Boxford VSL 500 Drive Pulley

Boxford VSL 500 Drive Pulley

- This topic has 28 replies, 9 voices, and was last updated 31 January 2022 at 23:58 by

Hopper.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Henry Milnes lathe DF4 manual

- What is Hobbymat MD65 RAL colour?

- Precision tool storage

- Motorised Adept No. 2 Shaper

- Not unexpected, but is it predictable ?

- Retractable top slide or cross slide?

- Intro – a Cambridge hobbyist

- making a 3″ saw-blade clamping washer with a tapered thickness

- Best way to straighten annealed copper tubing

- Curvimeter

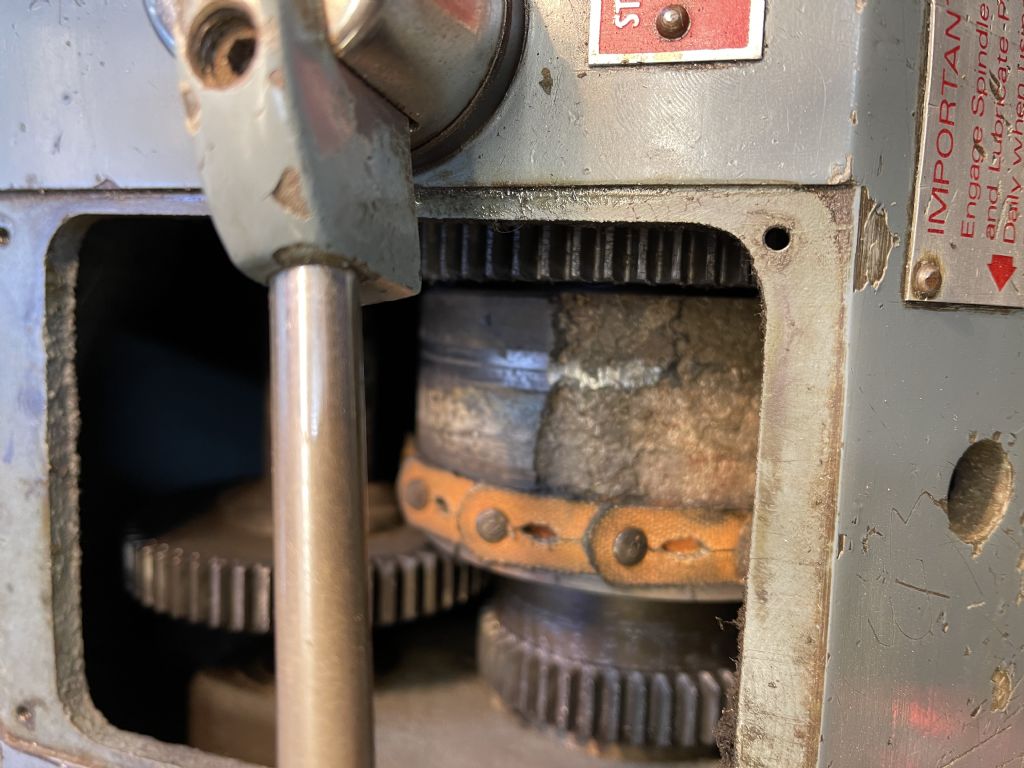

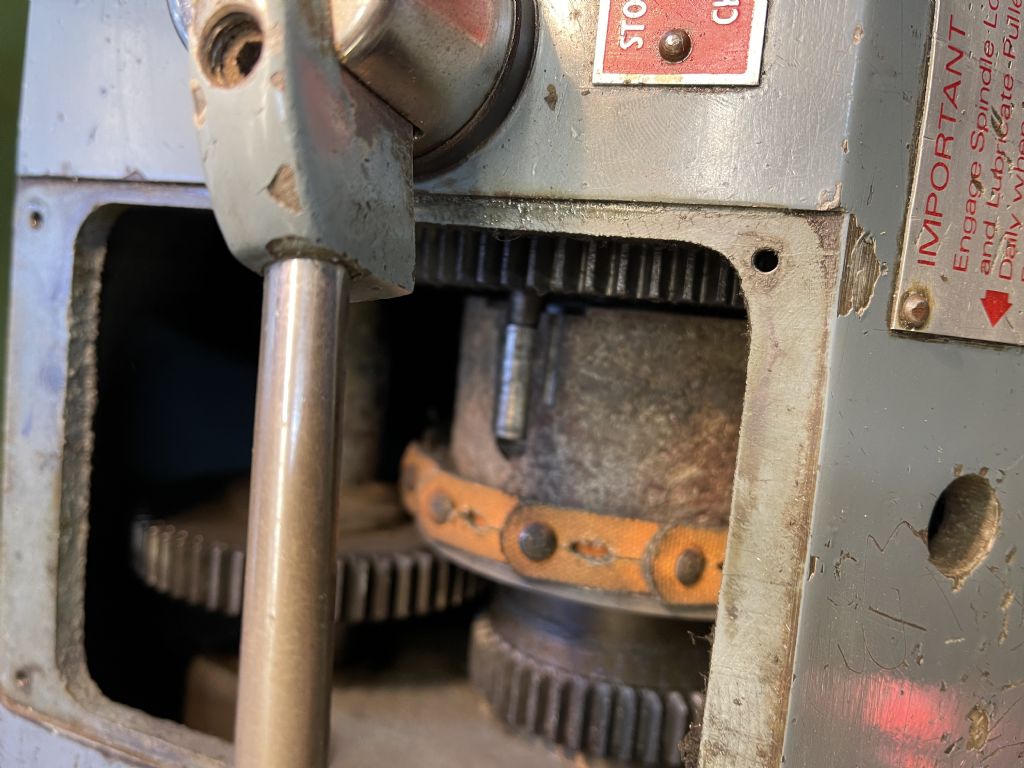

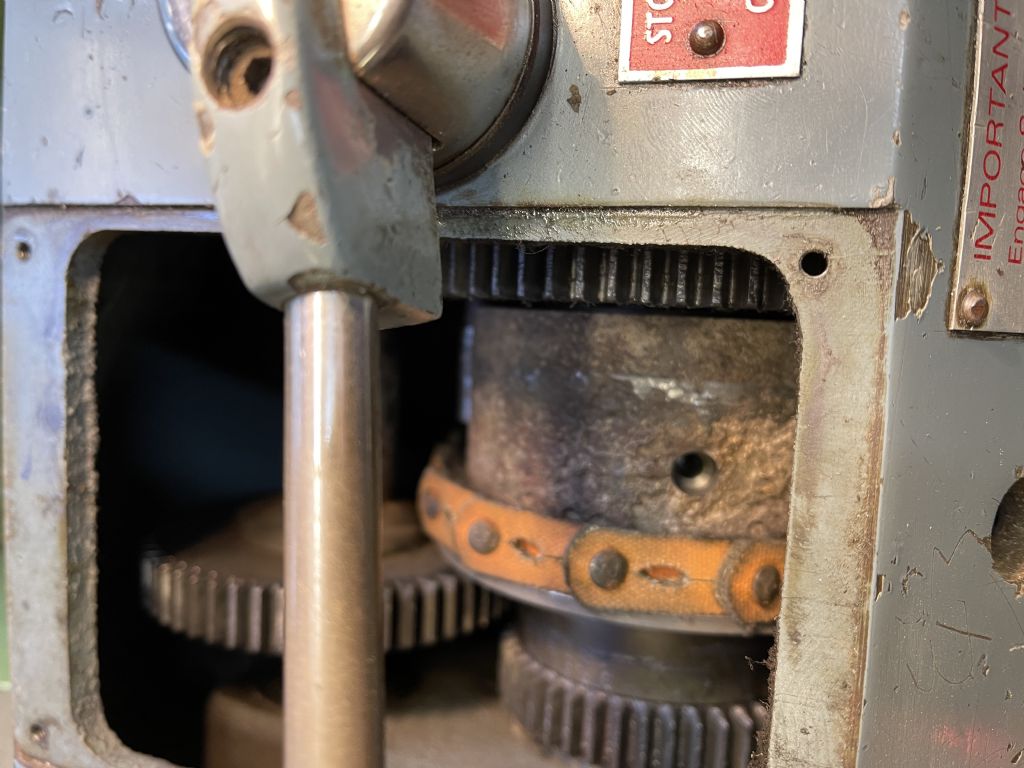

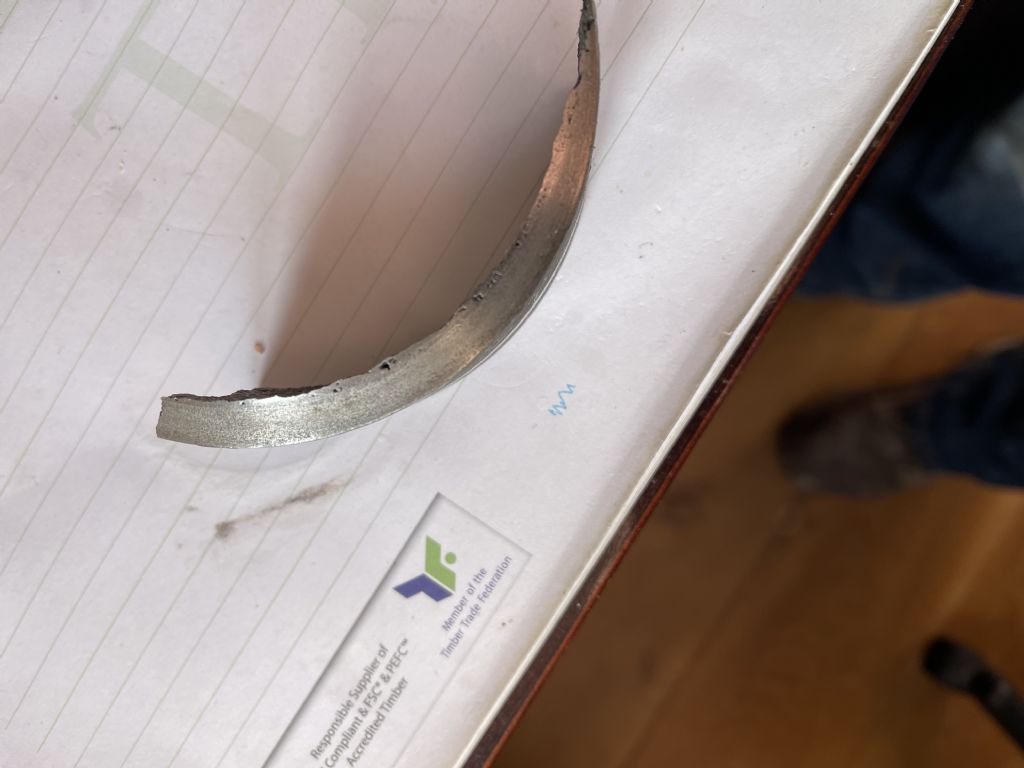

![v__7b36[1].jpeg v__7b36[1].jpeg](/wp-content/uploads/sites/4/images/member_albums/162324/883427.jpg)