John,

Modern motors are very good with VFD's the ones believe it or not that suffer are the older heavier Brookes type.

It has to do with the percentage of iron to copper in the build up.

A few years ago i ran a 1HP Brookes up on a Town Woodhouse mill to see what it would do. It was fine up to 85 hz and then performance dropped off at 90 hz it wasn't happy and by the time it got up to 105hz it was getting quite warm and sounding like it had lost a phase. Once back to 85hz it cooled down nicely and ran well.

Now fast forward to today and the motors are designed to accept VFD's

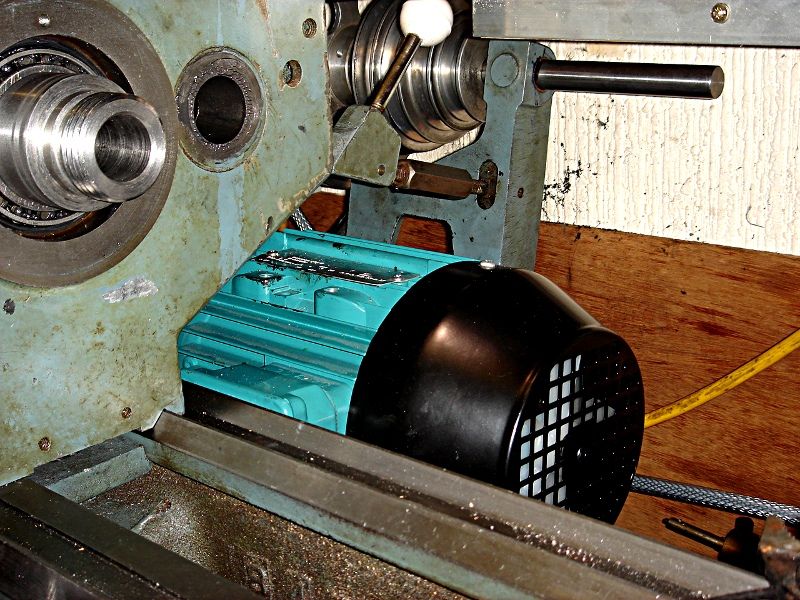

This is a standard off the shelf TEC [ Chinese ] 1.1Kw [ 1.5Hp ] 2800 2 pole motor.

They are then stripped down and the spindle pressed out , rotor bored and a new spindle fitted with integral ER32 fitting.

The end cover which is very skeletal is replaces with a solid cover to support double row angular contact bearings.

Everything is then rebalanced and then it's ready to run.

These run all day at this speed.

The next step from this but more expensive to to take that same motor, do exactly the same mods but have it rewound to run at 200hz this gives you a maximum of 12,000 rpm but then transforms that 1.5Hp motor into one capable of about 5Hp

These get done for CNC high speed router applications where they might have 5 heads on one machine. Not done any of these for a while because the water cooled spindles from China are now far more cost effective.

Muzzer.