Posted by Roy Garden on 21/03/2019 23:38:16:

Gents, I'm profoundly grateful for the advice, thank you all.

Through some budding bodgineering (which is what I aspire to) and using hints and tips from this thread, I've kind of got close to what I was after.

The "nail it to the table, and spin it round" advice kind of covers most of the equipment I currently have.

The "File it, it's faster and easier" Well, I have a car, driving to get a bacon buttie is fast and easy, flying there is a pain in the butt, slow, unreliable, fraught with wasted effort, but good fun ! (99 times out of 100, I'll take the easy option, but when it's new . . I'll go with the wasted effort just for the experience)

Can I file? Yes.

Do I want to file? No, that's why I bought a belt sander.

(Tho, having said that, I've never heard of using bearings whilst filing, Can I get a link for how that works? )

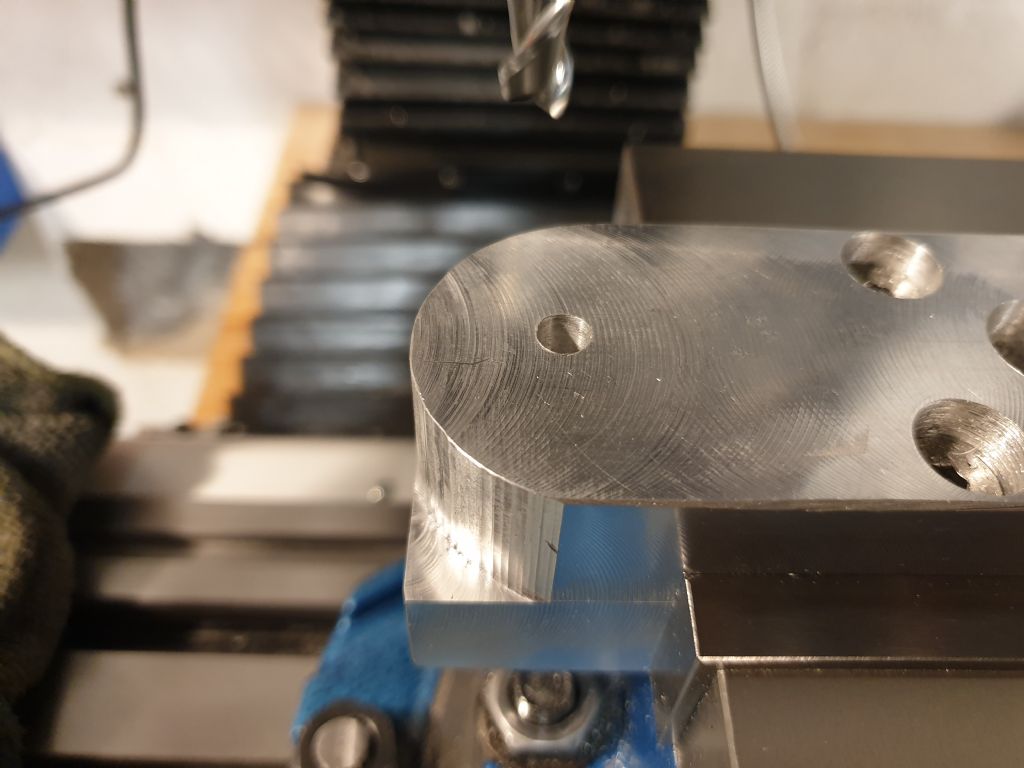

I went with the "Pin through a hole and rotate in the vice" method, Sadly, a long (ish) piece of work and a low vice meant I managed very little of the curve that way, but enough to get a "feel" for the shape, 5 minutes on the belt sander and, from a distance, with yer glasses off, in low light, it kind of, looks ok.

Probably 4 hours time playing with the mill today, I think the finish looks good (it's what I wanted to see)

I'm discovering that "machining" is probably best done by fairly accurate sawing, finished off by machining the bits the saw can't do and providing a surface texture.

An hour spent cleaning (that's new to me too, I'm sure I'll get faster) and the garage has a shiny, uncompleted "bit" in it, a clean shiny mill, and a happy bunny who is now waiting for more "essential tools" to arrive.

In the meantime, I can pick the swarf out of my socks . . .

(and try to hide the battery Dyson from the wife, it looks a bit sad for having eaten lots of aluminium swarf and WD40)

Thanks again, I shall be asking more questions as I blunder along the learning curve.

Edited By Roy Garden on 21/03/2019 23:42:20

Edited to remove oil rig language.

Edited By JasonB on 22/03/2019 10:03:55

larry phelan 1.