Hello Again,

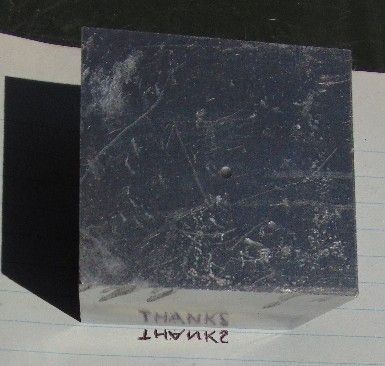

Yeeha ! I got a reflection in Aluminium ! Chuffed !!!

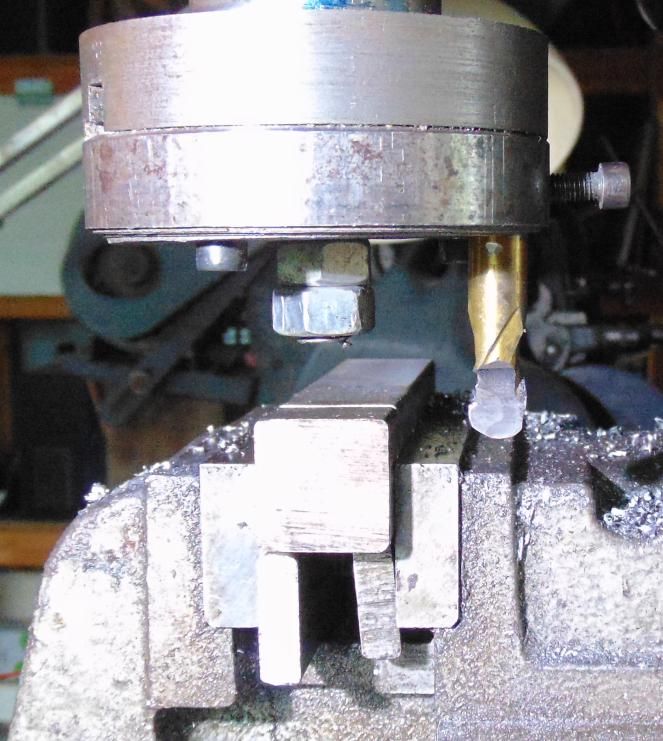

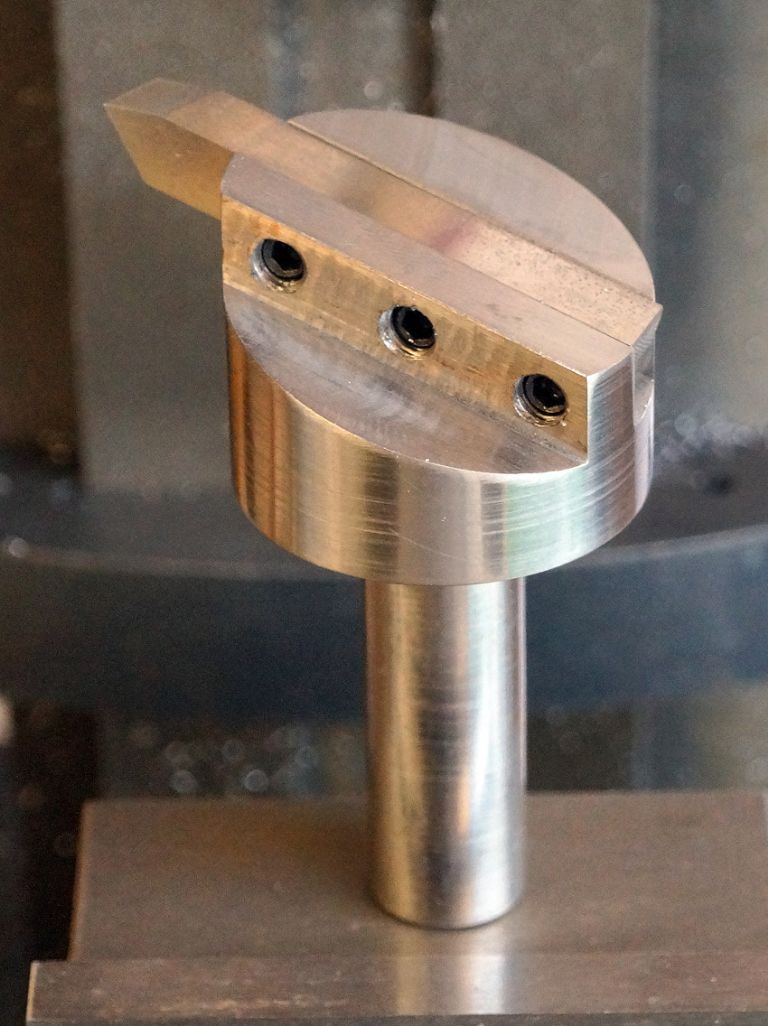

