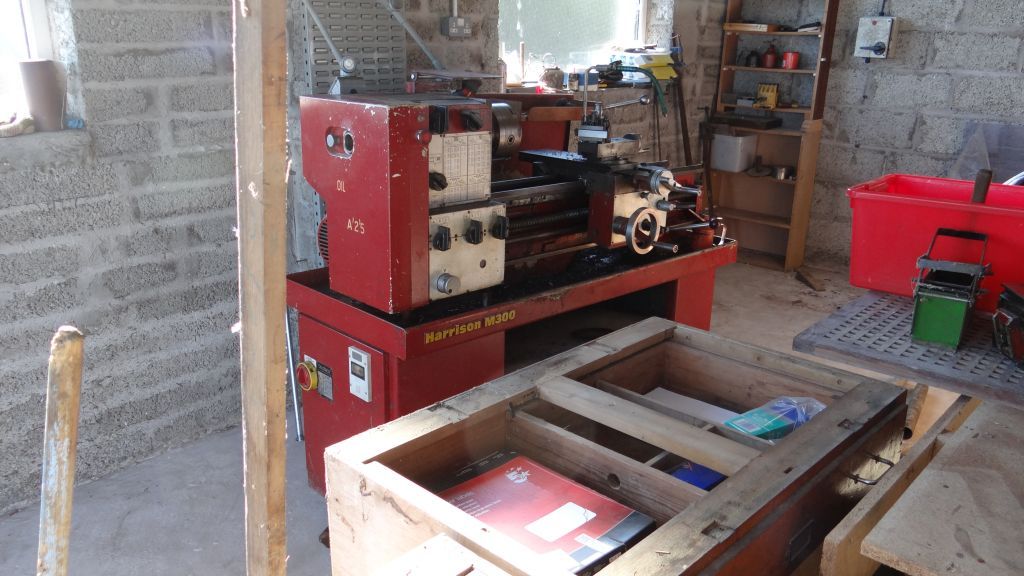

Having recovered from a bug that flattened me a couple of weeks ago, I set out to make a new cog for the DTI on my Harrison M300 (Imperial) lathe using the invaluable information provided by John Brookes of the Harrison Users Group.

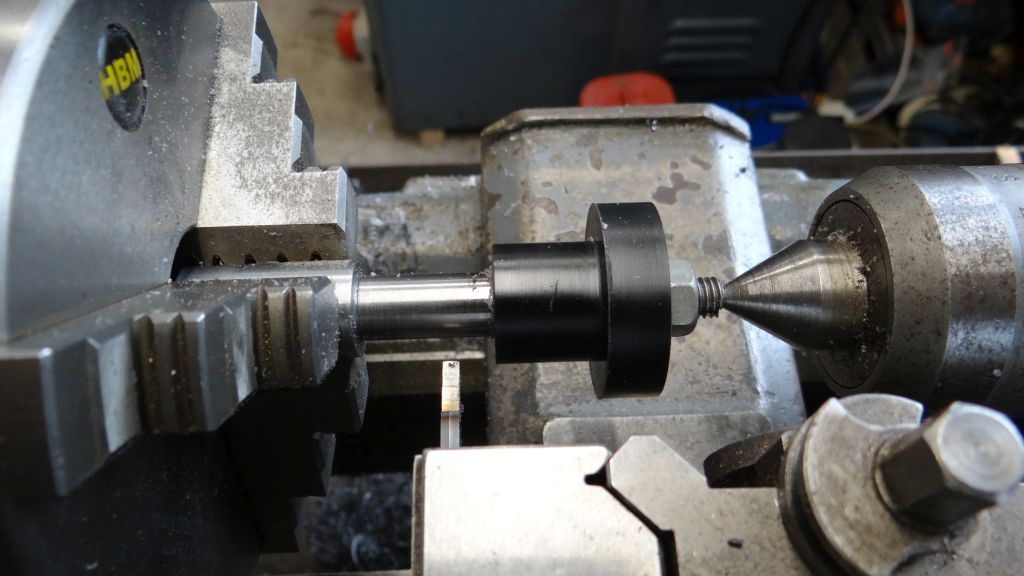

The first attempt was a bit of a fiasco but served its purpose as I realised that it would be much simpler to make a single component using the DTI spindle as a mandrel rather than the original separate collar and cog.

