I have a Tormach PCNC 1100 series Mill for which, when it came out I bought the Rapid Turn lathe accessory that fits to the bed of the mill to become a poor mans CNC lathe.

In order to increase it's usability I made some gang tooling which has so far proven to be worth the effort.

Recently I had an order for 1,575 sensor buttons that were a simple turning job requiring a 3mm slice taken off a 25mm diameter bar with a rough scroll like finish on one face and a parting off finish on the other with chamfers on both edges. The collet closing system that comes with the attachment is draw tube that is tightened and slackened using a 2" long Tommy Bar that fits into holes on the closer tube end. With a cycle time of less than 1 minute it became positively painful tightening and loosening the collet that many times, especially given that the cycle time was less than a minute so I decided to do something about it.

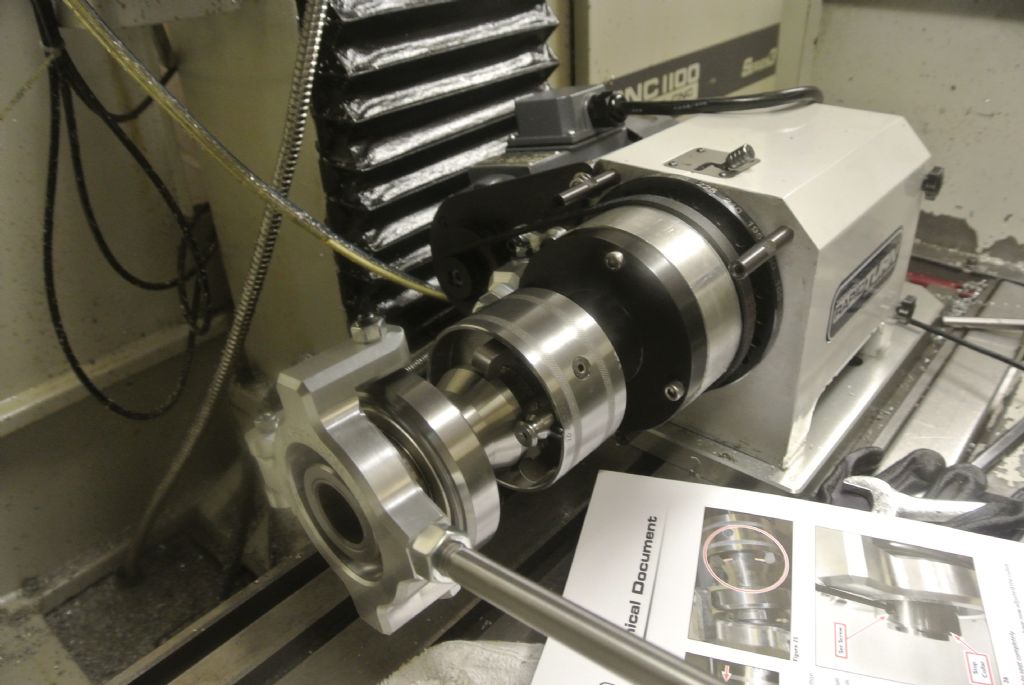

Tormach market a Lever Operated Collet Chuck for their Slant Pro Lathe and I thought I might be able to adapt this for use on the Rapid Turn.

I ordered a unit and it arrived a few days ago so I decided to have a go at getting it to fit. First thing to do was to turn down the draw tube O.D. to suit the Rapid Turn Spindle, next I machined a register on the drive pulley of the Rapid Turn by clamping it to my manual lathe, plugging it in to the power socket on the mill and use the manual lathe cross slide/toolpost with a trepanning tool in it to cut a register in the pulley. With this done I then machined an adaptor to fit the register on the drive pulley and the Index/adaptor of the Lever Operated Closer. The adaptor was drilled to suit the fitting holes in the lever Operated Closer adaptor and the hole centres transferred to the Rapid Turn drive pulley which were then drilled and tapped M^ to suit the mounting cap screws. I then cut the draw tube to length and machined a new thread in the end of it to suit the collets.

Here are the results

Edited By Bob Rodgerson on 14/01/2018 09:48:07

Edited By Bob Rodgerson on 14/01/2018 09:48:52

Bob Rodgerson.