Apologies to all for this belated response. I have been away from home and also somewhat distracted by my attempts to improve the fit of the butt of a BSA Martini International .22 target rifle – one of my other interests.

Basically, Hopper is absolutely correct in his advice. It has been confirmed by Paul at Meddings (very helpful).

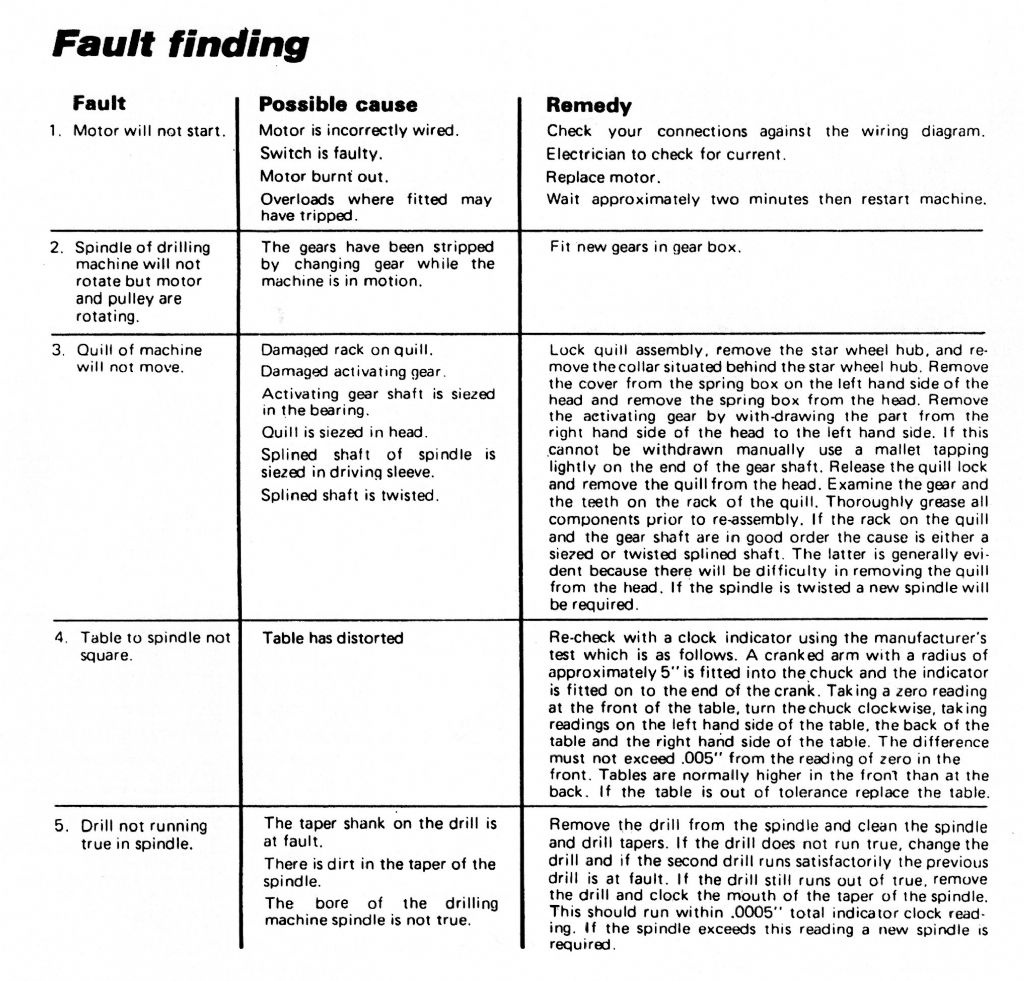

Undo the grub bolt on the underside of the part of the body holding the return spring. You can then left off the latter. It comes off in one piece, with no fear of the spring acting like a jumping jack, provided you prise the inner part of the spring from its slot in the pinion shaft.

Prevent the quill from dropping by use of the stop nuts on the scale rod.

Undo the other small grub bolt on the underside of the wheel side of the main body. (This was missing in my case, which makes me suspect some tampering in the past.)

Then tap the pinion shaft out from the the retrurn spring side. In my case this required considerable force and a heavy mallet (cushioned by a piece of wood). I am wondering whether the shaft was/is not binding in the nylon sleeve that locates it in the main body.

Then take out the quill. Check and clean the teeth and the pinion wheel gear. (There was liitle sign of debris in my case, which suggests that my problem lies elsewhere.)

Re-assemble in reverse order with grease where appropriate.

I found the rise and fall mechanism moved more easily after the cleaning, but still not as freely as I would like or expect, and the return spring is still not effective. That is why I suspect the nylon sleeve of being somehow overtight. Or, much worse, perhaps someone allowed the whole drill to fall on its side at some point and the impact slightly distorted the pinion shaft, strong though it is, leaving it to bind against the quill teeth. In that case, there is not much to be done but live with the defect.

Many thanks to all once again – and greetings to Michael Gilligan. I hope the milling machine is proving satisfactory, Michael.

Roger

Richard Savage 1.