As far as parting off under power goes, I have always been reluctant to & always used manual when I’ve had to, mainly due to lack of confidence & not have the correct set up. I think I have now resolved my issue; I needed to have some large washers to replace the ones holding my vice to the mill table as the present ones are the large penny / patch ones, backed up with a couple of 10 mm standard washers. I decided to put my Hemmingway kit (usual disclaimer) constructed rear tool post to the test & part off some 30mm dia. BMS that I had drilled 10.5mm, I have used this tool post before but only on brass as a test after I built it.

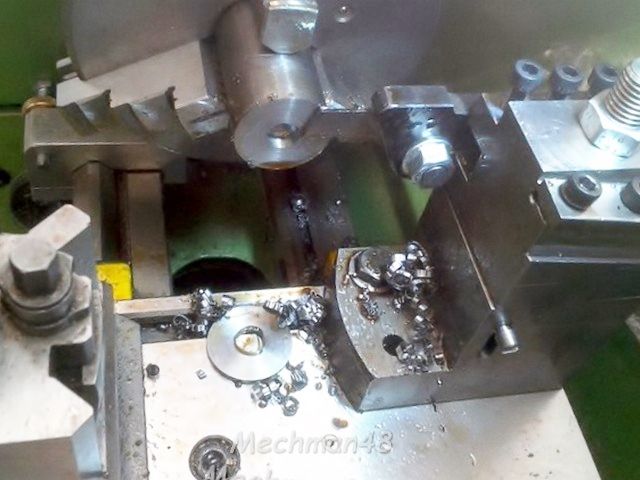

Having set it up true& checked centre height I proceeded to part of … manually first, the cut went ok provided I applied plenty of neat cutting oil with one hand & trying to maintain constant feed rate with the other, (really could do with 3 hands here). Two washers were completed ok but the finish wasn’t the best so in for a penny etc. I went for the PXF… I locked everything down & my speed was set at 200 rpm (arbitrarily) & the federate was as set originally from day one…. .03mm per rev. the lowest setting on the machine chart. I set the leadscrew to run in reverse, actuated the crossfeed lever & set to, the cutting action was very smooth but it soon told me when it started to get tight, I could discern the swarf trying to bind in the cut, this was remedied quickly by applying a constant supply of neat cutting oil, by brush (I don’t have a constant supply set up … yet) which made cutting a lot easier. There wasn’t any noticeable loading on the motor & it did the cut well, which has done wonders for my confidence now, also the finish was much better. Still goes to show, you can teach an old dog new tricks!

The blade used was HSS 3/32, I also have a small ¼” HSS tool steel cutter that I have ground to 1mm thick blade for small parting off which I have used without any fear. I am tempted to get one of the indexible insert type parting tools, complete with holder but it’s a bit pricey at £32 (RDG) but do I do enough parting off to warrant the expense… hmmm?

First attempt at PXF parting off in years…

The remaining rag shows parallel cutting…

The two on the left were manual feed, bit of a rough finish, (the dark one is 'cos the flash didn't reach it, it's not heat discolouration)) the one on right is PXF parted off & much better finish…

I shall not now be wary of using PXF with the rear tool post on steel.

George

JasonB.

JasonB.

however as I'm sure you will have been frustrated by the poor pictures on the vendors site, and have searched a lot for relevant information I suggest when you do post some pictures you a) caption them including the lathe name, and b) post pictures that fill in the details you couldn't find when searching.

however as I'm sure you will have been frustrated by the poor pictures on the vendors site, and have searched a lot for relevant information I suggest when you do post some pictures you a) caption them including the lathe name, and b) post pictures that fill in the details you couldn't find when searching.