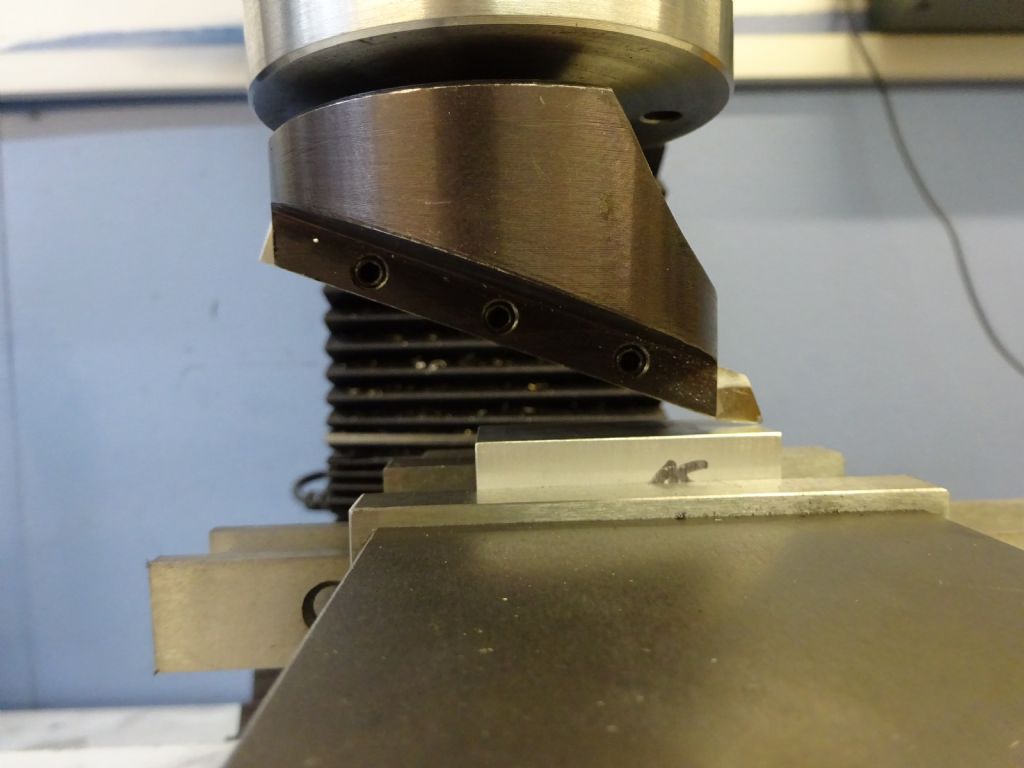

Rong Fu 30 Round Column Mill 2HP Motor

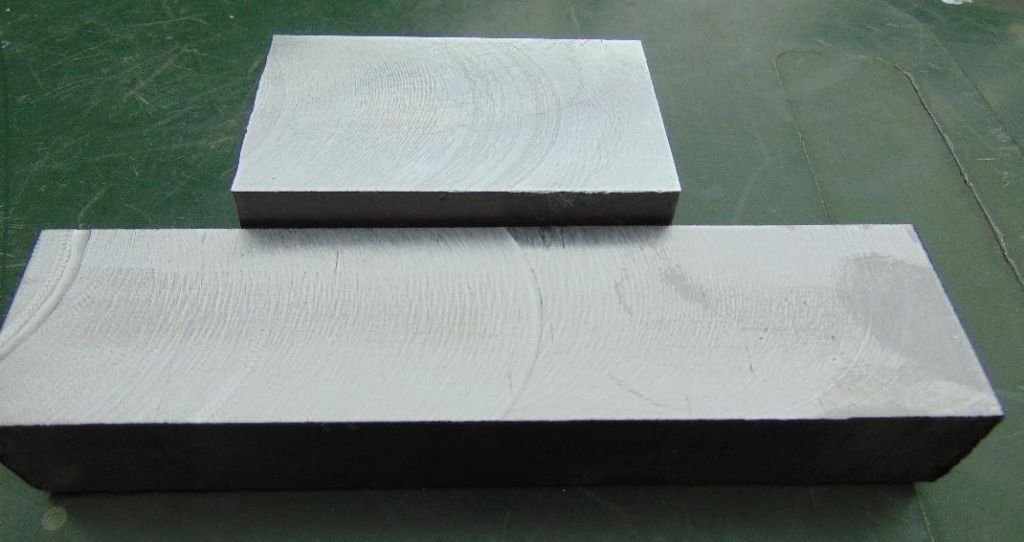

Aluminium Block Unknown type of Aluminium, Plenty of WD40 whilst cutting.

