I think this very simple question might be a product of my mathematical inadequacies, but I’ve been trying to cut hexagons on a mill using a rotary table to turn the bar (bronze) through 60° six times. It’s been a frightful banjax of which I am deeply ashamed.

Two nasties occur. Firstly the flats are not equally wide and secondly they are not true axially. I don’t think there is a problem with the rotary table, the chuck I’m using to hold the bar, nor the mill itself. Moreover, I think I may not be calculating the tangents correctly to ascertain the depth of cut (with an endmill) necessary to create equal flats.

Thus I think a collet block set is the answer.

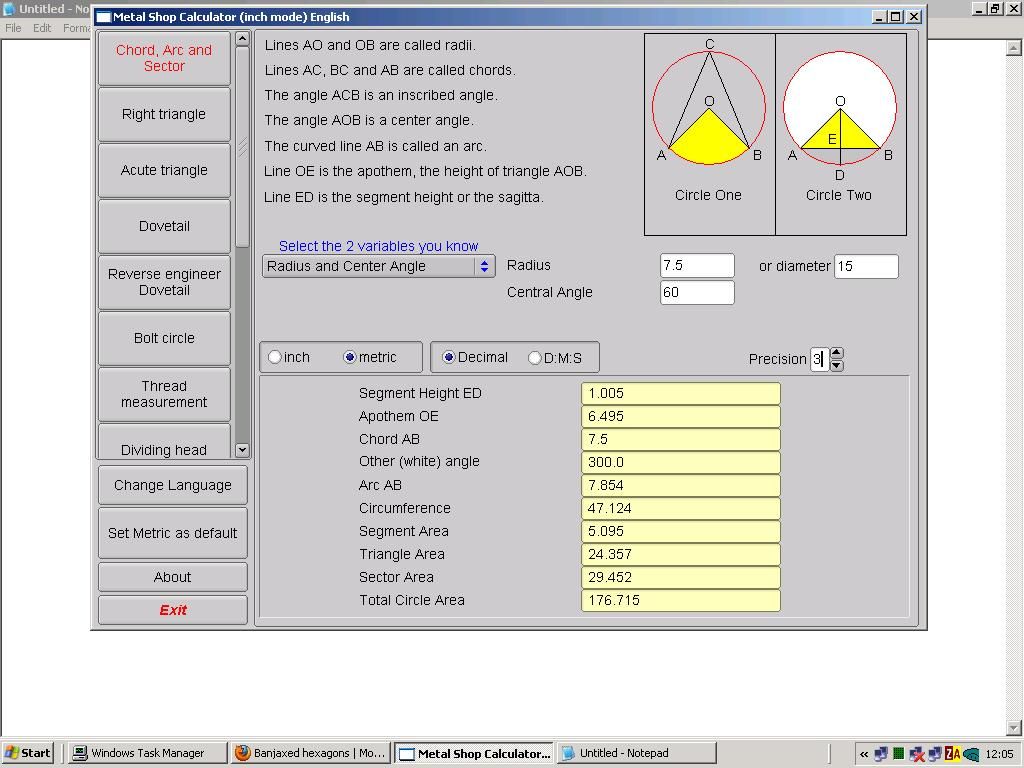

But what I don’t understand with collet blocks, is, again, how to cut to the correct depth. Obviously the dimensions of the blocks themselves don’t vary. So, for example, if one wished to cut a hexagon on a bar 15 mm in diameter you would start by putting the stock in the appropriate sized collet and clamping it in the block. But when you have the block clamped in the vice on the mill, how do you know how much to machine off for the first flat, before you turn the block for the next? Do you take, say, a millimetre, turn over, take another millimetre, turn again and so on; and keep going until you have a perfectly even (hopefully) ‘hex’?

Ian S C.