Chaps, it was not my intention to stir the pot so badly…I am certainly not upset with anyone here!

Perhaps I do share some of the blame however- I indicated I am trying to measure the displacement, when I suppose what is really needed is to find a way to show that the detection 'accuracy' is 'good enough' to within limits so small that the actual value of the deflection does not matter. In other words, for a edge detection probe, one would probably be safe to assume a deflection of less than 0.01mm is acceptable, since we rarely work to better than that anyway. But if I can achieve better than 0.005mm, then that would be really good. If the actual value lies somewhere between 0.001mm and 0.008mm, it is still really good, but not definitive – but perhaps that does not matter to be able to use the probe definitively.

So my absolute requirement statement was poorly put and I apologise..

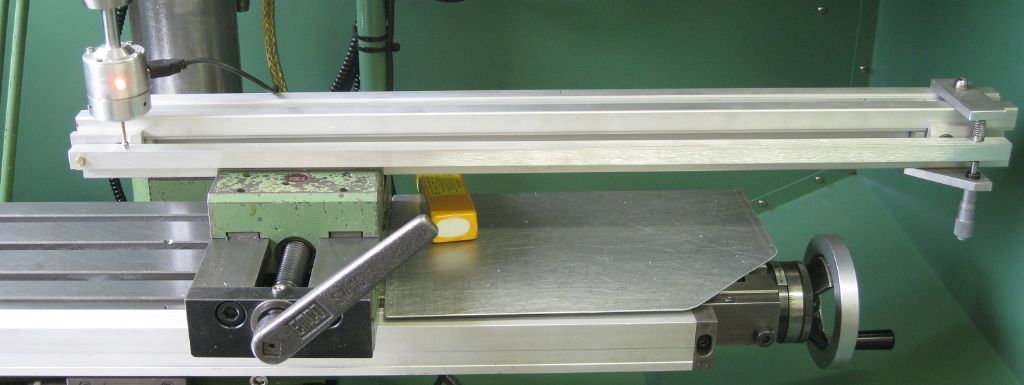

That said, I went and made a mechanical 'magnifier' – a long arm, pivot one end, micrometer at 600mm from the pivot, and my probe at 30mm from the pivot, so a 1:20 reduction of Micrometer anvil motion. This is not perfect of course, working in an arc, etc, so the linear movement at 30 mm is not true….but its good enough!

Set up in the mill and tested with a 0.01mm indicator, and then a 0.001mm indicator ( of dubious nature..)

Then I set the probe in the mill and tested that for contact – I do believe my contact displacement is less than 0.0005mm, maybe even 0.0002mm…Judge for yourselves..

The device in the mill, turned 90deg to check Z axis of the probe:

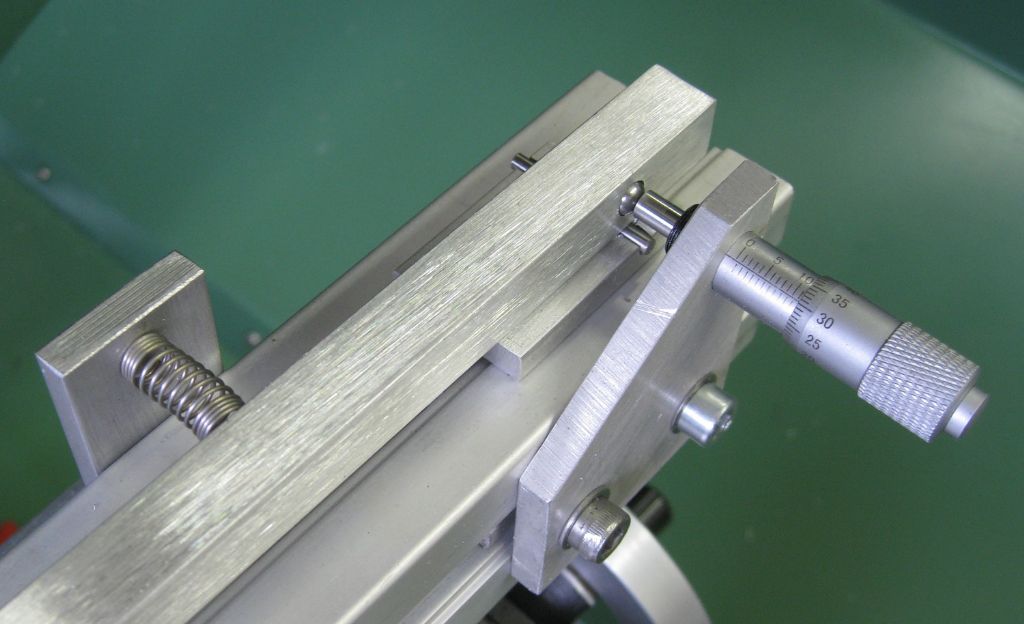

Mic end:

Pivot end:

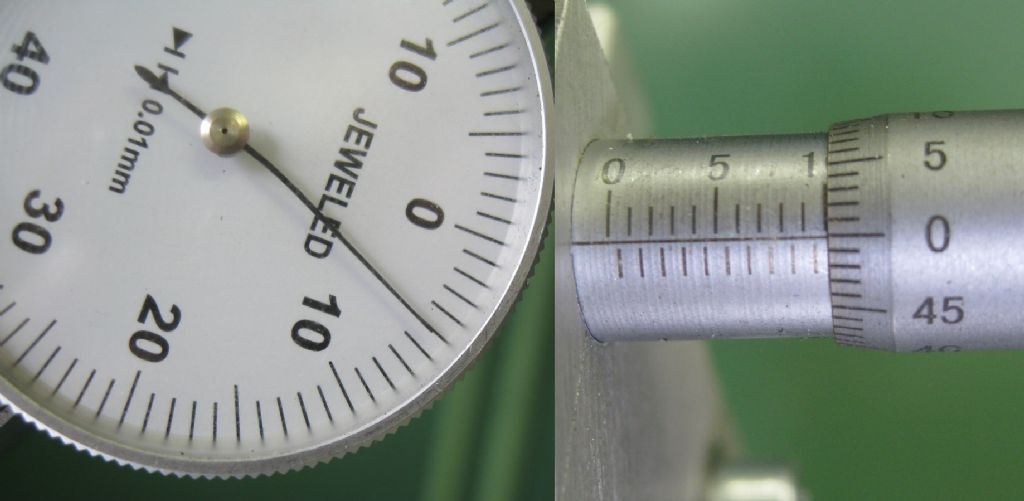

Using a 0.01mm indicator-below: (note, arm multiplier = 20)

Fist row – Dial and Mic at Zero.

Second row – Mic plus 5div x 0.01mm = 0.05mm div 20 = 0.0025mm at indicator

Third row – Mic 25 divisions = 25 x 0.01mm = 0.25mm div 20 = 0.0125mm at indicator.

Dial appears to be under-indicating by 0.002mm maybe?

Mic moved in 1mm, div 20 = 0.05mm, Dial shows 0.05mm – correlates OK.

Now using a dubious 0.001mm indicator:

First row – Dial 'zeroed' at 30, Mic zeroed at 11mm,

Second row – Mic moved plus 20div = 20 x 0.01mm = 0.2mm div 20 = 0.01mm

Dial moves from 30 to 40 = 10 div x 0.001mm = 0.01mm – correlates with Micrometer.