400 rpm approx 2.5"diameter cut 8 seconds per 2.5mm so = 80 seconds/inch = 0.75" per minute approx 0.001" doc – thats extremely slow feeds/speeds comparted to Jason's . WIll do some variations to better understand things.

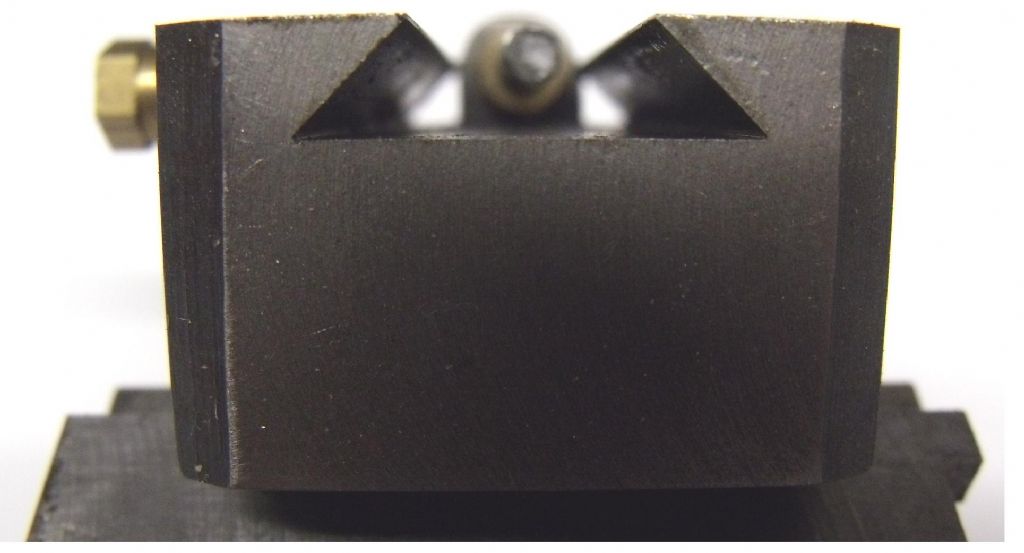

Shortened the stickout to approx 0.5" (and yes I was getting chatter on the long stickout and shorter radius curve on tool – some interesting patterns & could hear it squeal). Need to do something about those 2 nuts before shortening stickout further.

Re-ground the tool to a much flatter curve as suggested by Jason.

