Hi Ian

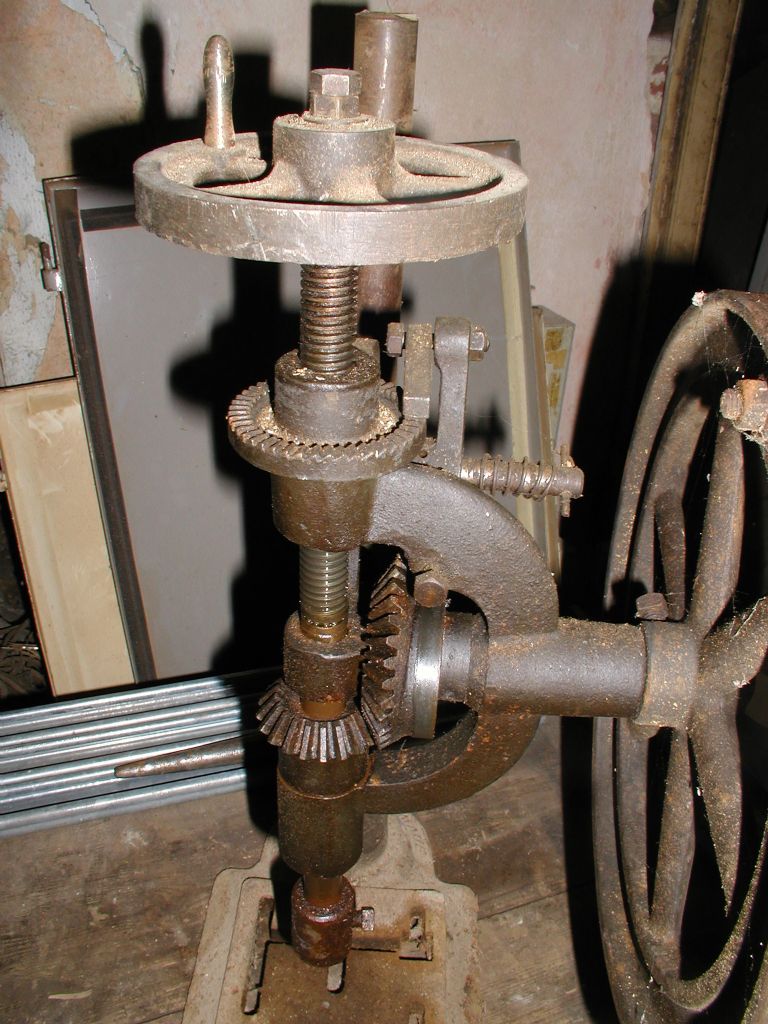

This machine is very handy once one understand the purpose of it, being able to swing 360 deg is the most advantage—will send you photo at work of my DIY stand.

Hi Nick

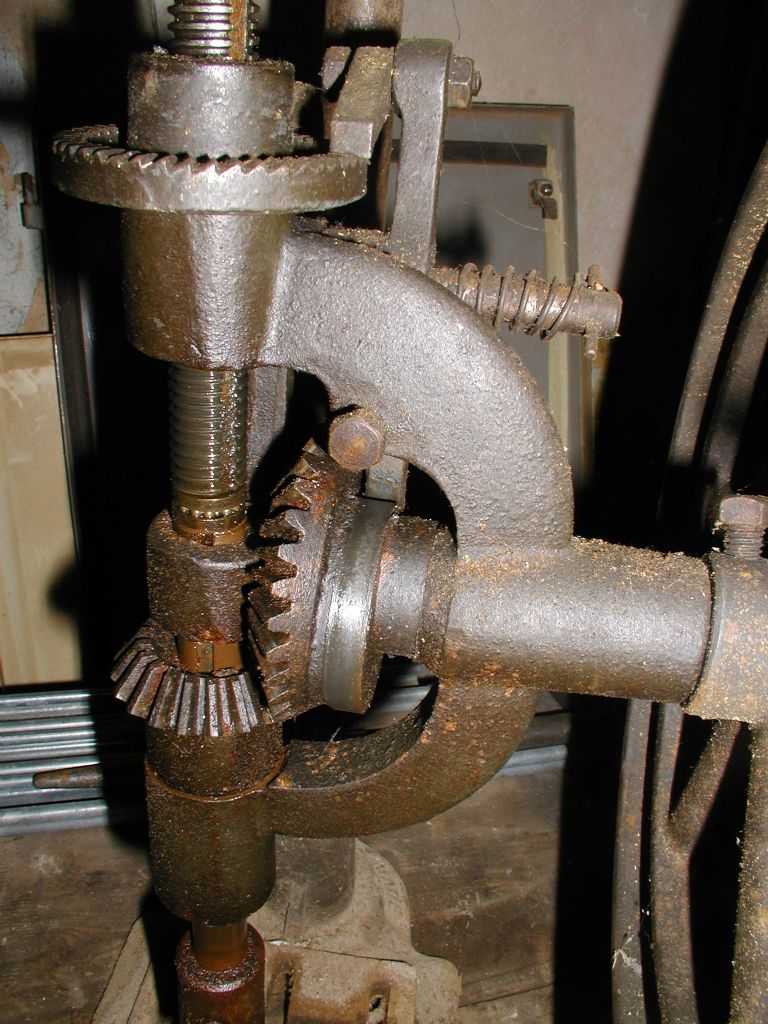

Wow! I’m so lucky to get you here! This is the machine I have in mind to build…sorry to bother you again. Ok to take photos of the gearing and auto-feeding mechanism enclosed?

