Posted by mechman48 on 16/09/2016 17:08:29:

… Also, I realised that the milling attachment may also fit other types of mini lathes, but I do not have their dimensions,

would some kind fellow model engineers who own a Grizzly, Harbour Freight, Sieg, Clarke, etc

7 x 10, 7 x 14 lathe please PM me.

regards Dave Archer

As I read it are you planning to make these designs for your own benefit / forum readers / for sale, if so what pricing are you considering?… or have I got the wrong end of the story?

George.

Hello Bob and George,

I have had the Amadeal CJ lathe for well over a year.

I live in a small flat and do not have space ( or money ) for a £ 800 mini-mill and table, tooling and everything else that goes with it, although I often need parts made that requires the use of a small mill.

Slots, key ways, through holes, splines, etc.

I have to ask a local engineering company to do these parts for me, which rather destroys the concept of home model engineering.

I realised that thousands of these CJ18 mini lathes are being sold each year to budding model engineers, and also that most of those buyers will be in a similar position to myself.

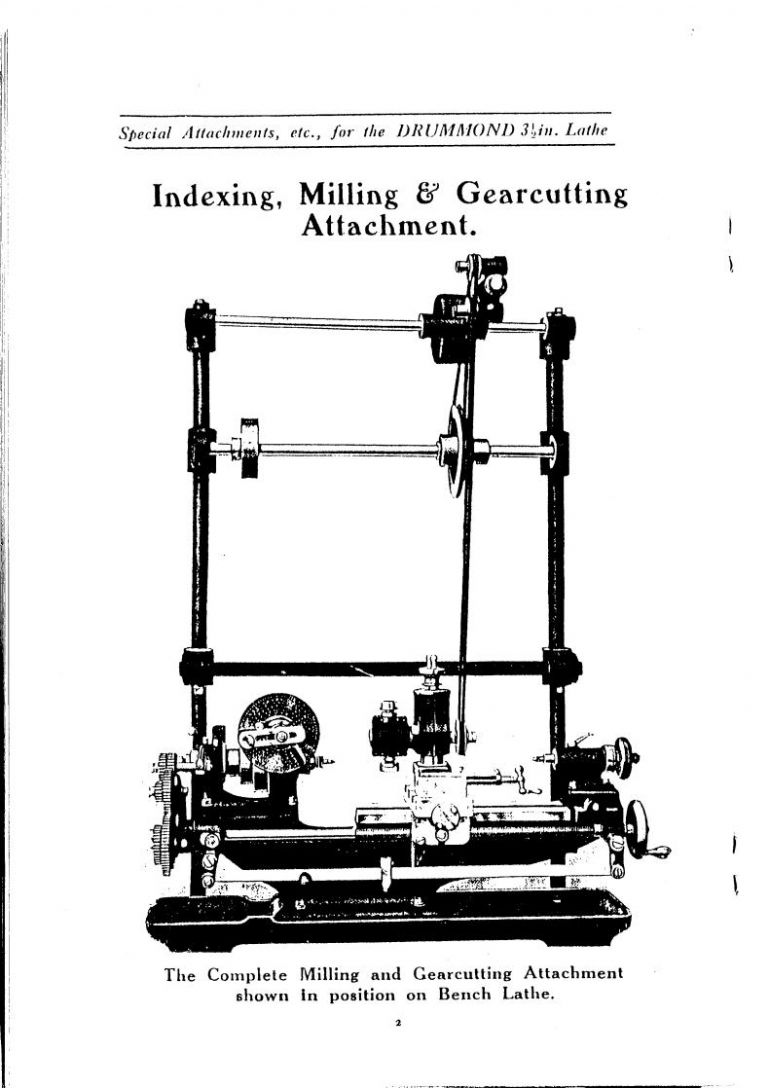

The milling attachment will not be a flimsy vertical mill, sticking a long way up into the air, but horizontal, and the milling cutter / drill / slot drill, will be held in an ER16 collet, right up close to the tool post centre bolt, and so will be extremely rigid, driven with a 500 watt motor, with infinitely variable speed control, built into the attachment as one complete modular unit.

The power control electronics will be in a separate box screwed to the wall behind the lathe.

I am in the process of having investment castings in solid Aluminium for the main body made, have applied for a Registered Design, and I am waiting for the working model to be completed to start the application for a Patent.

Because of the Patent application, this means that I cannot show a video of the prototype attachment working, which is a bit annoying.

As I read it are you planning to make these designs for your own benefit / forum readers / for sale, if so what pricing are you considering?… or have I got the wrong end of the story?

Yes, this unit will be for sale, as a complete kit when completed. I think that I can keep the price around £ 300.

Primarily for the CJ18 lathe owners, because I have already sussed out all the dimensional problems, but maybe later for the other variants of mini lathe out there.

regards dave

.

Neil Wyatt.

Neil Wyatt.