Posted by Derek Lane on 11/11/2021 15:35:44:

Posted by Dave Halford on 11/11/2021 14:57:02:

Are they all different types?

It is THIS set so different cutters.

I've got the same set I think. It's best for heavy cutting rather than fine work. The inserts and holders work best on a powerful, stiff machine. 5HP wouldn't phase them!

Generally, carbide inserts are shaped to cut on all the available edges. This is unlike HSS, which have to be ground to make an edge. Edges are unlikely to be used along their full length because Inserts are limited by other factors.

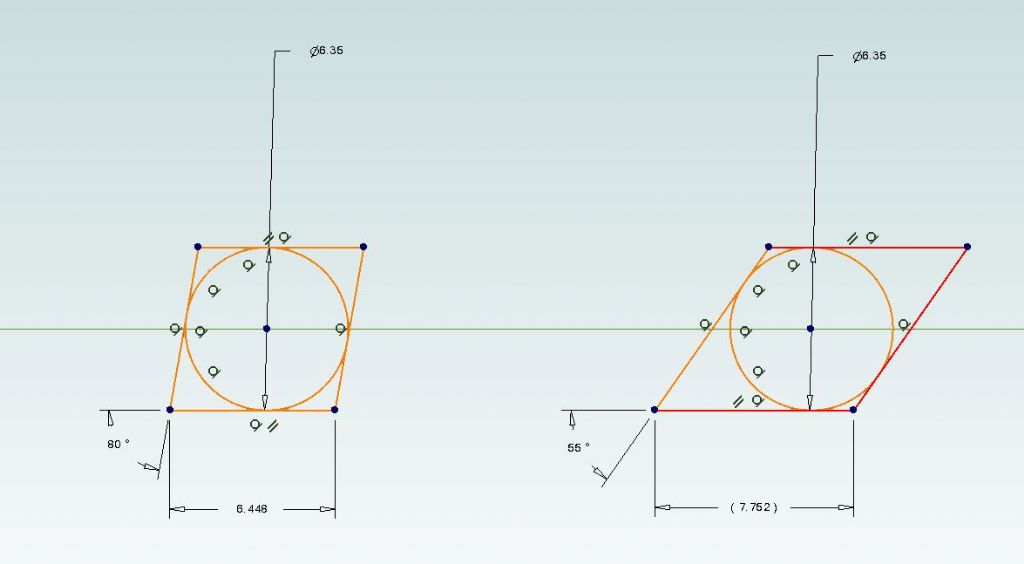

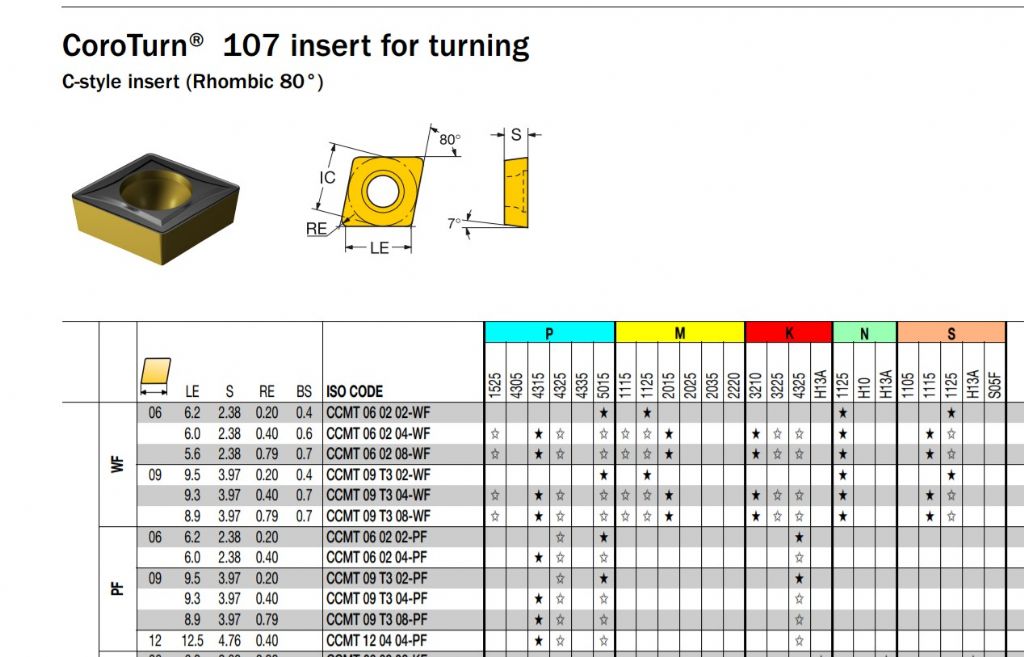

Your square inserts cut at the point and could cut all along each edge except the tool gets in the way and/or the lathe doesn't have enough power and rigidity to take a cut that deep. In practice cutting is limited to a few millimetres each side of the point; I rarely take cuts more than 2mm deep. Excellent roughing tool and it does chamfers and plunge Vs.