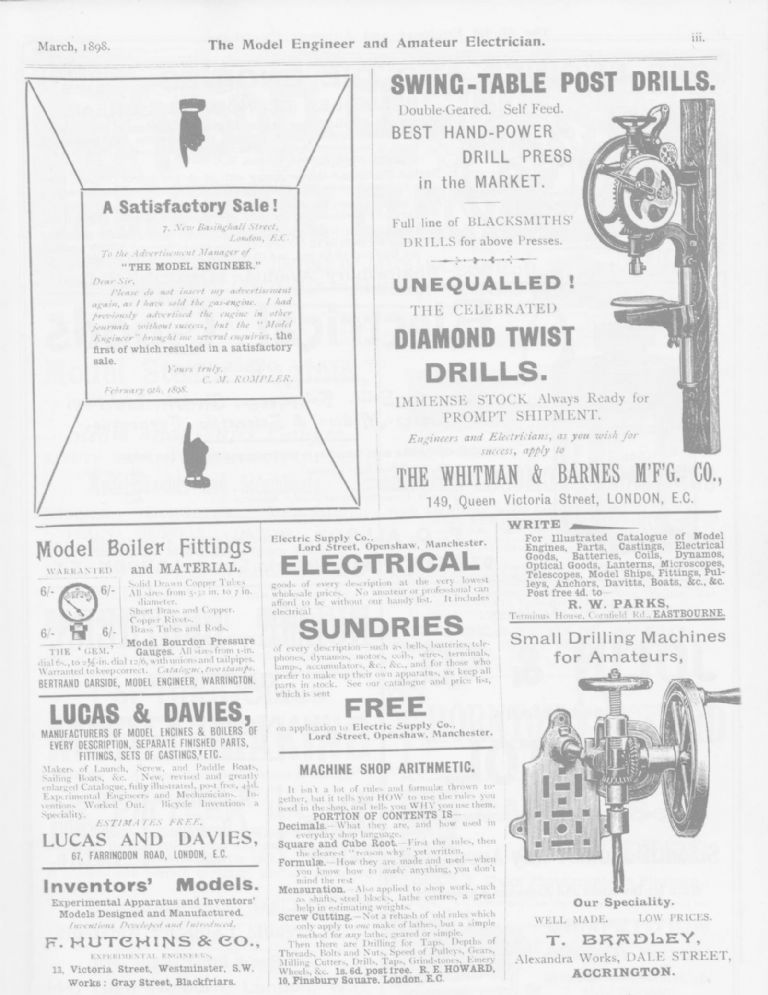

I have been using a West-Germany breast drill of 2 speeds just like yours with 2 bevel and 2 normal gears. By attaching the handle to each spindle one gets a slow and fast speed rate. This part I understand fully. This bench hand drill’s auto-feeding must be more compact than the earlier Post drill…will be interesting to study it.

I will post my stand and support of the breast drill I did which serves me well for almost 25 years for odd places to drill. Will be upgrading to a box type smiliar to yours for heavier drilling, seems getting one from India/China is not easy here. I can get those internal gears locally.

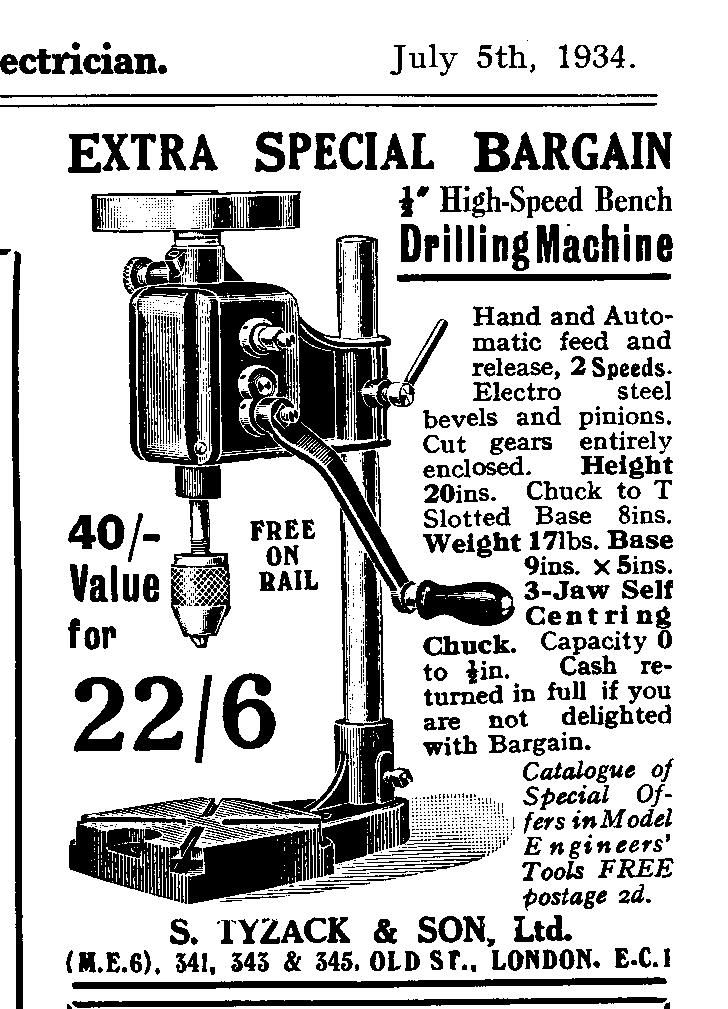

Also surprised that you kept the 1934 ads for so long

I was born 30 years later!

Nick can I have your email? You could be my teacher or engineering buddy, couldn’t find your email here…

stewan@gmail.com

Steve

Steve Wan.