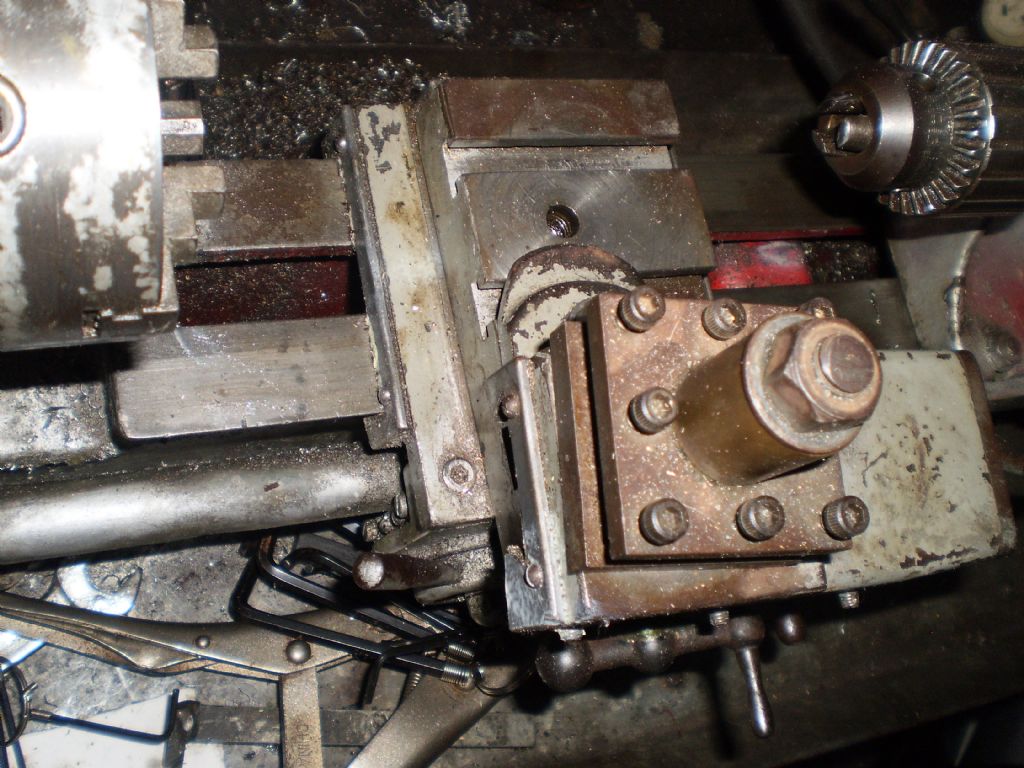

You will already have found that the Saddle Handle is ungeared, so that rotating it clockwise moves the Saddle TOWARDS the Chuck, and that Changewheels are driven by 3/32 pins connecting them to the driving collars, or together for compounding.

Series 7 gears can be used, being the same dimensionally, but needing a 3/32" hole drilled for the pins, instead of using the keyway. This will probably mean drilling right through one gear to ensure that the hole is on the correct pitch circle.

The Leadscerew is 8 tpi, but being right hand needs two Idlers to move the Saddle towards the Headstock, whether power feeding or screwcutting..

Cross and Top Slide Leadscrews are 12 tip, and the dials have 80 graduations, so each division is not exactly a Thou! (0.00104"

To set a fine power feed, you would be advised to get a couple of extra 20T gears and a 60T., and maybe make up an extra Stud.

In this way a 20 : 60/20 : 65/20 : 60 train will ,give a fine feed of 0.00427" / rev can be obtained. You might need to fettle the inside ends of the Banjo to enable all the gears to mesh correctly.

The 20:65 mesh ensures that the two 20:60 trains do not clash.

Set each Mesh, starting from the Leadscrew with a sheet of paper between the teeth, to give just a little backlash

The Tailstock barrel is prevented from rotating by by a 1/4 BSF grubscrew, with a "Key" on the end which engages with a keyway in the barrel. The grubscrew cannot unscrew and fall out since the keyway in the barrel prevents it rotating

.HTH.

Howard

Howard Lewis.