Thanks for all the advice. I did take some pictures to show locations, but I've left the phone upstairs during the just past yoga groaning session.

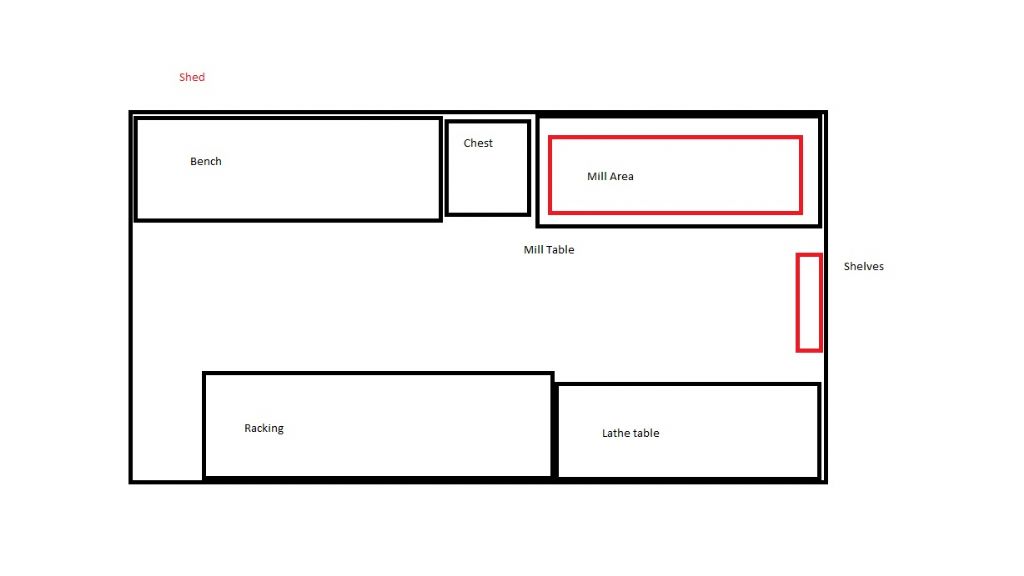

In place here is a terrible drawing

Yes. Someone who still uses paint! Shed is around 8 foot by 16 foot.

The pre-collapse shelves were on a spur uprights on 38x22mm batons. Most were 5 inch wide with the bottom two or three being 8 inches. Even with the mill table fully to the right I can easily get to the wheel. I've emulated some racks with some bits of across the shed where a rack would be timber (the offending batons!) and I simply wouldn't be able to get my hands on the wheel (without the yoga being a lot more successful than I expect, anyway!).

I couldn't see any racking less than a foot deep and although I could make some up from bits of dexion equivalent, it's not cheap and I'd rather spend my money on tooling and raw materials.

I had a chat today with my neighbour and builder who's doing his house up two doors down. As well as suggesting a solution he also gave me some materials to accomplish it (I've got 2 15 foot batons (just) sitting in my shed).

The basic idea is to glue the batons to the ribs as before, but extend them up to the wood frame above the concrete and screw the spur through the batons into the 3×3 at the top. This means I'll have a decent support at the top of the structure with continuity all the way down.

I'm still planning on roughly up the batons on the glue side (the glue stuck very well to the concrete) to help it. Also planning to get some more pressure on them whilst the glue sets, though the exact mechanism isnt' too clear to me yet.

I think this will be safe, but I will keep my ears open for creaks as I mill and be prepared to bound out of the way. Also to minimise any hard things which sit above head height.

I appreciate all the input!

Iain

Taz Meadows.