I recently purchased this on behalf of my employer and as we keep our manuals digitally, I thought I'd share a copy here as there are none online. Hopefully once enough people have it it will be easier to find once the inevitable digital decay renders the below link dead! I will keep a copy obviously so if you cant get it below, get in touch.

**LINK**

The Naerok mill/drill is quite significantly different from today's Mill/Drills.

The most notable difference is the mill head does not slide up and down the column, instead it is fixed and the column slides through the base.

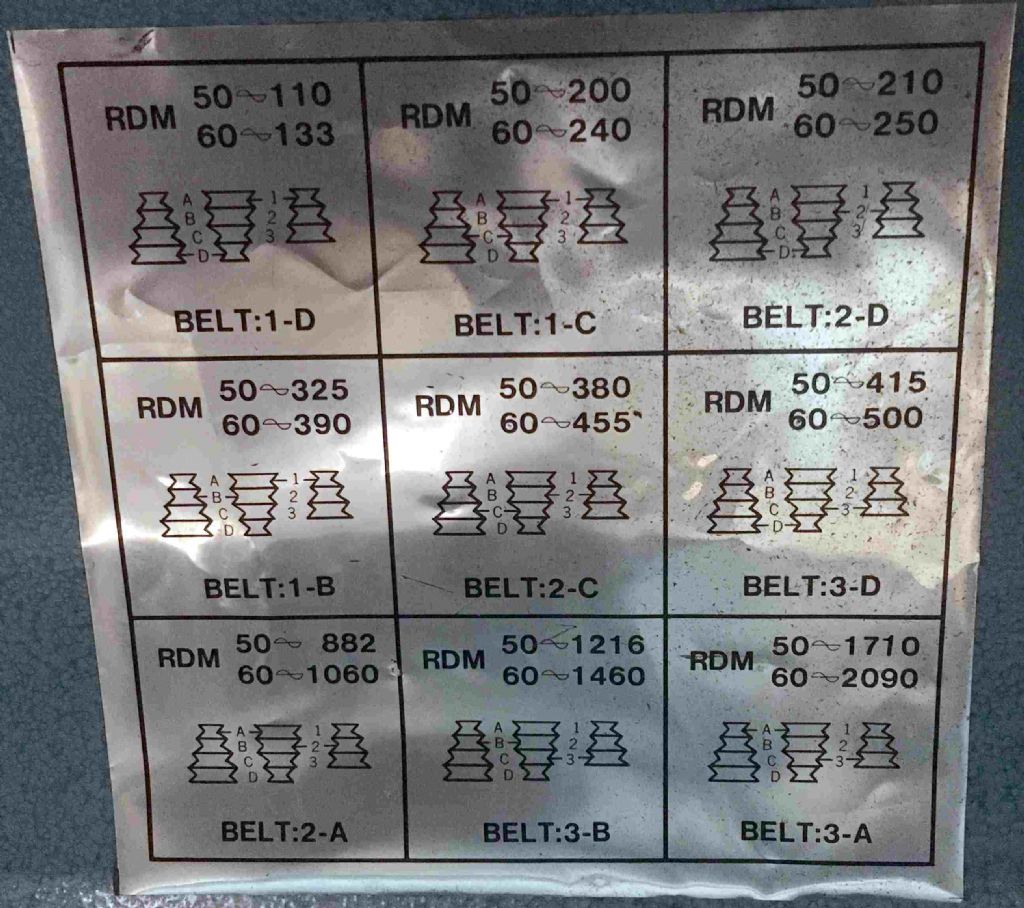

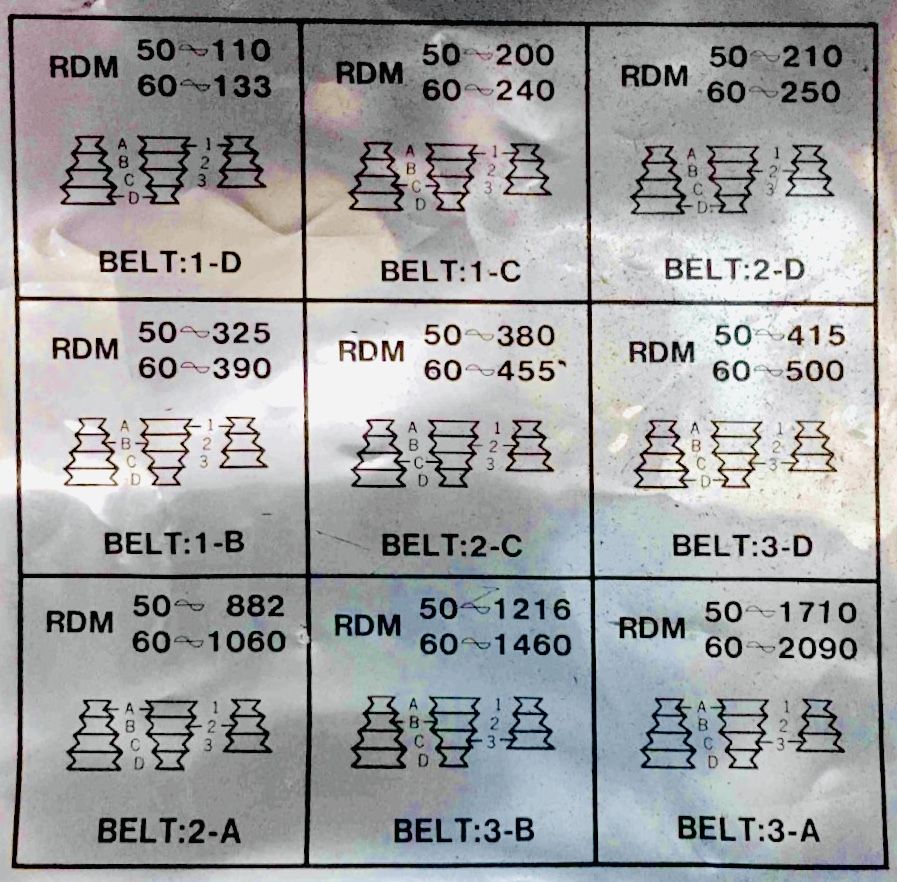

Having purchased and serviced/refurbished 5 or 6 of these round column mill/drill machines of all sizes, I can tell you this one is of a good solid quality similar to the original Rong-Fu machines of the 80's, the leadscrews have roller bearings and overall are of nice solid quality, the castings are much finer than found today. Another example is the belt tension system which is the same, but rather than just pushing the motor with one hand, (which makes it a fumble to then hold it and tighten the motor mount) a lever on the side operates a piston that pushes the motor mount out and tabbed screws make it a simple operation. This is just one example of little luxuries that you don't see anymore, no doubt due to over competitive pricing.

Rong-Fu are still going strong and make their version of the mill/drill machines and a whole load of others but I'm not sure if they're the same quality or perhaps if other copies are on the market too.

Emgee.