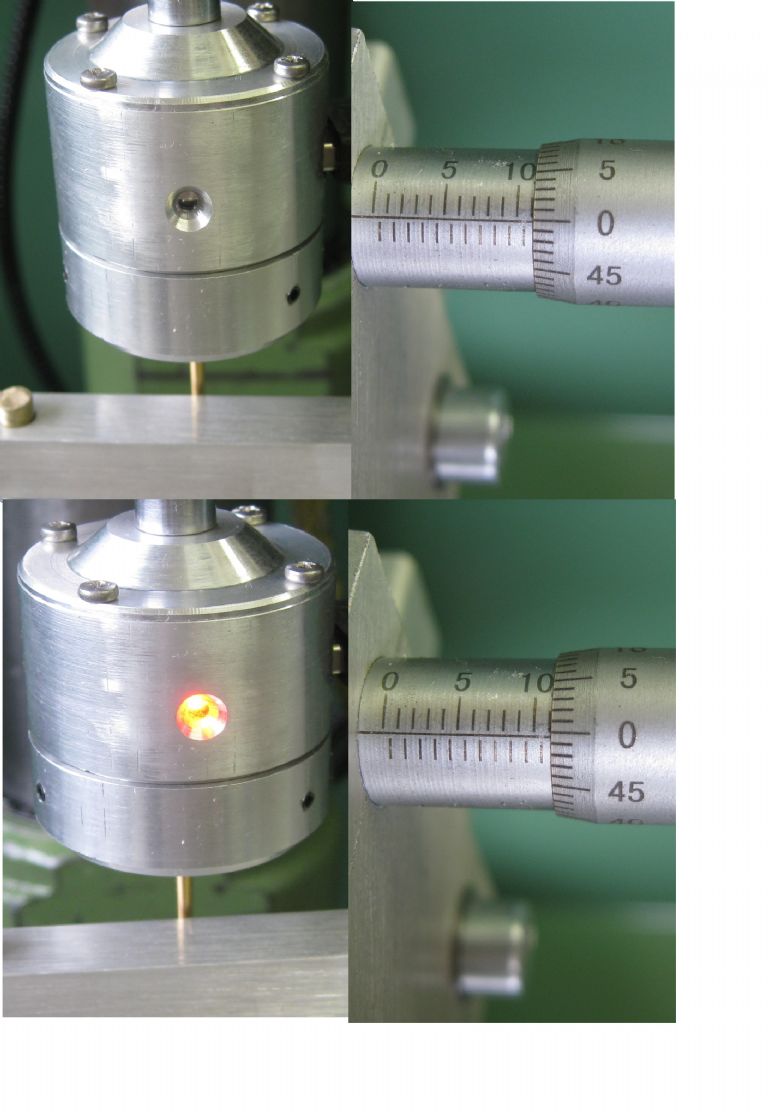

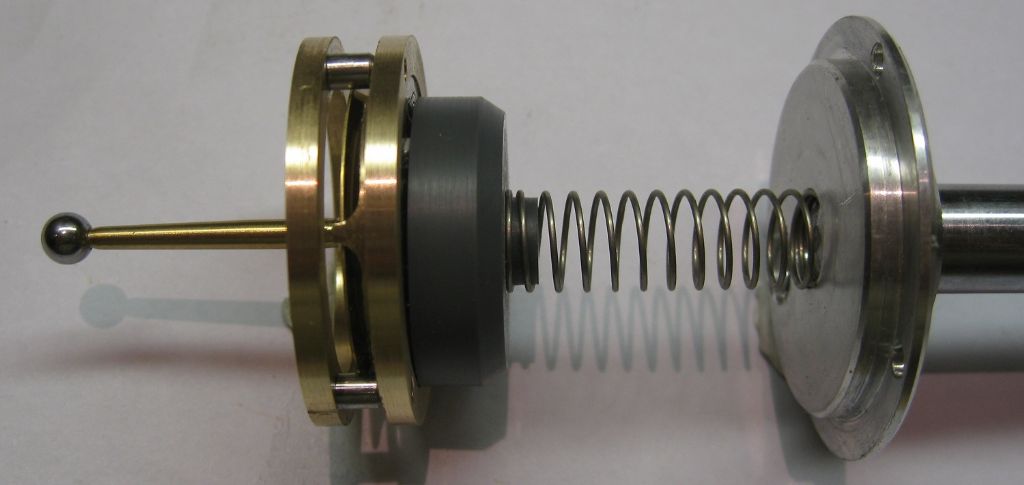

Then fitted the probe – see contact point with lever in photo below.

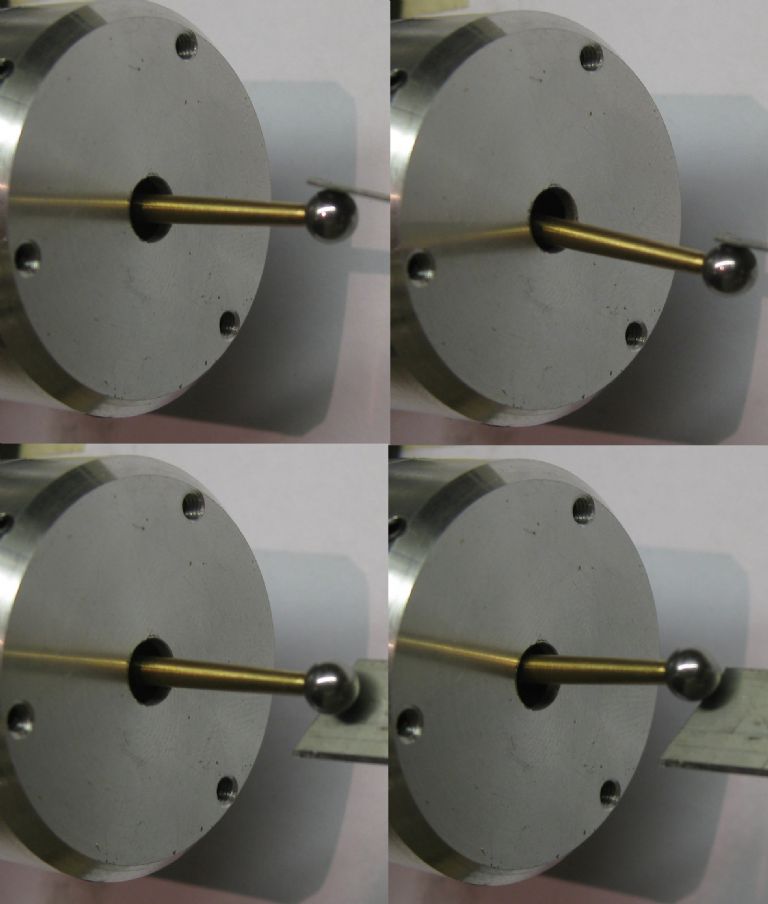

Photo below shows probe OFF, Mic = 0

Second row shows probe on – contact made, Mic = 1/2div (maybe?) = 0.01 / 2 =0.005mm

0.005mm / 20 ( lever multiplier) = 0.00025mm movement at probe tip…Believe it or not!

Similar tests were done in the Z plane with the test lever on its side – similar results obtained!

Joseph Noci 1.