CNC build update and controller question

CNC build update and controller question

- This topic has 3 replies, 4 voices, and was last updated 6 February 2024 at 16:39 by

Michael Callaghan.

Viewing 4 posts - 1 through 4 (of 4 total)

Viewing 4 posts - 1 through 4 (of 4 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

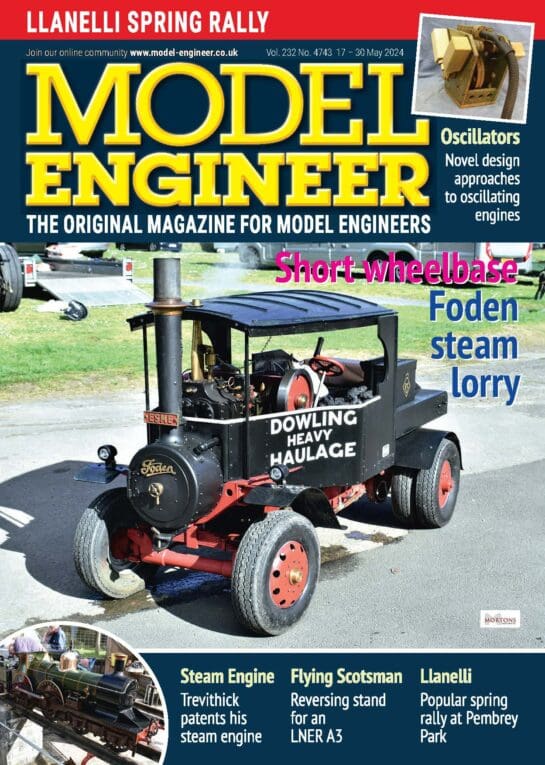

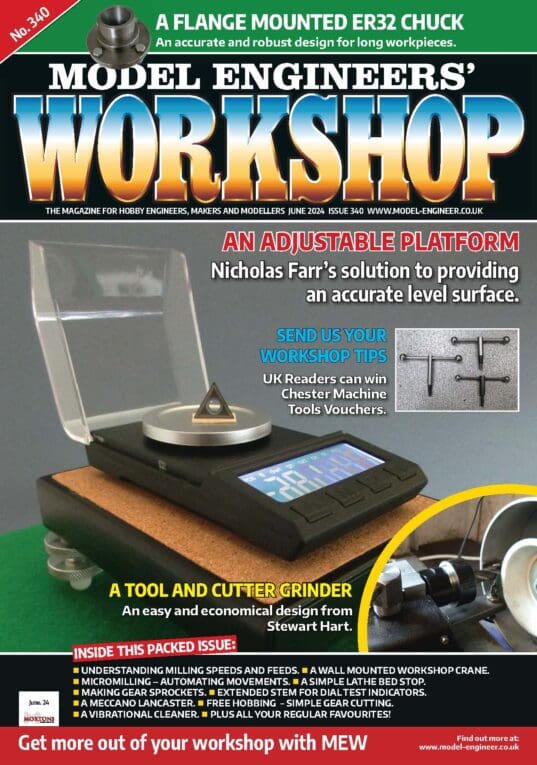

Latest Issues

Latest Replies

- New Clock Maker

- Building the James Watt micrometer (free plans)

- The Latest INDEX to Model Engineers’ Workshop

- Insert image button

- Tapping Phosphor Bronze balls

- Using Photographs In CAD?

- Diamond Wheels

- Challenge: Create an Impossible to Make Object in CAD

- ARC – Universal boring and facing head

- Stuart Twin Victoria (Princess Royal) Mill Engine