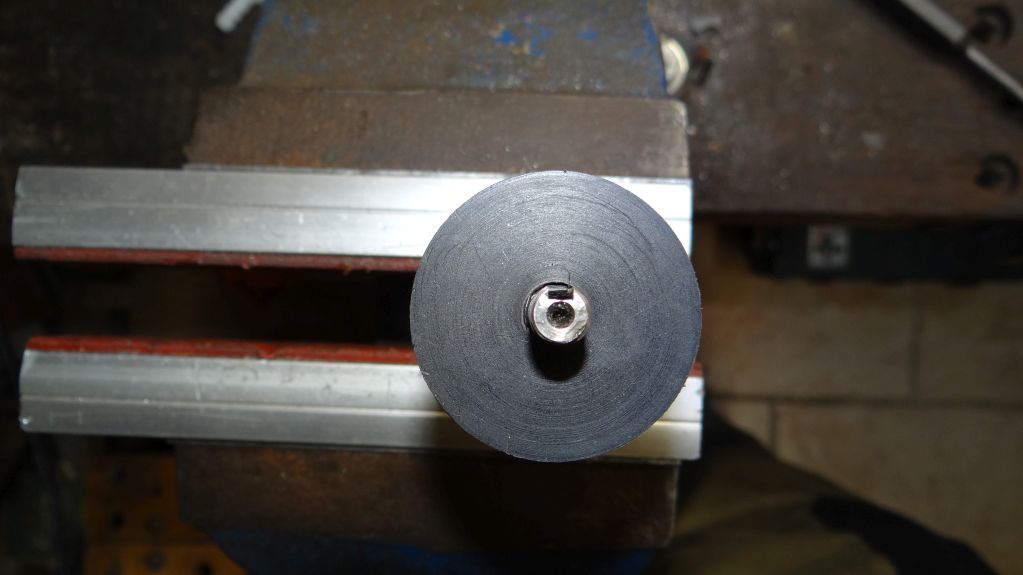

A suitable length of 40mm diameter Delrin was cut and bored 3/8" to fit the spindle. The keyway in the spindle is 1/8" so, using a piece of 1/8" square tool steel ground to a cutting chamfer at one end, I was able to press the blank onto the spindle cutting the way in the Delrin blank as it went.

The outside diameter was turned down to 35.5mm and the shoulder to 7/8" dia x 3/4" long in accordance with John's information

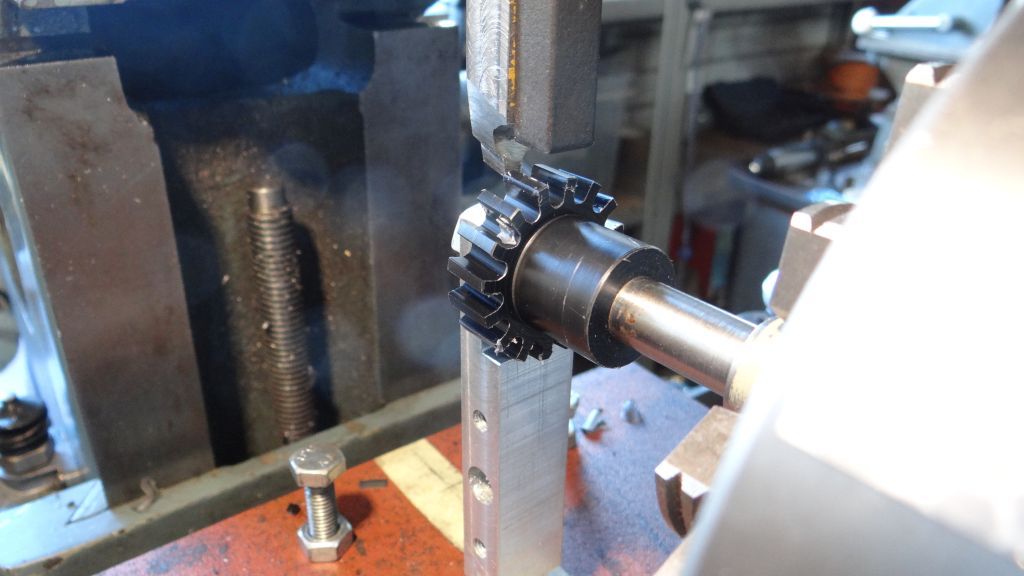

An extension plate was mounted on the shaper box to provide enough length to mount the dividing head, chuck and spindle. The dividing head was angled at approximately 5deg which was what I had measured roughly from the leadscrew

