lathe and mill motor control

lathe and mill motor control

- This topic has 7 replies, 7 voices, and was last updated 7 January 2024 at 10:10 by

Mike Hurley.

Viewing 8 posts - 1 through 8 (of 8 total)

Viewing 8 posts - 1 through 8 (of 8 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

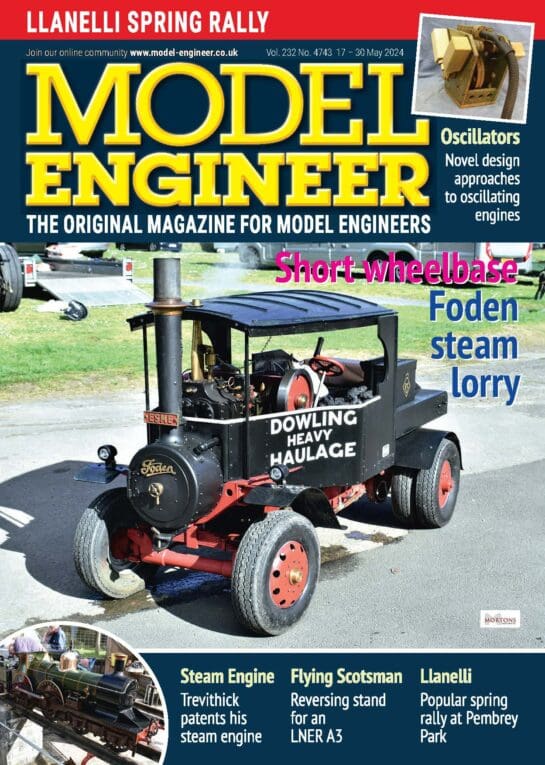

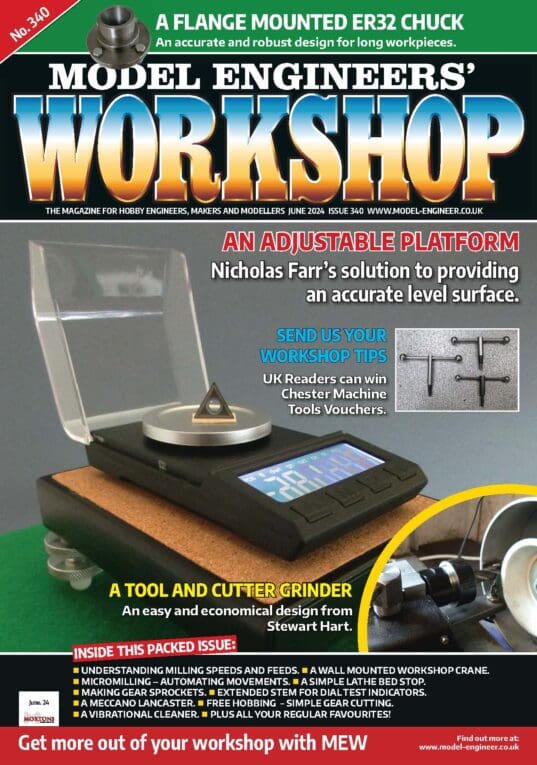

Latest Issues

Latest Replies

- Unimat3 vs. Sherline lathes

- Mini closed cycle steam engine, possible?

- Drill Grinding Jig

- Hello from France

- CAD print output. ‘white’ text on a black dial face. (silhouette?)

- Which collet

- Advice sought on good make of lathe and milling machine

- Warco WM250V Cross Slide Nuts

- Bed for 6040 CNC?

- DRO Origin Setting