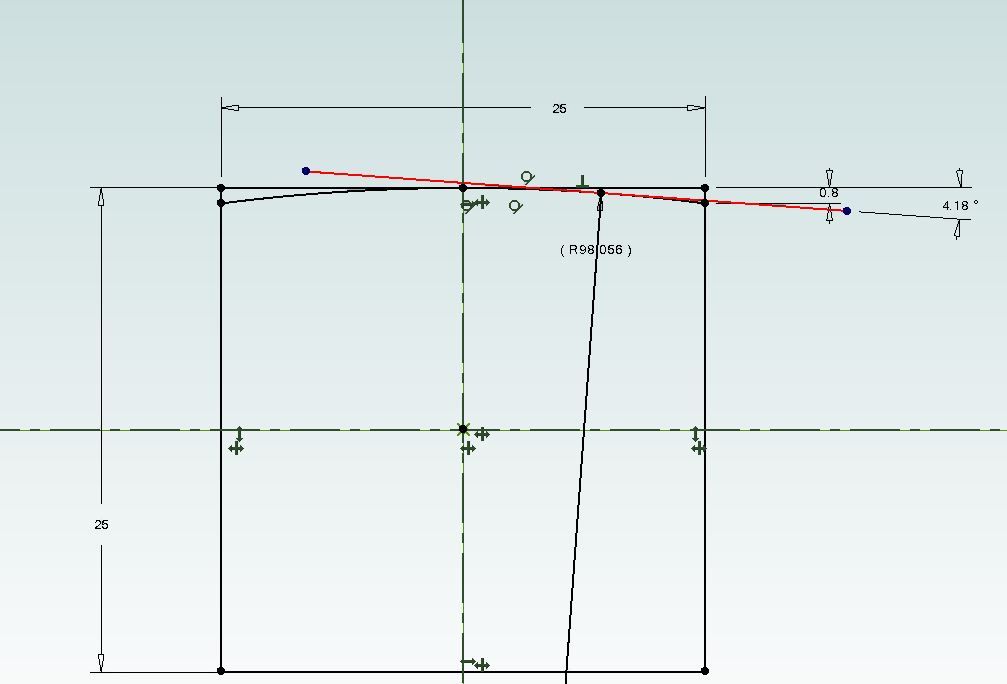

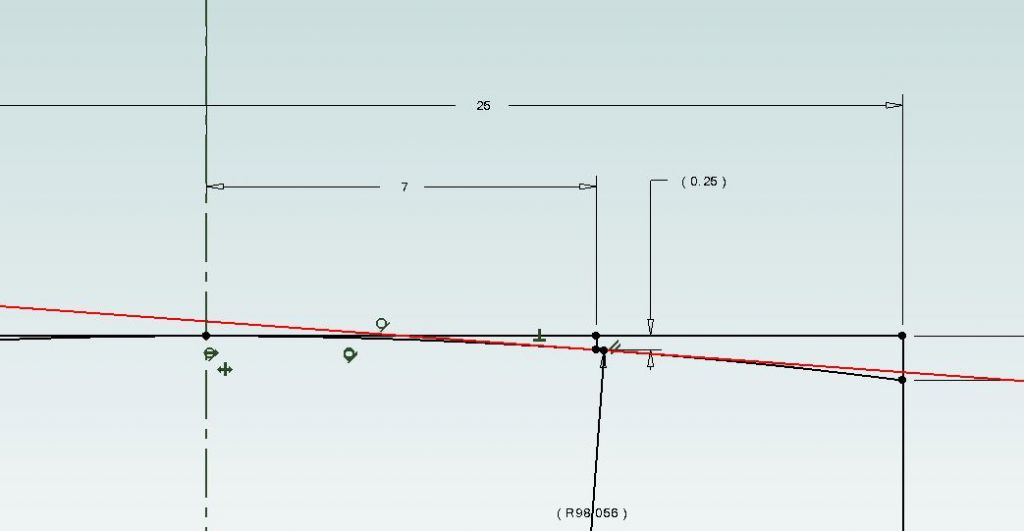

1.5 degrees looks to be not too far from correct

Kempes Engineers Year Book, in section E9/3 advises:

That pulleys should be cambered to keep the belt tracking properly, in spite of errors in alignment of shafts and lack of truth in the belt.

