…

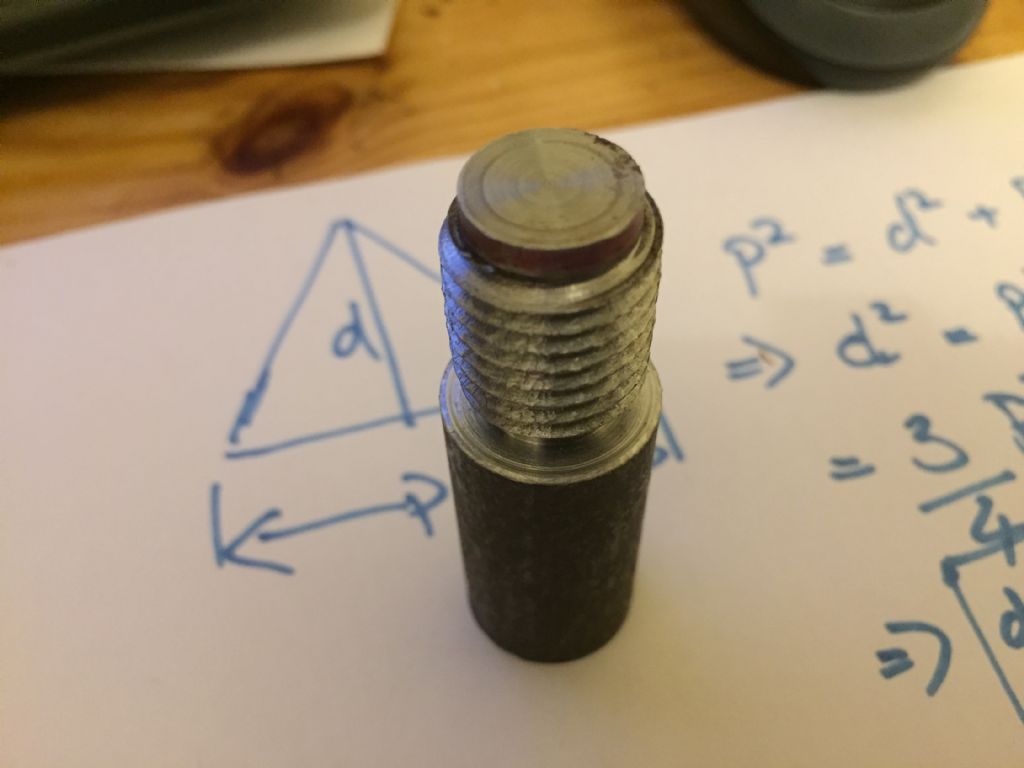

radial DOC 0.4mm for the first cut, then 0.2 , then 0.1 down to final depth. All straight feed, no topslide angling.

Try lighter cuts. Not always good with carbide tips, I know. But worth trying a series of .02mm cuts to finish off. And its common to make several passes at the final depth setting without adding any extra cut depth. This allows any spring in the tool and job to be "worked out" and has a sort of polishing effect sometimes.

Also when you get to the theoretical correct thread depth, you could try advancing the topslide by .02 or so so the tool takes a light clean-up cut down one cheek of the thread. Then reset the topslide back to Minus .02 from the original position (done by winding the handle back past the backlash and bringing the dial back up to just before the original setting). This will clean up the trailing flank of the thread.

Also, while you are cutting the main part of the thread, instead of offsetting the topslide to 29 degrees etc, you can leave it in the normal position and for every movement of the cross slide inwards, advance the topslide half that amount. EG if you take a 0.2mm deep cut, advance the topslide by 0.1mm. This moves the tool bit point in a path almost at 29 degrees and has the same effect as angling the topslide. With the advantage you can perform the previously described clean up cuts along each individual flank at the end of the operation.

Chuck up some scrap bar and have a good play around and practice with it before you go on to make your actual part.

And no matter how good your screwcutting, expect to have to run a file down the tops of the threads to clean up the inevitable burr. (Doubtless there will be magicians out there who can turn a thread without doing this but they are not mere mortals like us.)

I don't know about the rpm for carbide screw cutting tips. I use a brazed carbide 60 degree screw cutting tool on my old Drummond Flagellator at about 100 rpm and it seems to work rather well. Not sure if the inserts can be run that slow? The brazed tool has a sharp ground edge, which not all inserts have.

Robin Graham.