The chuck was then transferred from the lathe to the dividing head and a jack made from a scrap piece of aluminium was mounted to support the outer end of the spindle

I had no information about the profile required for the cutter, but using John's photographs and a bit of "guesstimation", I ground a shaping tool to what I thought would do, given the undemanding nature of the profile

So, with fingers crossed, the first cut was made to the depth given by John

This went well, so, with great concentration, the rest ot the cuts were made

It is always a relief to complete the last cut without any disasters, especially when you arrive back to where you started!

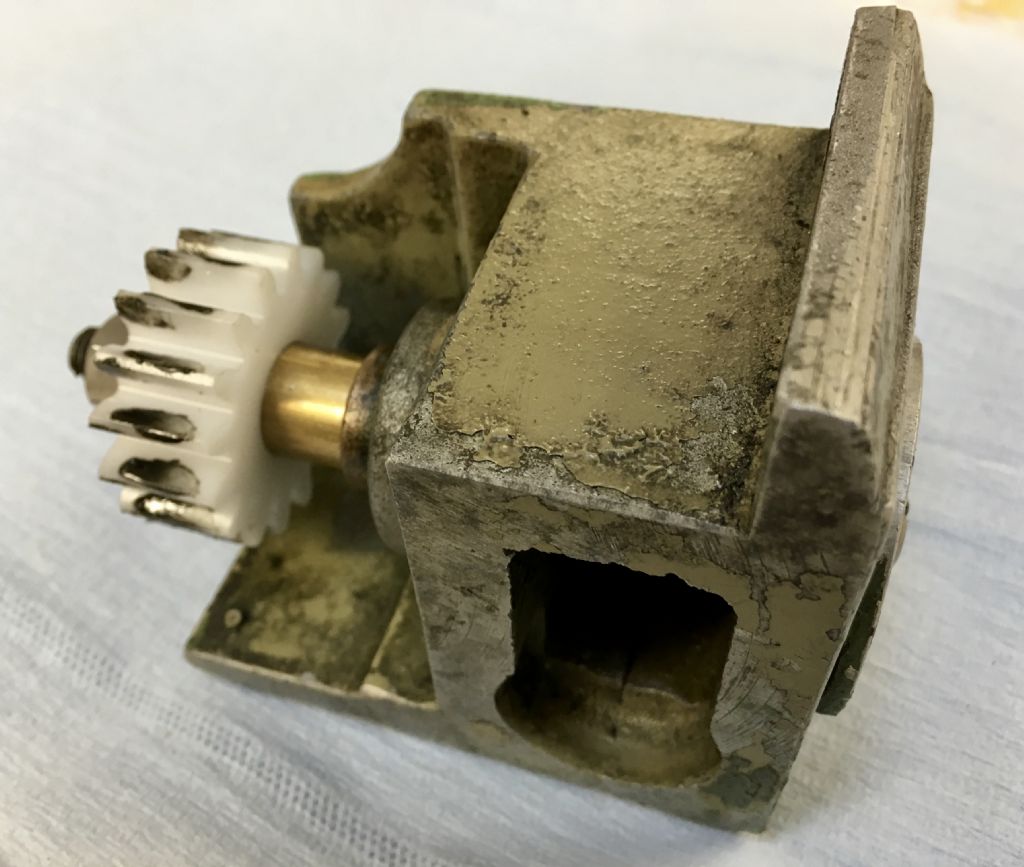

The finished article

And the bonus is – it works!

With many thanks to John and all the others who responded to my request for information

Jon.