Posted by Clive Hartland on 08/10/2013 22:25:09:

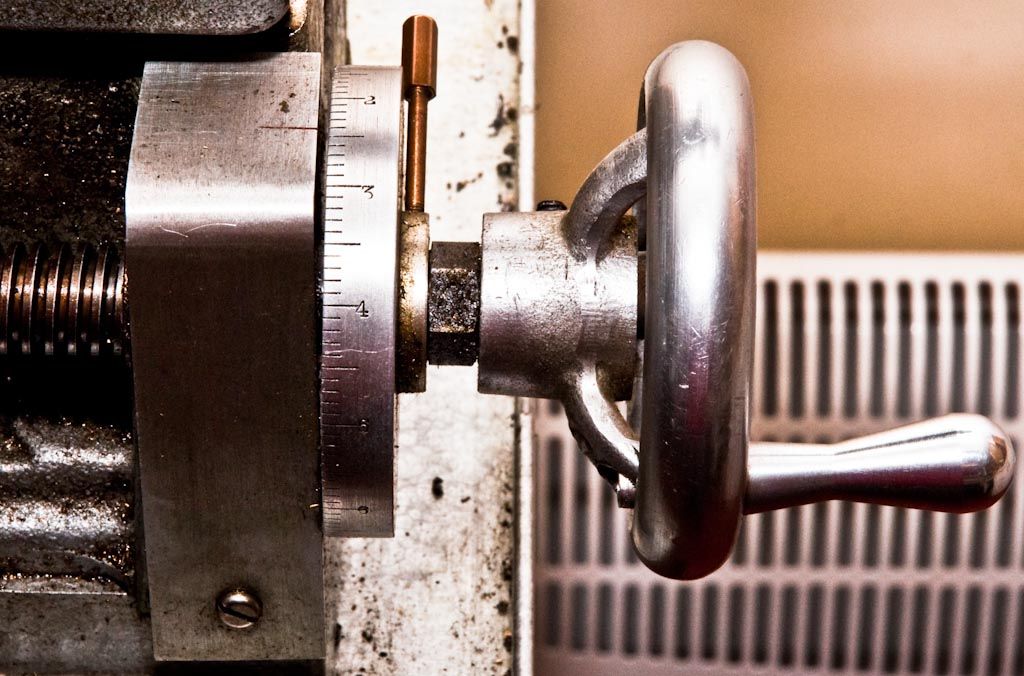

I have carried this mod out on my ML10 and one trick is that as you have to machine the bracket is that you take the bracket off a Myford Vert slide and machine it. Then swop onto the lathe, the one on the lathe then goes onto the vertical slide.

Otherwise you have to buy a spare one or do it on another lathe. It does smooth out the movement of the spindle and reduces the backlash. I also fitted a new nut.

I would also like to do something about the right hand end of the leadscrew, it is difficult to eliminate backlash there. Also I would like to modify the leadscrew graduated collar to a slipping scale. Any ideas ?

Clive

Edited By Clive Hartland on 08/10/2013 22:28:12

I would second your approach of modifying a spare bracket and then swapping it for the cross-slide bracket – its really the only practical approach. In my case, I replaced the bracket with one that I had fabricated, because it was also acting as a stepper mount for my CNC conversion, but the principle is the same. The improvement in the "feel" of the cross-slide movement is significant, and it eliminates all backlash except for play in the screw and nut.

Hemmingway do a kit for sorting out the RH leadscrew bracket – see:

**LINK**

I fitted this to my ML7, also as part of my CNC conversion, and it works a treat.

Regards,

Tony

Tony Jeffree.

Tony Jeffree.