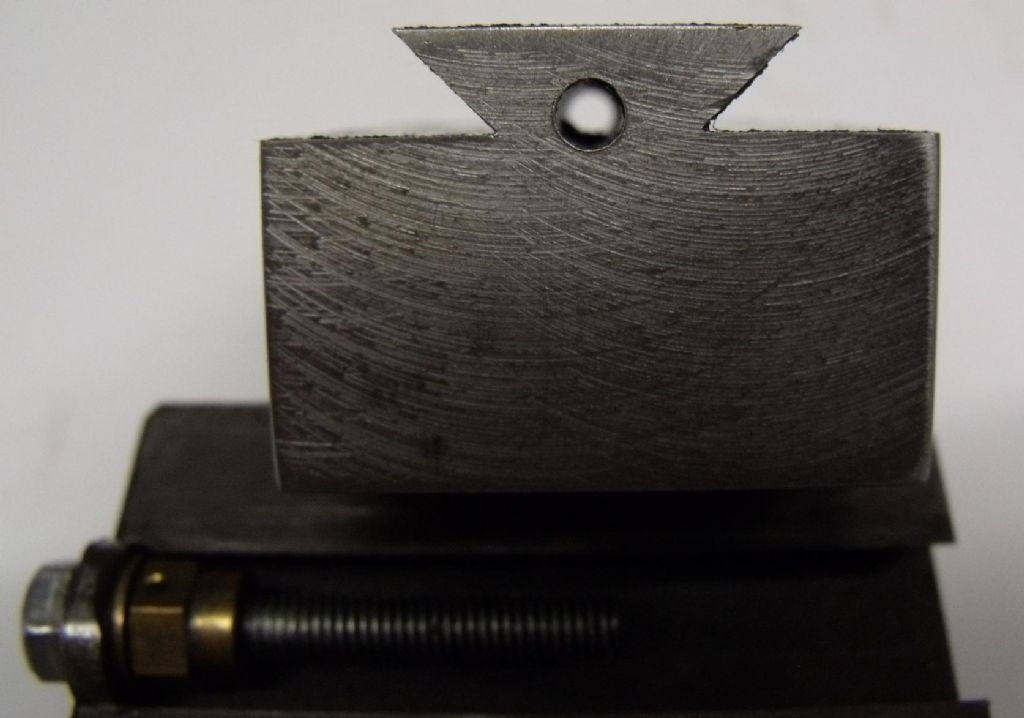

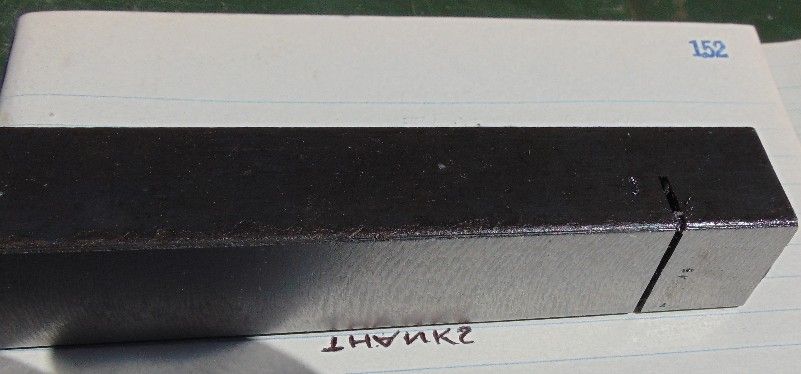

Wasn't able to get as nice a finish on black bar – although it looks horribly corrugated it is actually quite smooth to the touch – cannot feel the corrugations with fingertips – do the corrugations indicate I am feeding too quickly ? Haven't quite got a reflection on the black bar.

Nevertheless, this is the best finish I have ever achieved on my mill with both black bar and aluminium. Think I just need to play around a bit and better understand speeds feeds and grinds.

Will try the "conventional" flycutter next.

Many thanks for all of the help/tips/photos in this thread.

Hey Ron Laden,

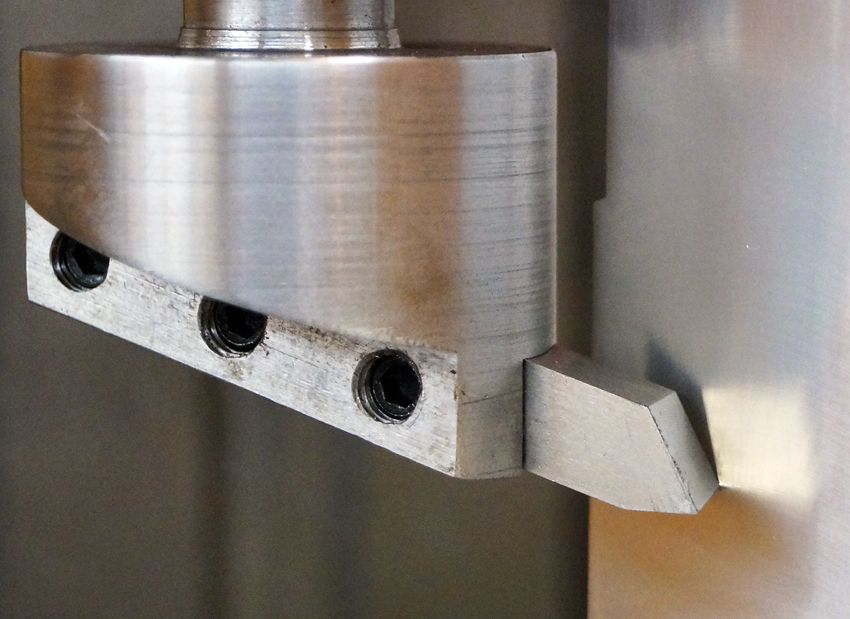

I cannot figure out which part of your cutter contacts the work and cuts it, your bottom edge looks almost horizontal to me.

Thanks Again,

Bill

Ron Laden.