The profile of the pulley should be a smooth curve, or of two symmetrical two smooth curves with a flat central portion not exceeding half the width of the belt.

The advice is that where the pulleys differ markedly in size, it is good practice to leave the smaller pulley flat, and to apply camber to the larger.

Pulley width should be 15% greater than that of the belt

Maximum camber should be about 1% on diameter., or 0.2 in per foot of pulley width, whichever is the lesser.

By my calculations this suggests an angle of 1 Degree 8.7 Minutes, so I degree would probably suffice.

Flat tapers should not be used because they cause local strains in the belt, and impair contact between belt and pulley. .

For simple souls like me, the calculation shown can be made a little easier..

The square root of ( R^2 – d^2 ) involves the difference of two squares, so the calculation becomes the

Square Root of (R + d ) * (R – d )

HTH

Howard

Howard Lewis.

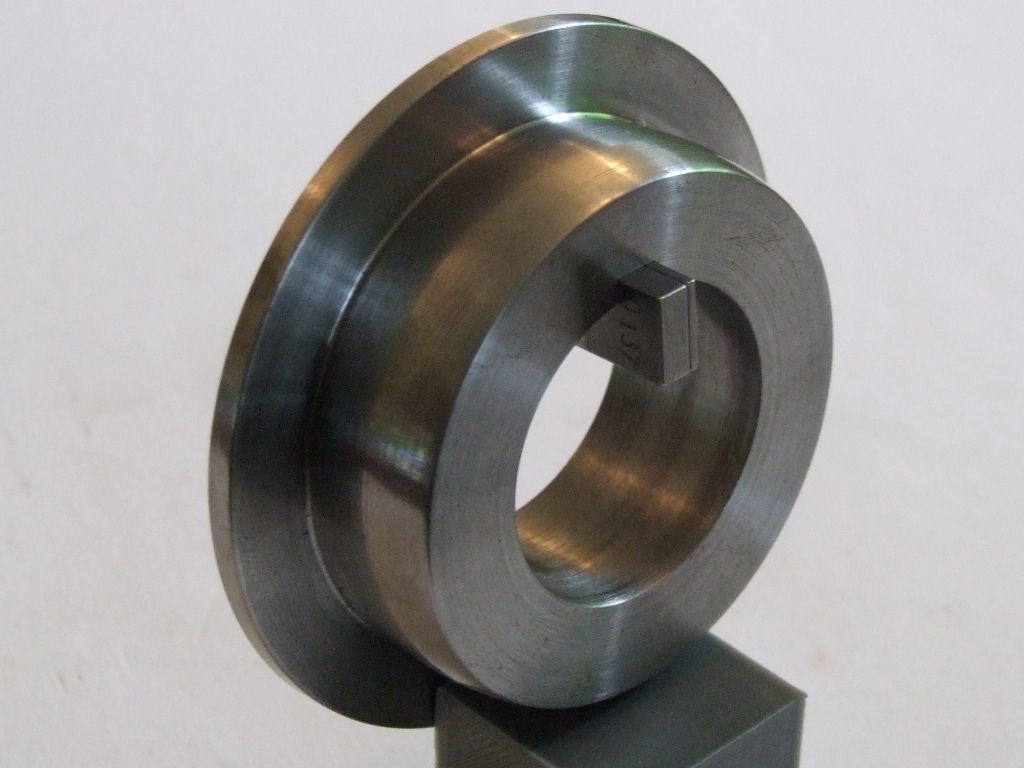

![20210304_132236[1].jpg 20210304_132236[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/890102.jpg)

![20210304_134921[1].jpg 20210304_134921[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/890107.jpg)