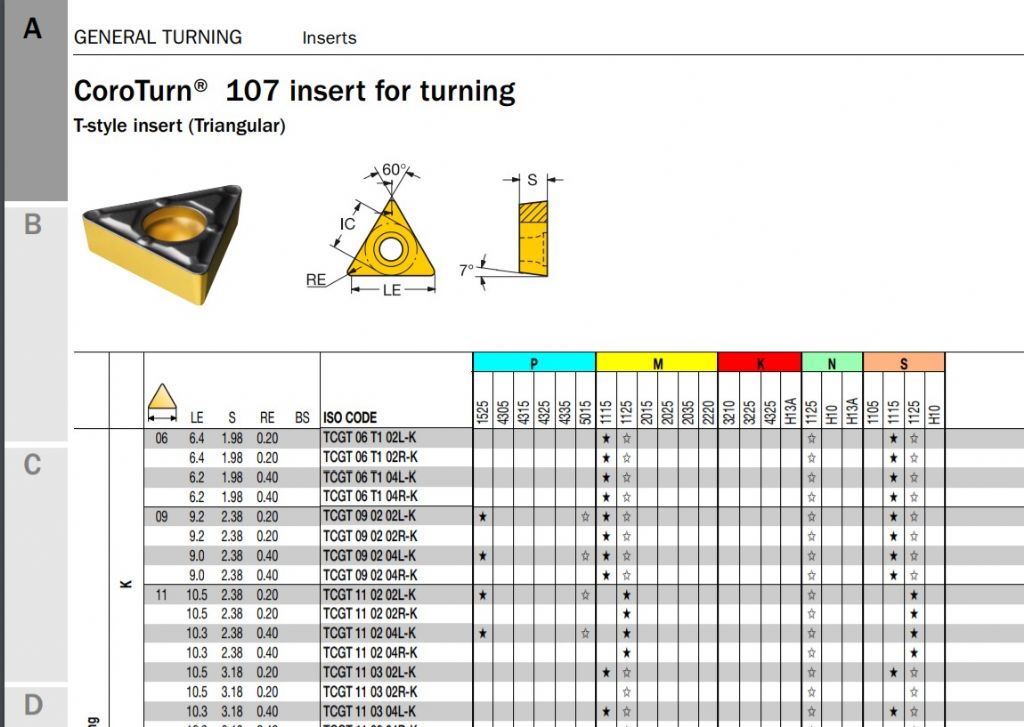

The straight triangular inserts can cut along the entire edge, which is occasionally useful. Otherwise it's a good roughing tool, but I wouldn't normally use the whole cutting edge to take deep cuts. (You can – experiment if it seems useful!)

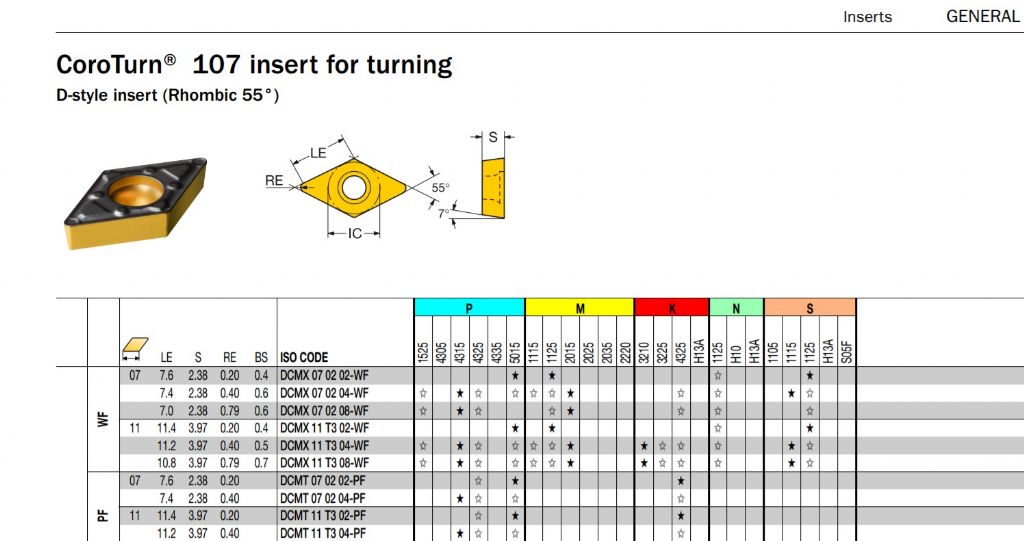

The triangular inserts with a bump in the middle cut at the point and on the straight bit. I find this shape most useful because it cuts well and can get into corners to make a nice right angle.

No round insert in the set unfortunately. They're used for forming, but the entire edge of a round insert will cut. If the edge is chipped, the insert can be rotated slightly to present fresh edge. Likewise square inserts can be rotated 4 times to present a new point and edge, triangular types 3 times.

For fine work, I go down a holder size and use smaller inserts, especially the sharp non-ferrous types, which I cheerfully use on steel. Just be careful not to bump the points.

Dave

Dalboy.